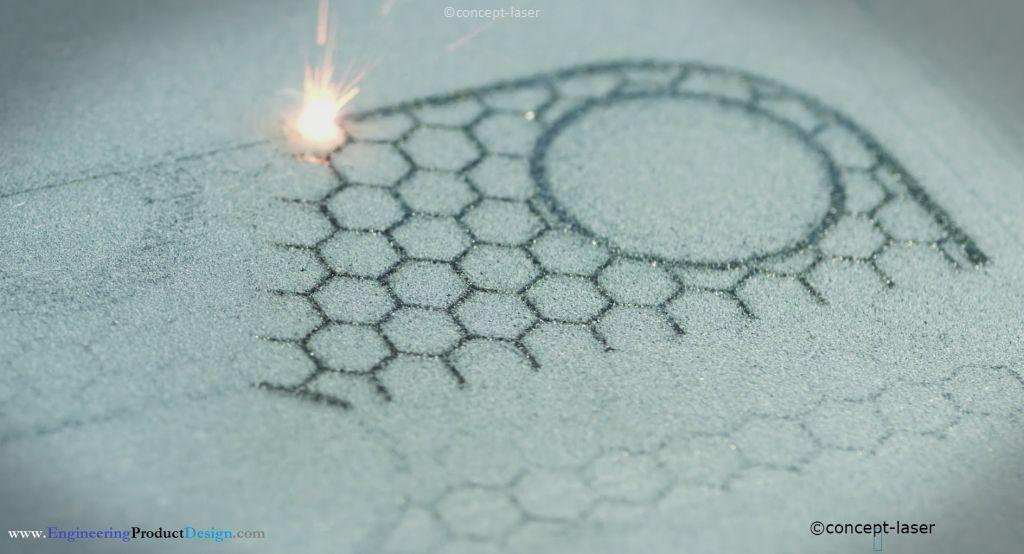

Direct metal laser sintering is an AM technique that involves melting and fusing layers of metallic powder to create a 3D object.

What is Direct metal laser sintering?

Direct metal laser sintering (DMLS) is an additive manufacturing technique that involves melting and fusing layers of metallic powder using a computer-controlled, high-power laser beam.

DMLS is the leading additive method for making metal prototypes and falls under Powder Bed Fusion. It is similar to selective laser sintering of plastic resin but is suitable for use with metals including aluminium, stainless steel, titanium, cobalt chrome and Inconel. It offers good accuracy and detail and excellent mechanical properties.

DMLS can be used for very small parts and features, and because it is an additive process, it can reproduce geometries that might be impossible to machine, such as enclosed spaces. Layers can be as thin as 20 microns, and tolerances on small features can be as small as ±0.002 inches. Secondary operations on parts produced by DMLS can include machined drilling, slotting, milling and reaming, and finishing procedures, including anodising, electro-polishing, hand polishing, and powder coating or painting.

Hot isostatic pressing (HIP), solution annealing, and ageing are treatment processes that can enhance the mechanical properties of parts by relieving residual stress that develops during the sintering process.

Advantages and Disadvantages of Direct metal laser sintering

Advantages of DMLS

- Capable of working with nearly any alloy

- Mechanical properties parts equal to conventionally formed parts

- Can make geometries that are impossible to machine or cast

Disadvantages of DMLS

- Relatively slow

- Expensive

- Requires expertise to make quality parts

- Usually requires expensive post-processing

DMLS design consideration

- Unwanted volume – remove unwanted material and sections as more material increases build time and material.

- Build volume – Reduce the size.

- Material to be solidified – Reducing the size and removing unwanted sections would decrease built time and cost.

- The number of layers dictates the time and cost. So print orientation and height affect the price

- Make external corners to be round rather than sharp.

- Overall, the ideal geometries are small, self-supporting parts that would be difficult to manufacture through machining, are too expensive for Investment casting, or are metal parts requiring short lead times.

DMLS Material Options

- Aluminium (AlSi10Mg)

- Stainless Steel (316L)

- Titanium (Ti6Al4V)

- Inconel 718

- Maraging Steel

- Cobalt Chrome

DMLS Parts Review

After getting an introduction to Direct Metal Laser Sintering (DMLS) parts from Protolabs few months ago, I had the opportunity to use their DMLS 3D printing service recently on couple of aluminium alloy parts for a prototype (Figure 1).

