Generative design is a powerful tool that can lead to new and innovative designs that are difficult or impossible to achieve through traditional design methods.

What is Generative Design?

Generative Design (GD) is a design method that uses algorithms and artificial intelligence to generate multiple design solutions based on specific design criteria and constraints. This approach allows designers to explore many design options and variations and quickly evaluate and refine them based on specific requirements, such as functionality, performance, and aesthetics.

In generative design, the designer inputs the design criteria, such as the desired performance, materials, and manufacturing processes, into design software, which then generates multiple design solutions. The designer can then evaluate and refine the generated designs, selecting the best options and adjusting the parameters to achieve the desired results.

Generative design is used in various fields, including architecture, engineering, product design, and manufacturing. It can lead to more efficient and innovative design solutions that would be difficult or impossible to achieve through traditional design methods. Using algorithms and artificial intelligence also helps speed up the design process and reduces the need for manual iterations, saving time and resources.

Applications of Generative design

Generative design has a wide range of applications across various industries and fields, including:

- Architecture: It can generate designs optimised for specific performance criteria, such as energy efficiency, structural stability, or natural light.

- Engineering: GD can be used to design lightweight, high-performance structures, such as aircraft and automotive parts, or to optimise the performance of mechanical systems, such as pumps and turbines.

- Product Design: GD can be used to design consumer products, such as furniture and household goods, optimising for factors such as ergonomics, materials, and manufacturing processes.

- Manufacturing: GD can optimise the production process, reduce waste, increase efficiency, and improve product quality.

- Fashion Design: GD software can be used in the fashion industry to design and create new and innovative garments and accessories, optimising for factors such as comfort, functionality, and aesthetics.

- Industrial Design: GD can design complex, high-performance products like medical devices and industrial machinery.

- Robotics: GD can be used in robotics to design and optimise the performance of robots and other automated systems.

Generative design is a powerful tool that can lead to innovative designs that would take more work to achieve through traditional design methods. In addition, its ability to quickly generate and evaluate multiple design options makes it an ideal tool for designers, engineers, and manufacturers looking to optimise their designs for specific performance criteria and constraints.

Generative design process steps

The steps involved in the generative design process are:

- Define design goals – The first step is clearly defining the design goals, including performance criteria, functional requirements, and constraints.

- Input parameters – Input parameters, such as material properties, manufacturing methods, and geometric constraints, are defined and entered into the generative design software.

- Generate design options – The generative design software generates many design alternatives based on the input parameters and design goals.

- Evaluate design options – The generated designs are then evaluated using simulations or other analysis tools to assess their performance against the specified design goals.

- Select the optimal design – The most optimal design is selected and further refined if necessary based on the evaluation results.

- Fabricate and test – The final design is fabricated and tested to validate its performance and ensure that it meets the design goals.

- Iterate – The generative design process is iterative, and the steps can be repeated until the desired design is achieved. The process can also be repeated to generate and evaluate different design options, trade-offs, and alternatives.

Advantages and Disadvantages

Advantages

The generative design offers several advantages over traditional design methods, including:

- Increased creativity and innovation: GD allows designers to explore many design options, leading to more creative and innovative solutions.

- Improved efficiency and speed: Generative design automates many manual and repetitive tasks involved in the design process, saving time and increasing efficiency.

- Better optimisation and performance: GD uses algorithms to optimise design solutions for specific criteria, such as performance, materials, and manufacturing processes, leading to better overall performance and functionality.

- Enhanced collaboration: Generative design allows for better collaboration between designers, engineers, and other stakeholders, enabling a more integrated and efficient design process.

- Increased diversity and inclusivity: Generative design allows for the exploration of a larger number of design options, leading to a more diverse and inclusive design process that can better meet the needs of a wide range of users.

- Enhanced scalability: It can optimise products and systems at different scales, from small consumer products to large-scale infrastructure projects.

- Improved sustainability: It can optimise designs for sustainability, reducing waste, improving energy efficiency, and reducing environmental impact.

Generative design is a powerful tool that can revolutionise the design process and lead to better, more efficient, and more innovative design solutions. Its ability to automate and optimise the design process makes it an ideal tool for designers, engineers, and manufacturers looking to improve their design outcomes.

Disadvantages

While generative design offers many advantages, there are also some potential disadvantages to consider, including:

- Dependence on technology: Generative design relies heavily on technology, including algorithms and software, and is therefore vulnerable to technical issues, such as software bugs or compatibility problems.

- Limited control: Generative design often involves surrendering a certain degree of control over the design process to the software, resulting in designs outside the designer’s vision or goals.

- Bias in algorithms: Design algorithms are only as good input training data. They may exhibit bias or discrimination if the training data is diverse and representative.

- High cost: Software can be expensive and require specialised skills and knowledge, making it inaccessible to many designers and engineers.

- Limited understanding: Generative design is a relatively new field. Many designers and engineers may need a deeper understanding of the algorithms and processes involved, leading to limitations in customising and optimising designs.

- Lack of tactile feedback: Generative design typically relies on computer-based simulations, which can be limited in providing the designer with a sense of touch, movement, or other physical feedback.

- Need for human intervention: Although generative design automates many aspects of the design process, it still requires human intervention to evaluate and refine designs and to ensure that the final designs meet the designer’s goals and requirements.

