Learn to design better products for 3D printing, CNC machining, injection moulding, casting and sheet metal fabrication and how to use DFMA techniques. Explore materials and post-processing methods.

- All

- 3D Printing

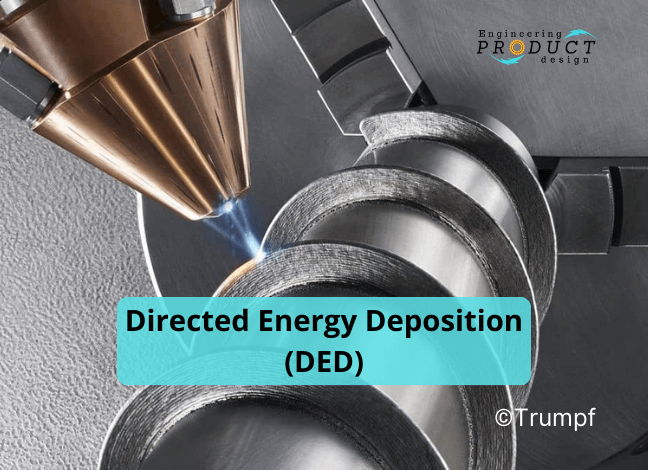

- Additive Manufacturing (AM)

- Casting processes

- Design for Manufacture & Assembly

- Electronics in Product Design

- Engineering Design Analysis

- Injection Moulding

- Machine Elements

- Manufacturing Processes

- Materials in Product Design

- Mechanical Design

- Mechanical Transmission

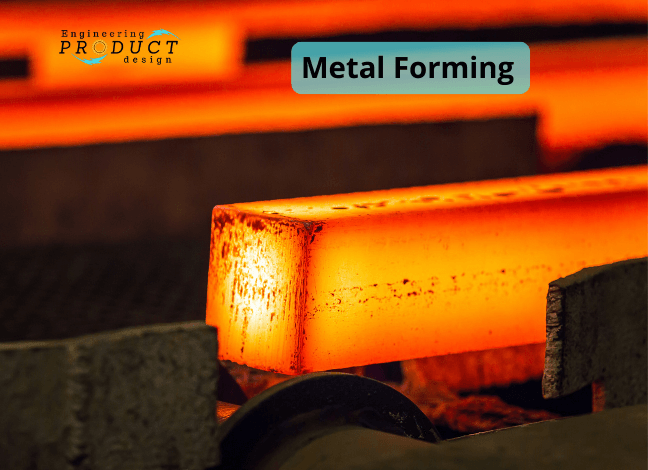

- Metal forming

- Product Design Guides

- Product Design Process

- Sensors & Actuators

- Tools and Techniques

Latest articles

Editor’s Pick

Manufacturing processes

Compression Moulding

June 12, 2024

Compression moulding is a manufacturing process which uses heat and pressure to mould plastic resins and thermosets into a desired shape

Advanced Machining Processes

June 11, 2024

Advanced machining processes are cutting-edge techniques used to shape, cut, or remove material from a workpiece

Metal Forming

May 30, 2024

During metal forming, the metal is plastically deformed by a force that exceeds the material yield strength where strain hardening occurs

Design Guides

Self-tapping screws for plastics

November 19, 2021

Self-tapping screws for plastic form or tap its threads when screwed into plastic and are installed into pre-drilled or moulded pilot holes

Mechanical Design

Threaded Inserts for Plastics

December 27, 2022

Threaded Inserts for plastics provide reusable metal threads and secure tight threaded joints in thermoplastics and thermosets. These threaded inserts have more pull-out force on a mating part than a self-tapping screw in plastics. They are also designed for easy and fast installation into plastics using in-moulding, cold, heat or ultrasonic pressing.

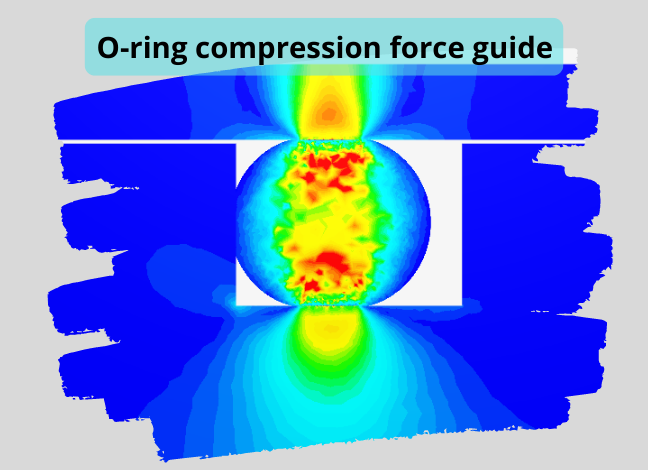

O-ring compression force

December 19, 2022

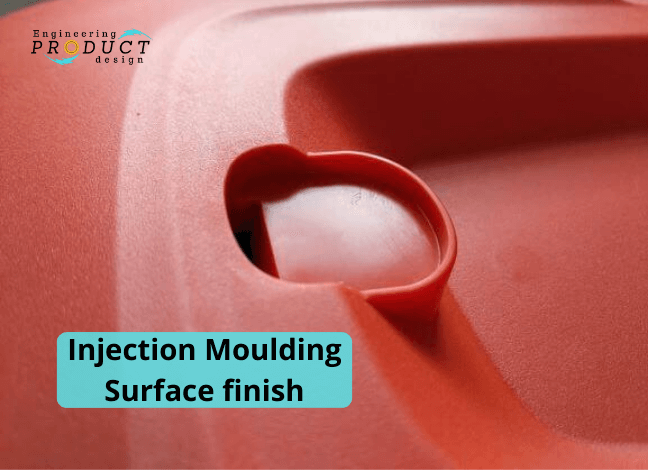

Injection moulding surface finish design guide – DfM

December 27, 2021

Additive Manufacturing

Material Extrusion – Fused Deposition Modeling (FDM)

June 21, 2024

In the material extrusion, plastic filament is fed through a heated extruding nozzle and deposited onto the building platform layer by layer.

Material Jetting

June 21, 2024

Material Jetting is one of the 7 types of Additive manufacturing technologies in which droplets of material are selectively jetted and cured to form part

Binder Jetting

June 20, 2024

Binder Jetting is an Additive Manufacturing process in which a binding liquid is selectively deposited to join powder material together to form a 3D part

Injection Moulding

Injection Moulding

February 2, 2023

Plastic Injection moulding is a widely used manufacturing process to produce plastic components due to its affordability, effectiveness, and high reliability.

Threaded Inserts for Plastics

December 27, 2022

Threaded Inserts for plastics provide reusable metal threads and secure tight threaded joints in thermoplastics and thermosets. These threaded inserts have more pull-out force on ...

Thermosets versus Thermoplastics

December 8, 2022

Thermoset plastics and thermoplastics sound similar, but their properties and applications differ vastly

More articles

What is Anodising – DFM guide to Anodising

November 29, 2023

Guide to Internet of Things (IoT)

April 21, 2023

Guide to NFC in product design

April 14, 2023

Design for Manufacture and Assembly (DfMA)

January 4, 2023

O-ring compression force

December 19, 2022

Guide to Microphones in Product Design

October 22, 2022