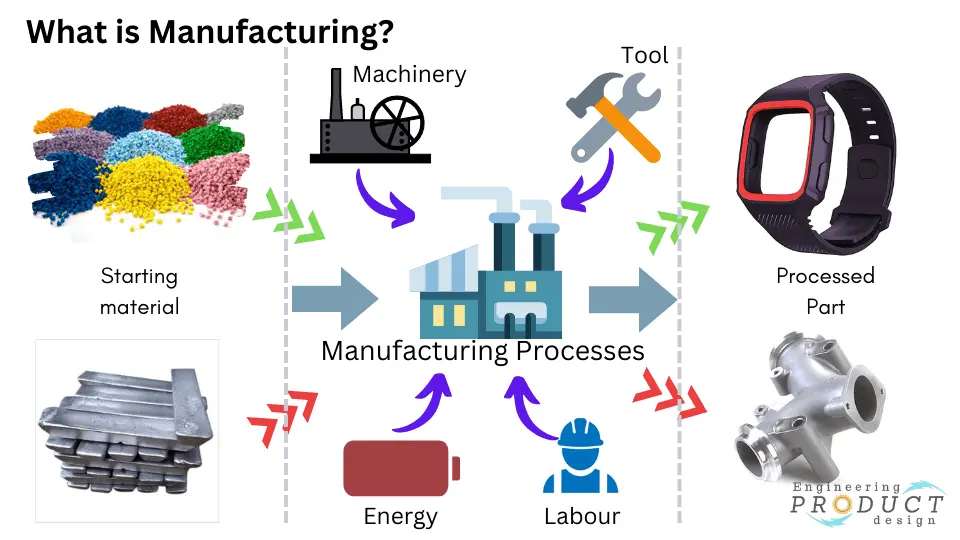

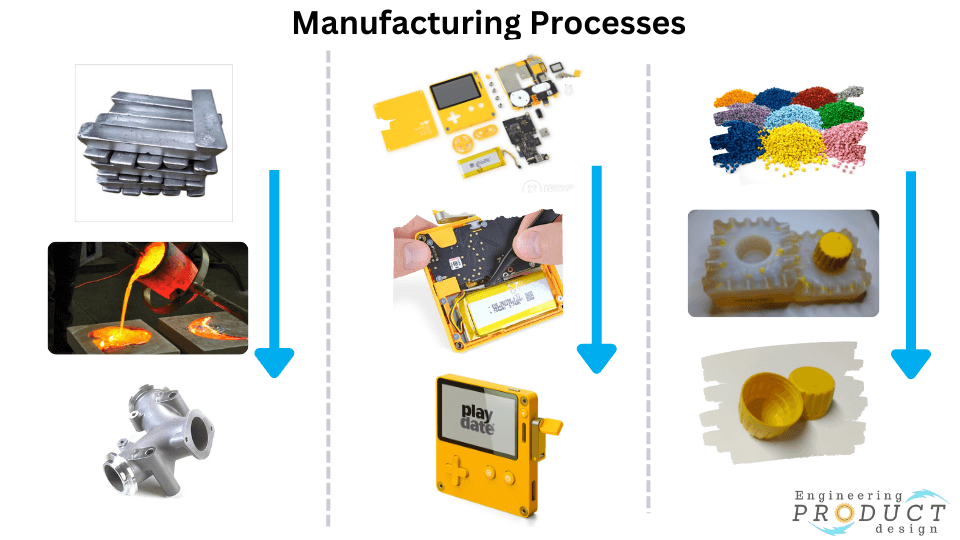

Manufacturing is the production of goods from raw materials using energy, labour, machinery, tools, and manufacturing processes. Manufacturing uses manufacturing processes to change the geometry, characteristics, and appearance to create products.

Contents covered in this article

What is Manufacturing?

Manufacturing is a large-scale production of goods using energy, manual labour, machinery, tools, and manufacturing processes to convert raw materials, parts, and components into finished items by changing geometry, properties, and appearance.

