In investment casting, a wax pattern is coated with a refractory material to make a mould, which is then melted away before pouring molten metal into the cavity to solidify.

Contents covered in this article

What is Investment casting?

In Investment casting, a wax or suitable polymer pattern is coated by dipping into the refractory material slurry. Once the refractory material coating is hardened, then this dipping process is repeated several times to increase the coating thickness and strength. Once the final coating is hardened, the wax is melted, and molten metal is poured into the cavity created by the wax pattern. Once the metal solidifies within the mould, metal casting is removed by breaking the refractory mould.

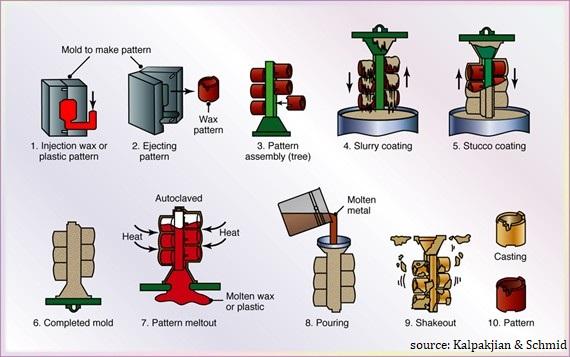

As shown in figure 1, the process can be summarised in the following steps – Master pattern making, Master die manufacture, Pattern making, Pattern assembly, refractory mould making, dewaxing, casting, and part removal.

Investment casting, known as a lost wax casting, is a precision metal casting process as it can make high accuracy and intricately detailed castings compared to similar manufacturing processes such as sand casting.

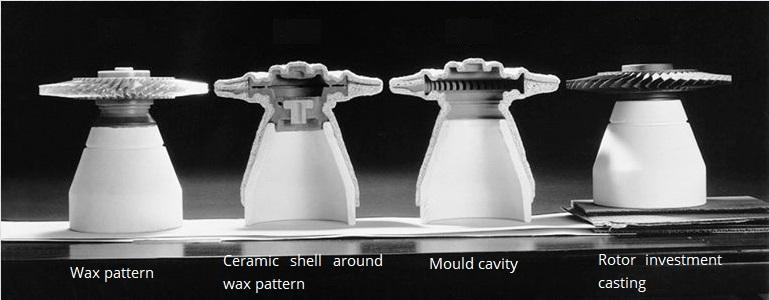

Typical parts include turbine rotors, gears, electronics enclosures, valves, jewellery and dental fixtures. Parts up to 1.5 m in diameter and weighing up to 1140 kg have been cast successfully in the past by this process, although the typical part would be, on average less than 100 mm in size and weighs less than 500g.

Figure 2 shows a gas turbine rotor casting at different stages. (Wax pattern, ceramic shell coating around the wax pattern, molten metal fill stage & final investment casting)

History of Investment casting

Although Investment casting has been used in various forms since it was first used by ancient Egyptians between 4000 and 3000 B.C, it was only after World War II its industrial importance and popularity grew due to the growing demand for parts for aircraft engines and the airframe sector.

Lost wax casting had changed from the days when clay was packed around the bee’s wax pattern to the use of ceramic shells and the introduction of special dewaxing ovens etc.

The high manufacturing cost of master dies has traditionally limited Investment casting to large production quantities. Still, the introduction of 3D printing of wax patterns in recent years has eliminated the manufacturing cost of dies and enabled their use for shorter runs.

Advantages and disadvantages of investment casting

Advantages of Investment casting

- Parts with extremely complex shapes and intricate features can be cast as a single piece using investment casting

- With short length or shallow depth feature, thin sections down to 0.40 mm (0.015 in) can be cast without cold shut defects

- Lost wax casting has excellent dimensional accuracy and tighter tolerances of 0.075 mm (0.003 in) are easily achievable.

- Compared to similar manufacturing processes, Investment casting can achieve an excellent surface finish without any post-processing. Typically around 1.3 – 0.4 microns RMS Ra

- It offers almost unlimited freedom in terms of investment cast materials, but the most common materials used include Aluminium alloy, cast iron and non-ferrous alloys. The process is particularly attractive for high-temperature alloys.

