The fabrication and manufacturing industry has seen revolutionary changes over the years. Thanks to new laser-cutting systems, how people shape and manipulate material has become easier than ever. However, two prominent players stood out in this pool of options: fibre lasers and CO2 lasers. Today, laser-cutting service providers offer both fibre and CO2 laser-cutting solutions to cater to the diverse needs of their clients.

According to industry reports, the global laser cutting machines market was valued at USD$5.59 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.6% between 2023 and 2030, driven by the increasing demand for precision cutting across various industries. In this blog, you’ll learn their pros and cons and how to weigh your considerations when selecting the cutting system that best fits your needs.

The rise of laser-cutting technology

Laser-cutting technology has come a long way since the first working laser was developed in 1960. Initially used for military and industrial applications, lasers soon found their way into manufacturing, revolutionizing how materials were cut and processed.

In the early days, CO2 lasers were the dominant force in laser cutting. However, the advent of fibre lasers in the 1990s brought a new level of efficiency and precision to the industry. These compact and energy-efficient lasers quickly gained popularity, particularly in industries that required cutting highly reflective metals with intricate designs.

Today, laser-cutting service providers have embraced these technologies, offering a wide range of services to meet the ever-evolving needs of their customers. Some providers even provide online laser cutting services, where customers can submit their models online for quoting, simplifying ordering and procurement processes and, thus, project management.

From small-scale prototyping to large-scale industrial production, laser cutting has become an indispensable tool in modern manufacturing.

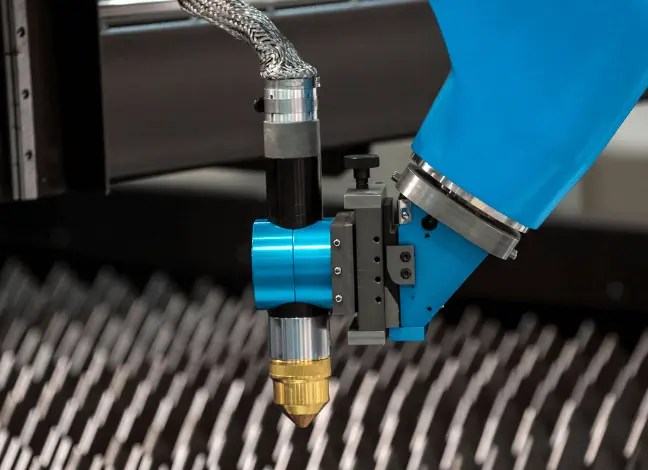

Fibre laser cutters

Regarding fibre laser cutters, their compact size belies their impressive capabilities. Here are the key advantages these laser-cutting powerhouses offer:

- Energy efficiency: Unlike CO2 lasers, fibre lasers use a solid-state laser source. Given its high-quality beam with a power of up to 4 kW, it uses less energy. It can contribute to 30% energy efficiency.

- Metal marvels: These lasers excel at cutting through highly reflective metals like copper, brass, aluminium, and stainless steel, making them invaluable in industries like electronics and aerospace.

- Low maintenance: With their robust laser source and minimal moving parts, fibre lasers require less frequent upkeep, translating into less downtime and higher productivity.

- Space-savers: Their compact footprint allows fibre lasers to fit seamlessly into even the smallest workshops or production facilities.

As impressive as fibre lasers are, they do have a few drawbacks that are worth considering:

- Material limitations: While fibre lasers handle thin to medium-thick materials with ease, they may struggle with thicker materials like acrylic, wood, or foam.

- Organic challenges: Their shorter wavelength makes fibre lasers less suitable for cutting or engraving organic materials like wood or leather, which may require a CO2 laser.

Despite these limitations, fibre lasers are popular for many applications thanks to their efficiency and capabilities.

CO2 laser cutters

When it comes to versatility, CO2 laser cutters are in a league of their own. These workhorses can handle many materials, making them a favourite choice for many industries. Here are its advantages:

- Material mavens: These lasers excel at cutting through organic materials like wood, acrylic, paper, and leather, making them popular among woodworkers, sign makers, and manufacturers.

- Thick material masters: With their remarkable precision, CO2 lasers can cut through thick materials like acrylic sheets or intricate wooden designs, delivering clean, smooth edges that will impress. In fact, one study noted that CO2 has a better quality in cutting material higher than 4mm than fibre laser cutters.

While CO2 lasers offer versatility and impressive cutting capabilities, they do have some drawbacks that should be considered:

- Energy inefficient: CO2 lasers are less energy-efficient than fibre lasers and have higher gas consumption, leading to higher operating costs over time.

- Metal challenges: These lasers struggle to effectively cut highly reflective metals like stainless steel and aluminium, which may limit their application in certain industries.

- Space and cooling needs: CO2 lasers have larger footprints and more substantial cooling requirements, which can pose challenges in space-constrained environments.

- Limited lifespan: The laser tube in CO2 lasers has a respectable lifespan, but it may not match the longevity of fibre lasers, necessitating periodic replacements.

Despite these drawbacks, CO2 laser cutters remain popular for many applications due to their versatility and impressive cutting capabilities on a wide range of materials.

Choosing the suitable laser cutter

Now that you understand the pros and cons of fibre and CO2 laser cutters, it’s time to figure out which best fits your requirements. After all, selecting the perfect laser cutting system can boost your efficiency, productivity, and return on investment. Let me walk you through the key factors to consider.

- Material compatibility

What materials will you mainly be working with? Suppose reflective metals like copper, brass, or aluminum are your bread and butter. In that case, a fibre laser cutter is probably your best bet. But if you need more versatility to cut diverse materials—wood, leather, and other organics—a CO2 laser may be the way to go.

- Thickness and precision

Think about the typical material thickness and how precise your cuts must be. CO2 lasers rock at cutting through thick stuff with intricate detailing. Fibre lasers, on the other hand, are super precise on thinner to medium-thick materials. Which one aligns better with your needs?

- Budget considerations

Can’t ignore the financial side, right? Both options come at different price points. Fibre lasers cost more upfront but could save you in the long run with lower operating expenses. CO2 lasers are generally the budget-friendly entry option if you’re initially strapped for cash.

- Space and environmental factors

Have you thought about the physical space and environmental conditions? Fibre lasers are compact and can handle a broader range of ambient temperatures—ideal if you’re tight on space or dealing with variable environmental conditions.

- Production volume and speed

If you’re churning out high volumes, laser speed is vital. Both technologies are fast, but fibre lasers could give you that extra edge on overall throughput thanks to their lower maintenance and higher energy efficiency.

Weigh all these factors against your unique goals and needs. I’m confident you’ll pick the perfect laser cutter—fibre or CO2—to maximize your operation’s potential!

As the demand for precision, efficiency, and versatility grows across industries, laser cutting technology has become a vital tool in the fabrication and manufacturing arsenal. Whether you opt for the energy-efficient and compact fibre laser cutter or the versatile and robust CO2 laser cutter, one thing is certain. These technologies are reshaping how we approach material processing.

Embrace the future of laser cutting, and equip yourself with the knowledge to make an informed decision to propel your business or hobby to new heights. With the right laser-cutting system in your arsenal, you can unleash your creativity, push the boundaries of innovation, and stay ahead of the curve in an ever-evolving manufacturing landscape.

Pingback: CO2 Laser Cutting vs. Fiber Laser: Which Is More Efficient?