Modern-day engineering products are complex and comprise various material combinations, electronics control boards, wires, batteries and charging ports. Hence, modern-day manufacturing also includes assembling these elements to create the finished product.

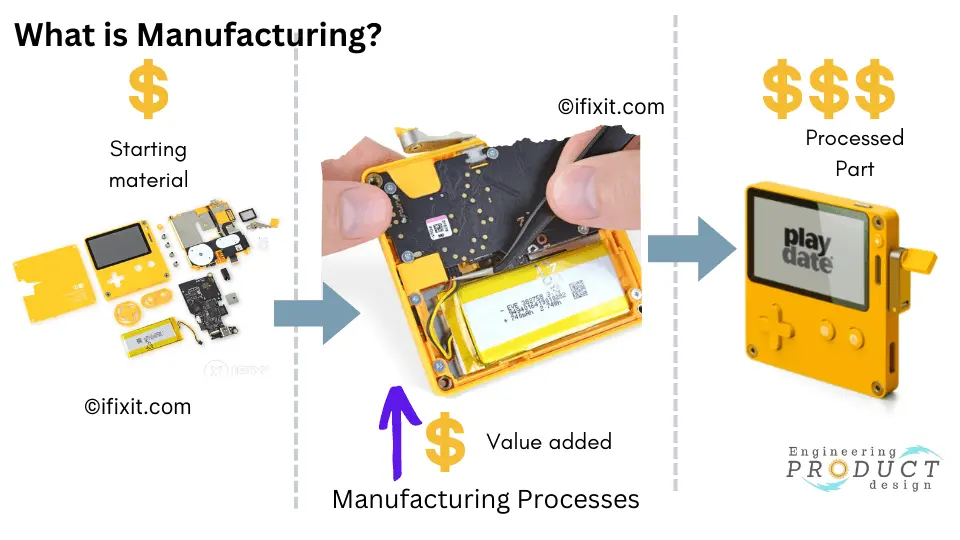

Economically, manufacturing can be defined as the economic transformation of materials into items of better value through one or more processing and assembly operations. The critical point is that production adds value to a starting material or element by changing its form, fit and function to satisfy end users’ requirements.

Manufacturing types

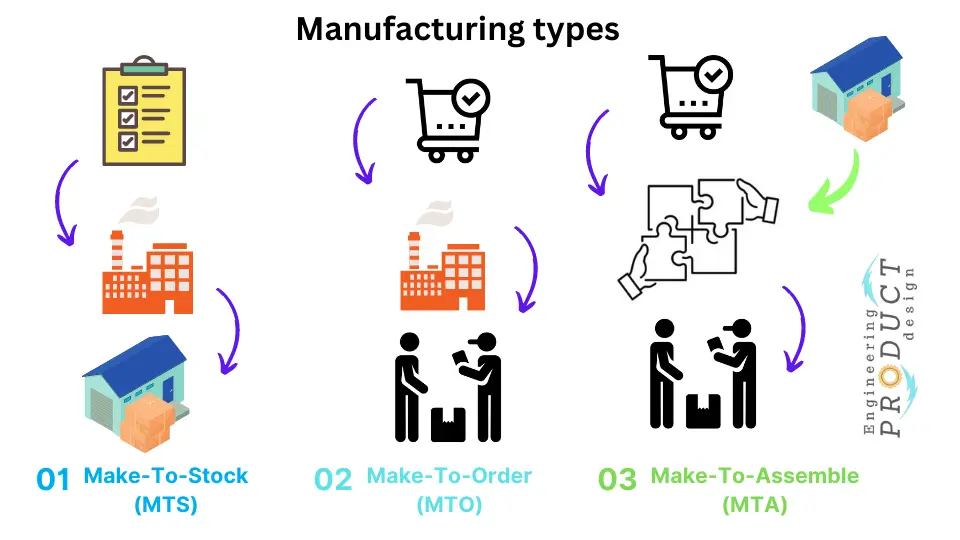

There are three main manufacturing types in how businesses produce products. They are Make-to-Stock (MTS), Make-to-Order (MTO), and Make-to-Assemble (MTA).