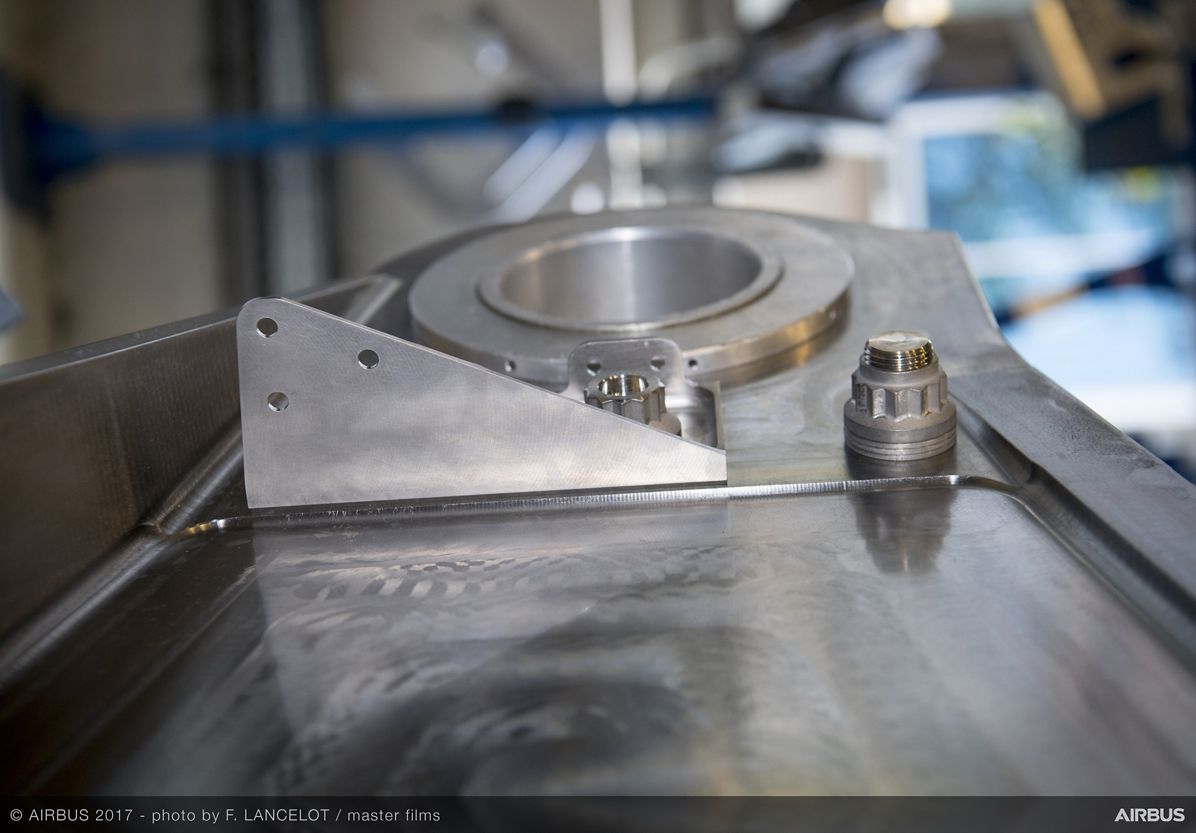

As demonstrated by Airbus recently, DMLS and other additive manufacturing techniques have advanced and reached a stage where it is now used to produce critical production parts. However, due to fundamental limitations of laser based processes for metal additive manufacturing, there is a significant ongoing need for these parts to be subject to additional machining operations such as threading holes, mating interface machining, polishing etc. before it can be used in an end product.

As the figure 1 shows, both parts had challenging features to machine for a one off without spending on tooling charges and set up costs. Because the parts were manufactured to test a concept by building a one-off prototype, 3D printing was by far the cheapest and quickest option.