- Draft on walls are not required but if a master die is used to make wax patterns then draft on the face would help the pattern making process easier.

- Since there are no parting lines, the cast would not have any flash. But the wax patterns might have parting lines from the master die.

- Additional machining can be eliminated or reduced and an allowance of as little as 0.4 to 1 mm (0.015 to 0.040 in.) is usually enough.

- Excellent dimensional precision can be achieved in combination with very smooth as-cast surfaces. These capabilities are especially attractive when making products from the high-melting temperature, difficult-to-machine metals that cannot be cast with plaster- or metal mould processes.

- The wax used can usually be recovered for reuse.

Disadvantages of Investment casting

- Compared to other methods of metal casting such as Die casting and sand casting, lost wax casting involves many complex steps making the process relatively expensive. But some of the steps can be automated for certain products. It can be more expensive than die casting or sand casting, but per-unit costs decrease with large volumes.

- The high cost of dies to make patterns has traditionally limited investment casting to large production quantities

- The high cost is also due to specialised equipment requirements, costly refractory material, and high labour cost

- Parts are difficult to cast if they require cores, got holes smaller than 1.6 mm or deeper than 1.5 times the diameter

How does Investment casting work?

So what are the Investment casting process steps?

Investment casting has been creating near-net shape products successfully in various forms for thousands of years. Although the introduction of new materials and manufacturing techniques in the last few years has led to some changes and improvements, the investment casting process steps have largely remained unchanged.

In general, investment casting sometimes referred to as lost wax casting can be summarised into the following 8 steps.

Step 1 – Master pattern creation

A master pattern is created from wax, clay, wood, steel or plastic by either a specialised mould maker or sculpture artist as per final product requirement. These are made considering both wax and casting material shrinkage, hence it’s called, “master pattern” for having double shrinkage allowance. Figure 3 below shows a wooden master pattern and its casting.

Depending on the size, shape and material used, this process may take some trial and error to get the size and shape correct, therefore making these moulds expensive.

Step 2 – Master die / Mould / Mold

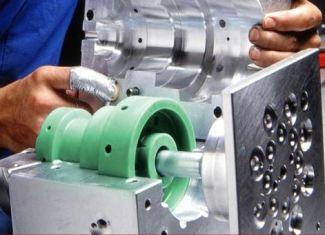

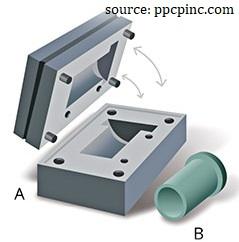

A mould, known as the master die to create wax patterns is made to fit the master pattern by either casting or machining. Technology advancement in tooling and CNC machining has enabled machining a master die from a material such as steel and aluminium without the need for a master pattern as shown in figure 4.

If the master pattern is made out of steel then the master die can be cast directly from the steel master pattern using metal with a lower melting point than steel. Silicone rubber moulds are also used extensively these days due to their simplicity of using to cast a mould directly from a master pattern. Silicone rubber moulds would withstand casting temperature up to about 310oC (590oF).

The master pattern and master die must be designed taking shrinkage of pattern wax, refractory material and the metal cast material into consideration. It’s also good practice to add machining allowances for post-machining on tighter tolerance surfaces. Another important aspect of two-part master dies or moulds is mould alignment locators. Mould locators are critical in aligning the two halves to produce accurate parts without large parting lines or parting line shifts. (Figure 5)

Step 3 – Pattern

The patterns are then made by injecting or pouring molten wax into the master die and allowing it to harden (Figure 6). Sometimes it’s also used as a coating where inside cavity walls of the die are coated with wax to get a hollow pattern. This coating is repeated until the desired pattern thickness is reached usually about 3 mm (0.12 in). Latter suitable only for simple parts. Sometimes patterns are also made using suitable polymers and frozen mercury.