Make-To-Stock (MTS)

Make-to-stock is a traditional strategy that businesses use to match inventory to expected consumer demand. For example, a company would estimate consumer demand for the product and produce to stock them to meet the estimated demand.

Make-To-Order (MTO)

Make-to-order, sometimes called made-to-order, is a manufacturing strategy that generally begins only after the consumer purchases the product. MTO benefits include customer customisation, reduced stock obsolescence, reduced finished goods inventory, and reduced overall waste.

Make-To-Assemble (MTA)

Make-to-assemble, also called assemble-to-order, is a business strategy in which products are quickly produced from stocked parts only when an order is confirmed. MTA is a hybrid of make-to-order and make-to-stock methods.

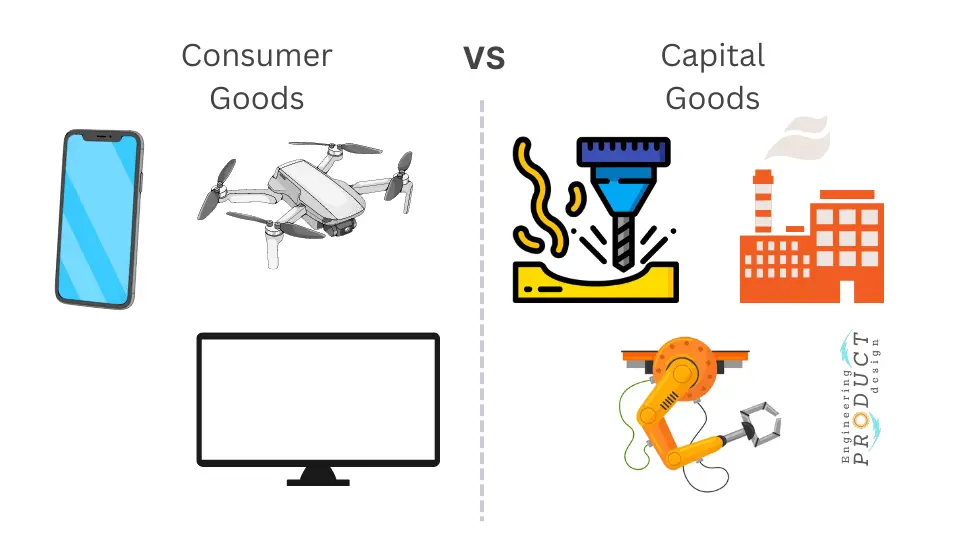

Manufactured product types

Products fall into Consumer and Capital goods. As the name suggests, consumer goods are products manufactured to sell directly to the customer, such as Smartphones, TVs, Drones and Laptops.

Capital goods are items companies and businesses purchase to make products for consumers or other capital goods such as CNC machines, Injection moulding machines, and Factory equipment.

This article details Capital goods in more in-depth.

What are Manufacturing Processes?

Manufacturing processes are used in large-scale manufacturing to create value-added engineering products and components using physical and chemical processes to change a starting material’s geometry, characteristics, and appearance.

