Editor’s Pick

Subscribe to Our Newsletter

Engineering Product Design articles - Search & Learn

Sensors and Actuators

Electronics in Product Design

Guide to Internet of Things (IoT)

Internet of Things (IoT) refers to physical "Things" that gathers data and transfers them to cloud via Wi-Fi, Bluetooth, or cellular networks

April 21, 2023

Electronics in Product Design

Guide to NFC in product design

Near Field Communication technology enables wireless interaction between two NFC-compliant devices up to 10 cm apart

April 14, 2023

Stay Connected

Follow us

Follow us

Subscribe

Must Read

Manufacturing Processes

Pros and Cons of Fibre and CO2 Laser Cutters

Explore the advantages and drawbacks of fibre and CO2 laser cutters. Choose the laser cutting system that best fits your production needs.

Product Design Process

Engineering Product Design

Engineering product design combines creativeness, technical design skills, engineering science and analysis to create products

Manufacturing processes

Compression Moulding

October 3, 2023

Compression moulding is a manufacturing process which uses heat and pressure to mould plastic resins and thermosets into a desired shape

Surface finish

March 26, 2023

Surface finish is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.

12 Injection moulding defects and what causes them?

March 20, 2023

Injection moulding defects and their causes can help prevent by changing the part design, mould, material and processing parameters

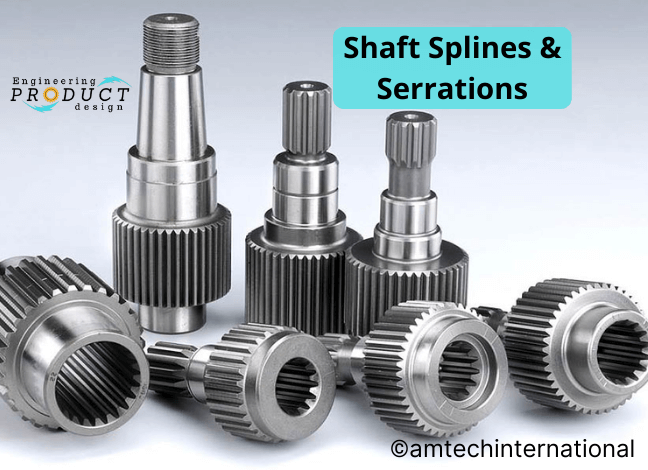

Shaft Splines & Serrations

Shaft splines & serrations are used to transmit rotational torque on the same axis and connect mechanical elements such as gears and pulleys.

Shaft key selection & shaft keyway design guide

February 13, 2021

Shaft key selection and keyway design should consider key types, correct fit, Key material, shaft material, load, fatigue & safety factors

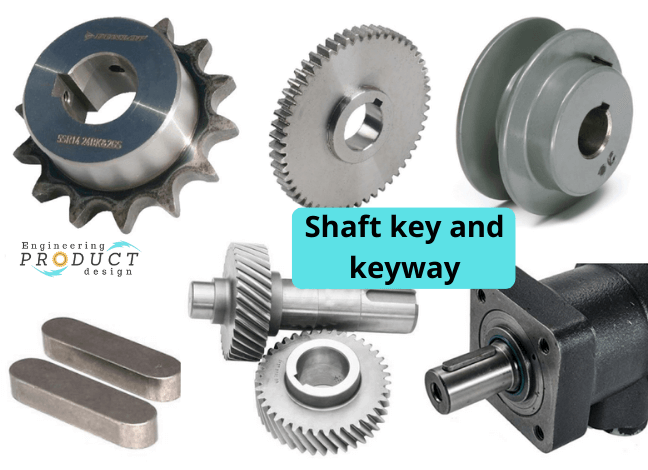

Shaft key and keyway

October 15, 2020

A Key is used on a shaft keyway to retain mechanical power transmission components such as gear drives and pulleys to transmit power

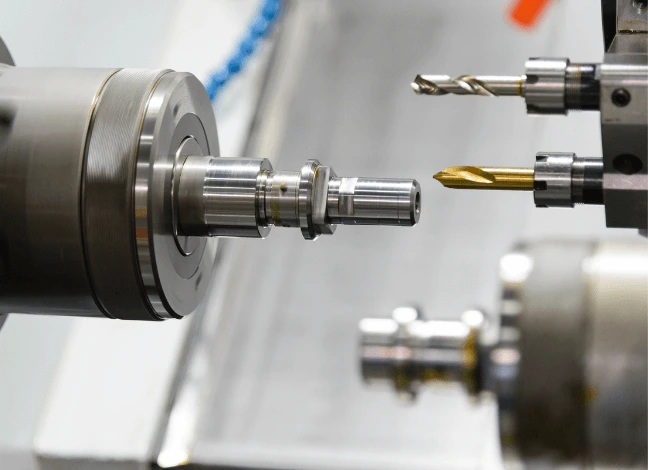

Aluminium Alloy for CNC machining

September 24, 2023

CNC machining of Aluminium alloy offers a range of advantages due to the material’s specific properties.