Ordering process

It was fairly straight forward to open an account with Protolabs where you can get instant online quotations for both plastic and metal 3D printing (DMLS) parts. Once you select the metal 3D printing option, it allows you to select the material and resolution for the print as shown in figure 2. Material options include stainless steel (1.4404), titanium, aluminium alloy (AlSi10Mg) and maraging steel (1.2709).

Then 3D CAD files can be uploaded along with any special instructions, drawings, post operations etc directly into their online ordering portal. Getting quotation was instant as online tool calculates the cost by taking the material selection, build volume and the quantity into consideration.

Overall cost for the parts were about 60% cheaper than the CNC machining option and got delivered in 4 working days compared to 3 weeks for CNC machining.

Some of the other companies who offer metal 3D printing are;

- Materialise

- 3trpd

- 3dprintdirect

- Stratasysdirect

Dimensions

The dimensions that could be measured with a vernier caliper were all within +/- 0.1mm as per the print specification. For this reason for one-off prototype, especially if the final production part is a casting, DMLS is definitely a viable option. Though the build area of these new printers needs to be considered as the build volume is still small compared to what you can achieve with a casting.

Surface finish

The most prominent issue you would notice is the surface finish, especially if you are used to get the parts made using conventional CNC machining. As you can see from figure 3, the parts look like it’s been manufactured using Sand casting.

So depending on the application, the parts might need post processing such as polishing, aqua blasting etc to achieve a suitable finish. Surfaces such as bearing bores, threaded holes, interfacing faces, reamed holes, mating edges might need machining depending on its tolerances and functions.

Threads

3D model had a pilot hole for M3 threaded hole, so it can be threaded. Unfortunately as the figure 4 shows, the hole was not circular but more oval. But I did manage to tap the hole using a hand tap and it had enough thread engagement for a M3 grub screw to grip (Figure 5).

It is very difficult to predict the reason for the oval shape hole without knowing what orientation the part was printed. But generally holes on the vertical walls do not print well compared to horizontal plane.

Parts did function correctly within the assembly as intended but overall cost for a larger batch would be still cheaper using CNC machining than the 3D printing.

Direct metal laser sintering is not going to replace the CNC machining anytime soon because of the high cost and poor surface finish of the parts, but like any other manufacturing process it has its benefits and a place in the manufacturing field. So rather than looking at additive manufacturing as replacement to other manufacturing processes, we should look at how we could use it to overcome some of the short comings of conventional manufacturing processes.

DMLS/3D printed parts

Recently I had an opportunity to review some 3D-printed parts made by Protolabs, and I was pleasantly surprised by their quality and complexity. Parts shown in fig.1 were manufactured using an Additive manufacturing (AM) technique called Direct Metal Laser Sintering (DMLS) from Aluminium, Titanium, Stainless steel and Maraging steel.

DMLS falls under the group of additive manufacturing technology Powder bed fusion, where precise high-powered laser micro welds and fuses the metal powder to form components from a 3D CAD model in 7 steps. You can read more on how Powder Bed fusion and DMLS work and their characteristics here.

Parts can be manufactured using various metals such as Aluminium, Cobalt, Chrome Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Titanium Alloy, Chrome and Inconel through this method. The list of materials is growing as printer manufacturers, and additive manufacturing service providers such as Proto Labs are dedicating a significant part of their resources towards developing new materials.

As figure 1 &2 shows, it can produce geometries that are impossible to make using other conventional manufacturing process such as Casting, Forming and machining.

Metal 3D printing has come a long way since its inception and has been growing in leaps and bounds over the past few years, thanks to the investment in research and development by DMLS equipment manufacturer such as like SLM Solutions, EOS, 3D Systems, Renishaw and Concept-Laser.

When the technology emerged few decades ago it had the potential to revolutionise the manufacturing industry. Currently the industry uses to make prototypes, repairs of parts and production of non critical parts. But now it’s on the verge of moving onto production of direct critical parts. In September this year, Airbus announced that it has used a titanium 3d printed bracket (Figure 2) on its A350 XWB pylon production for the first time. (Read their statement here).

DMLS and other additive manufacturing techniques are going to completely change how engineering product designers view the design and production of metal parts. Engineering analysis such as FEA need to turn their attention to properties and performance of the new materials that will fundamentally determine the success or failure of printed parts.