Recent advances in rapid prototyping have made the production of patterns directly from a CAD file possible, either as a master pattern or as wax patterns, consequently reducing the cost. 3D printing technologies such as stereolithography, selective laser sintering (SLS), fused deposition modelling (FDM) and poly jetting are increasingly used to create patterns. These rapid prototyping technologies use a layering technique in their creation so post-processing is required in most cases to ensure a good surface finish.

Cores are generally made from soluble wax or ceramic where soluble wax cores are dissolved out of the patterns pre-processing, while the ceramic cores remain and are removed after solidification of the metal casting.

In a process called “Chasing” imperfections such as parting lines and flashings are removed using a heated metal tool and release agents, such as silicone sprays are also used to assist in pattern removal and avoid any damage to the patterns.

Step 4 – Pattern assembly

The wax patterns are then assembled onto a common wax sprue. Sprue is a channel through which molten alloy can reach the mould in an investing ring after the wax has been eliminated.

Using heated tools and melted wax, a number of wax patterns can be attached to a central sprue and runner system to create a pattern cluster or a tree. Depending on the size of the parts, up to several hundred patterns can be assembled onto a tree increasing productivity. (Figure 7)

Sprue will hold the wax pattern to avoid distortion during the casting process, creating a channel for the molten wax to escape from the mould and then allowing the molten material to flow into the mould.

Step 5 – Dipping coating

The pattern is then dipped into a slurry of finely ground refractory material and then drained to create a uniform surface coating called a “Prime coat”. During this stage a very fine particle size is deposited to create a thin but very smooth layer of investment material, to ensure a smooth surface and intricate detailed final product. Very fine silica and other binders, including water, ethyl silicate, and acids are commonly used as refractory materials.

After the initial layer has dried, the pattern is dipped and coated repeatedly to increase its thickness for better strength. This second stage of the dipping process is called “stuccoing” in which sand or other refractory aggregate is rained over the wet surface to increase the thickness (5 to 15 mm [0.2 to 0.6 in.]) and strength.

Sometimes as an alternative method, the single-dipped pattern cluster is inserted into a permeable flask upside down and liquid investment material poured around it. The flask is then vibrated to remove entrapped air and ensure that the investment material surrounds all surfaces of the mould tree.

This is then left to dry completely, which can take between 16 to 48 hours. Drying can be accelerated by applying a vacuum or minimising environmental humidity.

Step 6 – De-waxing and firing

Once the refractory material mould has fully dried and cured, they are turned upside down and placed in an oven or special purpose de-waxing autoclave, where the wax can melt and run out (figure 9), and any subsequent residue vaporized. (These simulations show how specialised de-waxing machines work video 1 or video 2)

The removal of pattern wax from the mould is an important stage in the investment casting process and when performed incorrectly will reduce the batch yield. De-waxing is also one of the main reasons for shell cracking. Shell cracking is the single most common investing casting defect.

Fundamentally there are two main methods for de-waxing, flash fire or autoclave (steam). Steam autoclaves are the preferred choice due to their uniform heating which would reduce the stress on the material.

The mould is heated (90oC–175oC) and held in an inverted position for a few hours (about 4 – 12 hours) to allow the wax to melt and run out. Pattern wax is usually recovered and recycled. Then it’s heated and maintained at an elevated temperature (650oC–1095oC) for a few hours (3-6 hours), to drive off the water of crystallization and burn off any residual wax. The duration and the temperatures depend on the metal cast material.

Most shell failures occur during the dewaxing stage as the waxes used have a greater thermal expansion coefficient than the refractory material. Hence wax expands more than the investment material and introduces a possible stress fracture on the mould. To reduce this effect the wax can be heated rapidly so the outer wax melts quicker and allow the remaining wax to expand without stressing the mould. Autoclaves shown in figure 10 are also used to heat reduce this effect as the heating cycles can be more uniform and controlled more accurately.

Step 7 –Preheat & Casting

Mould is then pre-heated in preparation for pouring. Preheating allows the metal to stay in the molten state longer so that it can better fill all mould details and increase dimensional accuracy. If the mould is left to cool, any cracks found can be repaired with ceramic slurry or special cement. Mould heating also gives better dimensional control because the mould and the metal can shrink together during cooling.