Despite these potential disadvantages, generative design is still a valuable tool for designers and engineers, offering many benefits that can improve the design process and lead to better outcomes. It is essential to consider the advantages and disadvantages of generative design carefully and to choose the right software and tools to meet your specific design needs and goals.

Generative design vs topology optimisation

Generative design and topology optimisation are two design processes that use computational algorithms to generate design alternatives and optimise the design for specific performance criteria.

Generative design uses artificial intelligence, machine learning, and simulation to explore a wide range of design options and then selects the most optimal design based on specified criteria. The process involves defining design goals, constraints, and parameters and allowing the computer to generate and evaluate multiple design options.

Topology optimisation uses mathematical algorithms to optimise the shape and structure of a design to meet specific performance requirements, such as strength, weight, stiffness, or manufacturing costs. The process involves defining loads, boundary conditions, and design constraints and then using an optimisation algorithm to find the optimal distribution of the material in the design.

In summary, while generative design and topology optimisation use computational algorithms to optimise designs, the generative design focuses on exploring a wide range of design options and selecting the best. In contrast, topology optimisation focuses on optimising the distribution of material to meet specific performance requirements.

Generative design vs parametric design

Generative and parametric design are two approaches that use computer algorithms to aid the design process.

Parametric design is a design approach that uses a set of input parameters, or variables, to define a design. The input parameters are determined by the designer and can be used to control various aspects of the design, such as size, shape, material, or functionality. In addition, the design can be quickly modified by changing the input parameters, making it an efficient method for exploring design alternatives and variations.

On the other hand, the generative design uses artificial intelligence, machine learning, and simulation to generate design alternatives based on specified design goals and constraints. The process involves defining design goals, constraints, and parameters and then allowing the computer to create and evaluate multiple design options, often producing designs that may have yet to be considered by a human designer.

In summary, the parametric design gives the designer more control over the design by allowing them to define and modify input parameters. In contrast, the generative design uses algorithms to generate design alternatives and optimise decisions based on specified design goals.

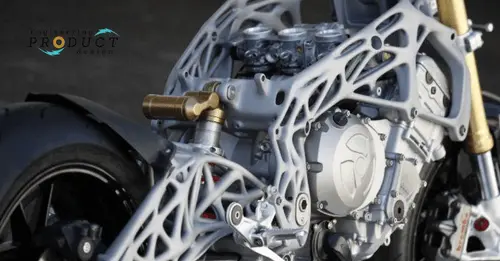

Generative design 3d printing

Generative design and 3D printing are two technologies that can be combined to create new and innovative products.

In generative design, artificial intelligence, machine learning, and simulation generate various design alternatives based on specified design goals and constraints. The process involves defining design goals, constraints, and parameters and allowing the computer to create and evaluate multiple design options.

3D printing is a process that creates physical objects by building up material layer by layer. It can develop products, including complex geometries, integrated functional elements, and custom shapes.

The generative design combined with 3D printing offers several benefits, including:

- Faster product development: Generative design and 3D printing can reduce the time required for product development, as designs can be generated and prototypes produced quickly.

- Improved design optimisation: Generative design algorithms can be used to optimise designs for specific performance criteria, such as strength, weight, stiffness, or manufacturing costs, and 3D printing can be used to produce prototypes and final products quickly.

- Lower costs: By reducing the need for manual design and prototyping, combining generative design and 3D printing can lower costs and increase efficiency.

- Increased design freedom: Generative design algorithms can generate designs that may have yet to be considered by human designers, and 3D printing can be used to produce complex shapes and geometries that would be impossible to manufacture using traditional manufacturing methods.

Overall, generative design and 3D printing can create new and innovative products that meet specific design goals and performance criteria.

Generative design tools

Generative design uses artificial intelligence, machine learning, and simulation to generate various design alternatives based on specified design goals and constraints. There are several tools available for generative design, including:

- SolidWorks: SolidWorks is a popular computer-aided design (CAD) software with generative design capabilities. It can generate, evaluate, and refine design options based on specified design goals and constraints.

- Autodesk Fusion 360: Autodesk Fusion 360 is a comprehensive product design and engineering software with generative design capabilities. It can generate, evaluate, and refine design options based on specified design goals and constraints.

- Onshape: Onshape is a cloud-based product design platform with generative design capabilities. It can generate, evaluate, and refine design options based on specified design goals and constraints.

- Ansys Discovery: Ansys Discovery is a simulation-driven generative design software that can generate, evaluate, and optimise designs based on specified design goals and constraints.

- Granta Design CES: Granta Design CES is a materials information management software with generative design capabilities. It can generate and evaluate design alternatives based on materials data and specified design goals.

- Creo Generative Design: Creo Generative Design is a product design tool developed by PTC (Parametric Technology Corporation) that leverages advanced algorithms to automate the design process and help users quickly generate and evaluate design alternatives

- nTop Platform from nTopology: nTop Platform is a cutting-edge software solution developed by nTopology. It provides a unique combination of 3D modelling, simulation, and optimisation capabilities in one Platform, making it a versatile tool for a range of design and engineering applications

- NX from Siemens: NX is a comprehensive software solution developed by Siemens that includes tools for generative design. The generative design tools in NX use artificial intelligence and machine learning to analyse design requirements and generate optimised solutions that meet performance, manufacturing, and other constraints.

These are some of the most commonly used generative design tools. However, many other tools offer different features and capabilities, so the best tool for a specific project will depend on the specific design goals, constraints, and requirements.