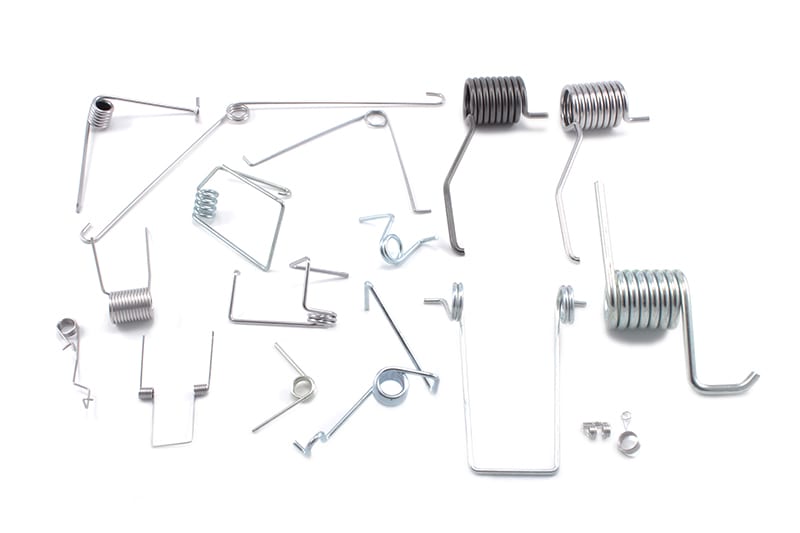

Mechanical springs such as compression, extension and torsional springs are elastic devices that store mechanical potential energy.

What are mechanical springs?

In their simplest form, mechanical springs such as coil springs, leaf springs, volute springs and compression springs are elastic devices that store mechanical potential energy when deformed by compression, extension or torsion. It is a device that changes its shape when an external force is applied and returns to its original shape when it is removed. The energy absorbed is stored in the spring and can be recovered if the spring returns to its original shape.

Mechanical springs are common in engineering product designs and can be found in almost any engineering product, from consumer to heavy industrial. Disassemble anything that involves mechanism, chances are you will find some type of spring. Most battery holders have springs to increase contact and keep it in place.

Types of mechanical springs

Spring types are classified into the following four groups based on how the force is applied.

- Compression springs

- Extension springs

- Torsional springs

- Constant force springs

Compression Springs

Compression Springs are open-coil helical springs wound or built to counteract compression along the wound axis. The most common metal spring design is helical compression. These coil springs can function independently, although they are often constructed over a guide rod or inserted within a hole. Applying a load to a compression coil spring pulls back against the load and strives to return to its previous length. Compression springs are one of the most efficient energy storage devices, providing resistance to linear compressing pressures.

Compression spring applications

Compression Springs are used in many applications, including automobile engines, huge stamping presses, and major appliances, including lawnmowers, medical equipment, cell phones, electronics, and sensitive instrumentation gadgets. The most basic installation is any place a push-button is required. Conical springs are commonly utilised in applications requiring low solid height and greater surge resistance.

Key Compression Spring Parameters to consider – Spring rate, Stress, Outside diameter, Hole diameter, rod diameter, free length, wire diameter, solid height, spring set, and load at solid height.

Extension Springs

Extension springs absorb and store energy while also resisting a pulling force. Extension springs are connected to other components on both ends. When these components separate, the extension spring attempts to bring them back together. These springs absorb and store energy while also resisting a pushing force. The starting tension of an extension spring dictates how tightly it is coiled. This starting tension can be adjusted to meet the load requirements of a specific application. Hooks, eyes, or other interface geometries are used on the ends of extension springs to attach to the components they link. They are typically employed to give return force to actuated components that stretch.

Extension spring applications

Automotive interiors and exteriors, garage door assembly, vice-grip pliers, carburettors, trampolines, washing machines, agricultural machinery, toys, and countless other applications are all possible using extension springs. Extension springs are available in various sizes, ranging from small medical devices to off-road machinery brake springs.

Torsion Springs

Torsion springs are helical springs with a torque or rotating force. Torsion spring ends are connected to other components, and as those components spin around the spring’s centre, the spring tries to force them back to their original position. Despite their name, torsion springs are susceptible to bending stress rather than torsional stress. By deflecting the legs along the body centerline axis, they can store and release rotational energy or keep a device in place statically.

This spring is typically close-coiled. However, it might have a pitch to decrease friction between the coils. They provide resistance to twist or rotational force. Torsion springs can be constructed to function in either a clockwise or counterclockwise spin, determining the direction of the wind.

Torsion spring applications

Torsion springs are frequently found in clothing pins, clipboards, swing-down tailgates, and garage doors. Hinges, counterbalances, and lever returns are examples of other application kinds. Torsion springs come in various sizes, ranging from microscopic torsion springs used in electrical gadgets to massive torsion springs used in chair control units. Unwinding from the free position is not suggested; the load should be applied in the direction of the wind. Torsion springs shrink in diameter and lengthen in length as they wind up. When design space is restricted, this should be taken into account. Torsion springs work best when supported by a rod, also known as a mandrel. The effects of friction and arm deflection on torque should be considered by the designer.

Constant Force Springs

Constant force springs, unlike the others described above, do not obey Hooke’s Law. Instead of exerting a proportionate force, these springs exert a nearly constant force. Constant force springs generally form a thin sheet metal wound firmly around a drum.

Constant force spring applications

A constant force spring is useful for applications that demand a constant load. Counterbalances, door closers, cable retractors, hose retrievers, tool head returns, cabinet furniture components, gym equipment, hairdryers, toys, electric motors, appliances, space vehicles, and other long-motion operations are just a few of the many applications for constant force springs.

Spring materials

The correct material may make or break a spring’s performance depending on the application. Factors such as operating temperature, corrosion resistance requirements, and required spring characteristics, fatigue, and creep must be considered during the material selection.

- High Carbon Steels – Music wire, hard drawn MB, Oil tempered MB

- Copper alloys – Phosphor bronze, Beryllium copper, brass, monel400, Monel K500

- Stainless steel – Stainless Steel 301, 302, 304, 316, 17-7 PH

- Nickel alloys – Inconel, Elgiloy, Nispan, Hastelloy

- Alloy steels – Oil tempered Chrome Vanadium, Oil tempered Chrome silicon

- Composite – Ultem

Spring coatings and surface treatments of springs

Metal springs can be treated with various spring coatings and surface treatments. Some are primarily responsible for corrosion protection, while others are designed to increase the hardness or wear resistance of the spring surface. Spring coatings are also utilised to shift size and modify physical qualities like reflectance and hue.

- Electropolishing

- Tumbling

- Shot peening

- Electroplating

- Electroless plating

- Chemical coating