Molten metal up to 3000oC is poured into the hollow mould and then left to cool. While gravity pouring is the simplest, other methods may be used to ensure complete filling of the mould. When complex, thin sections are involved, mould filling may be assisted by positive air pressure, tilt casting, vacuum casting or centrifugal casting process.

Step 8 – Knockout & post-processing

After the metal has solidified, techniques such as mechanical chipping, hammering, vibrating, high-pressure water jetting and media blasting are used to break the mould and remove the metal casting.

Then individual castings are cut away and excess metal is removed. The sprue is cut off and in most cases reused. The part is then post-processed as per the final product requirement such as post-machining, heat treating, surface treatments, painting etc.

Investment casting and 3D printing

The investment casting method benefits from additive manufacturing in a variety of ways. The most obvious advantage is that we can do away with moulds, and the method can immediately print patterns with excellent details.

When combined, 3D printing, the latest manufacturing technique and investment casting, the oldest metal forming technique, can cut development time and tooling cost during engineering product development.

Skipping the most common approach of making a master pattern, mould and wax patterns, the 8 step investment casting process could be reduced to fewer steps. Hence considerably reducing production time from weeks to days.

Benefits of 3d printing investment casting patterns

- Reduce tooling costs by making modest volumes of casted components from a CAD model 24-48 hours.

- Reduce the time it takes to create tooling.

- Reduce the amount of money spent and the amount of space required for tool storage.

- Deliver non-moldable goods

Case Study – Ferrari’s 488 Pista

The Role of Investment Casting in Ferrari’s 488 Pista

In February 2018, Ferrari took the automotive world by unveiling its 488 Pista at the Geneva Motor Show in Switzerland. Boasting a record-breaking 710bhp turbocharged engine, Ferrari proudly proclaimed the 488 Pista as the pinnacle of V8 performance in its storied history. Central to this achievement were advancements in engine power and significant reductions in vehicle weight, achieved through innovative engineering techniques.

The Ferrari 488 Pista culminated years of research and development, drawing heavily from the company’s racing expertise, particularly its 488 GTE and 488 Challenge models. One of the standout features of the 488 Pista was its remarkable weight reduction of nearly 90kg compared to its predecessors. This weight reduction was achieved through material advancements and aerodynamic refinements.

Investment Casting – The engineering community was particularly interested in Ferrari’s utilisation of investment casting, notably in producing its Inconel exhaust components. Investment casting had long been favoured for its ability to produce intricate parts with fine details, but its high cost, especially for smaller batch production, had been a limiting factor. However, advancements such as 3D printing of wax patterns had significantly reduced the cost barrier associated with tooling, Investing casting more accessible for high-performance applications like the Ferrari 488 Pista.

Technological Innovations – Key technological advancements, such as Vacuum Induction Melting (VIM) and dewaxing autoclaves, were crucial in using high-temperature-resistant superalloys like Inconel 625 in investment casting. These alloys offered unparalleled thermal fatigue strength, oxidation, and heat resistance, making them ideal for extreme automotive applications.

Conclusion: Ferrari’s 488 Pista’s success is a testament to the transformative potential of investment casting in automotive performance. By leveraging advancements in material science and manufacturing technologies, Ferrari pushed the boundaries of what was thought possible regarding engine power and weight reduction. As vacuum induction melting, dewaxing autoclaves, and 3D printing evolve, investment casting stands poised as a cornerstone of innovation, opening new doors for the future of automotive engineering.

References and recommended reading

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth ed.). London: Pearson.

- Black, J. T, & Kohser, S. Ronald. (2012). Materials & Processing in manufacturing (Eleventh ed.). London: John Wiley.

- Beeley, Peter, (2009). Foundry Technology (Second ed.). Oxford: Butterworth-Heinemann.

- Groover, P. Mikell, (2010). Fundamentals of modern manufacturing (Fourth ed.). Oxford: John Wiley.

- Investment casting process graphics. (n.d.). PPCP inc. Retrieved January 2018, from http://ppcpinc.com/wp-content/uploads/2014/06/ppcp_process-graphic.jpg