Difference between Sand casting, Die casting and Investment casting

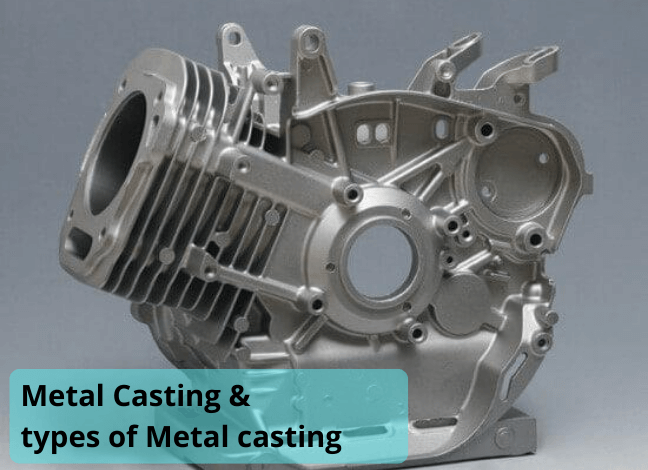

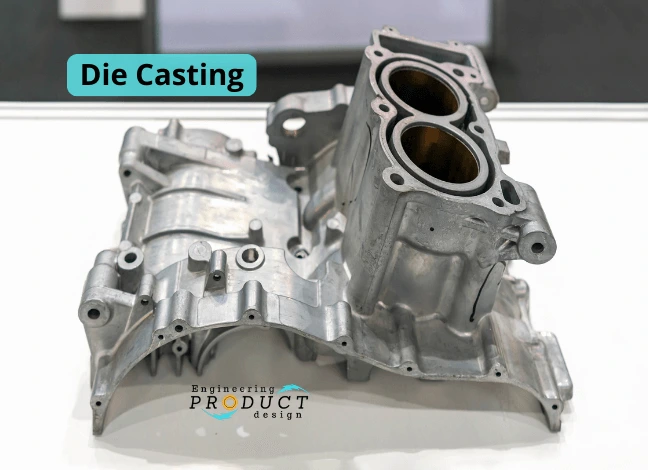

Sand casting, Die casting, and Investment casting are widely used casting processes worldwide to make metal parts for the consumer, automobile, medical and aerospace industries.

Difference between Sand casting, Die casting and Investment casting Read More »