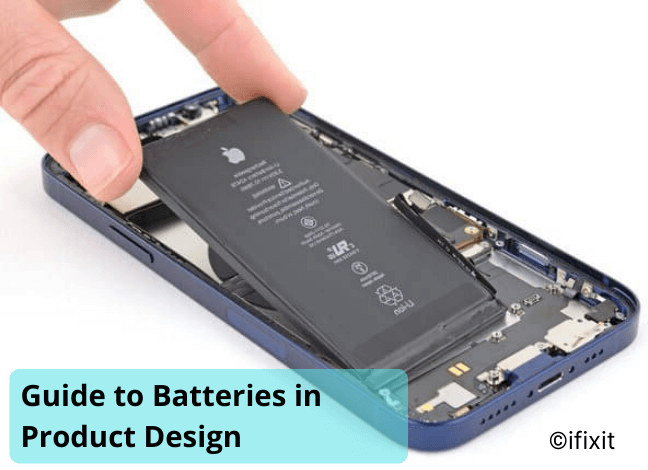

Guide to Batteries in Product Design

October 16, 2022

Primary and secondary batteries are electrochemical cells that convert stored chemical energy to electrical energy

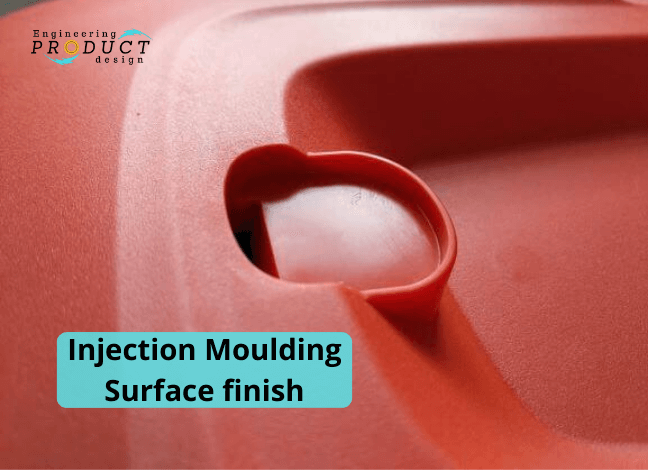

Injection moulding surface finish design guide – DfM

December 27, 2021

Injection moulding surface finish as per SPI and VDI classification systems – Gloss, semi-gloss, matte and textured surface finish

Tools & Techniques

Mechanical Elements

Concurrent Engineering (CE)

In Concurrent engineering product design methodology, different departments simultaneously work on different stages of engineering product development.

February 13, 2023

Engineering Design Analysis

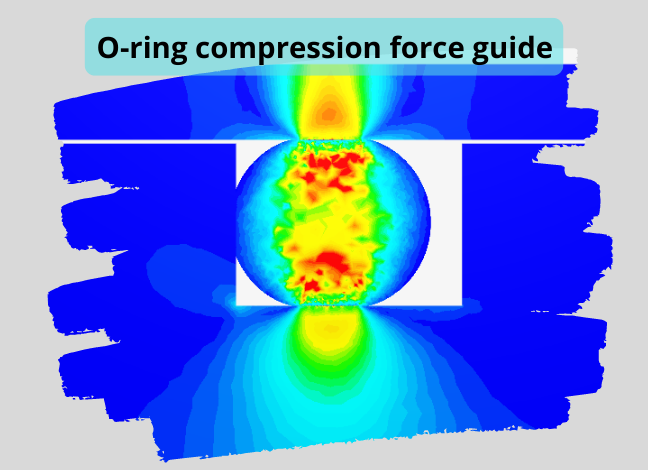

O-ring compression force

December 19, 2022

The force necessary to compress an O-ring to maintain an acceptable sealing line of contact is referred to as the O-ring compression force

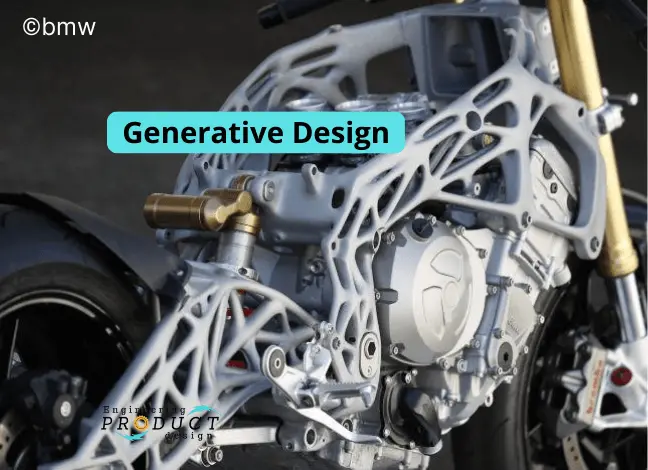

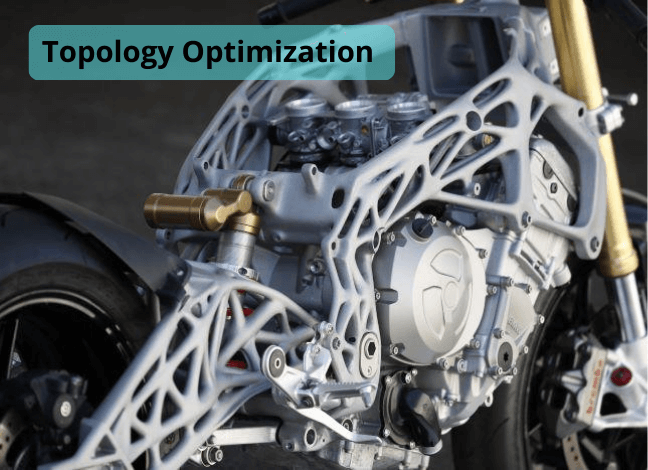

Introduction to Topology Optimization

December 18, 2021

Topology optimization is a process that optimizes material layout within a given ...