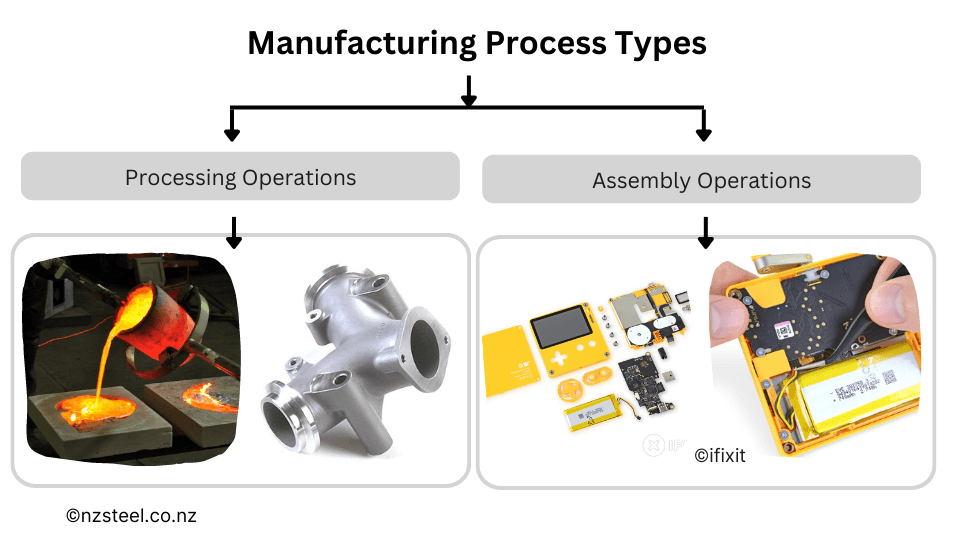

Manufacturers typically carry out the manufacturing processes as a unit operation, which means it is a single step in a series of steps required to transform a starting material into a finished product. Processing operations and assembly operations are the two basic types of manufacturing operations.

Types of Manufacturing processes

Manufacturing processes encompass a wide range of activities crucial for creating products. These processes can be broadly categorised into two primary types:

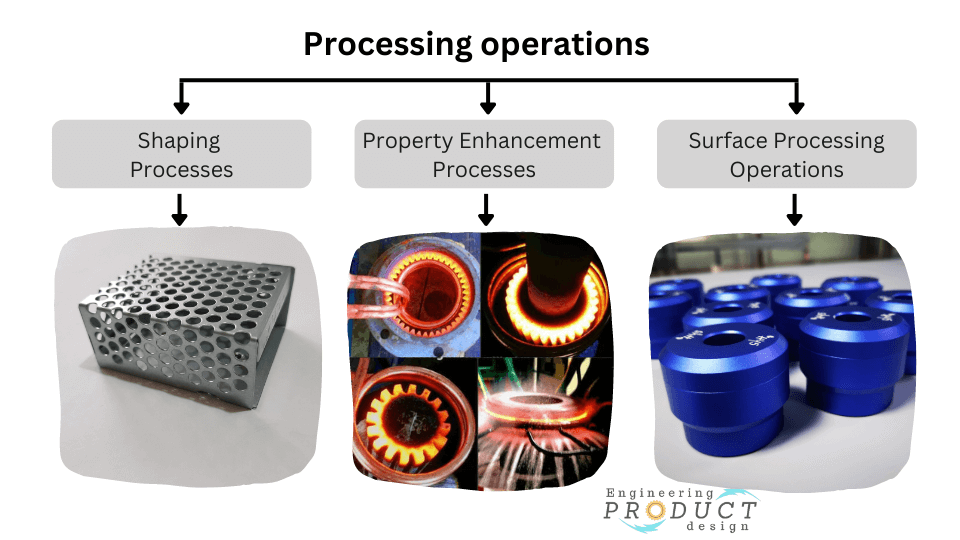

Processing operations – Manufacturing Processes

Processing operations add value by transforming a part from one state to another by changing its shape, property, appearance and surface texture with energy. Energy can take the form of mechanical, thermal, electrical and chemical. For example, milling an aluminium billet to achieve the required part or anodising a milled aluminium part would be a processing operation.

Although processing operations are primarily performed on distinct components, sometimes assembled parts, such as welded sheet metal fabrication, need processing like powder coating. Also, near-net shaping processing, such as sand casting or investment casting, would require some machining for features like threads, o-ring grooves, and bearing bores.

These Processing operations can be broadly categorised into three primary types:

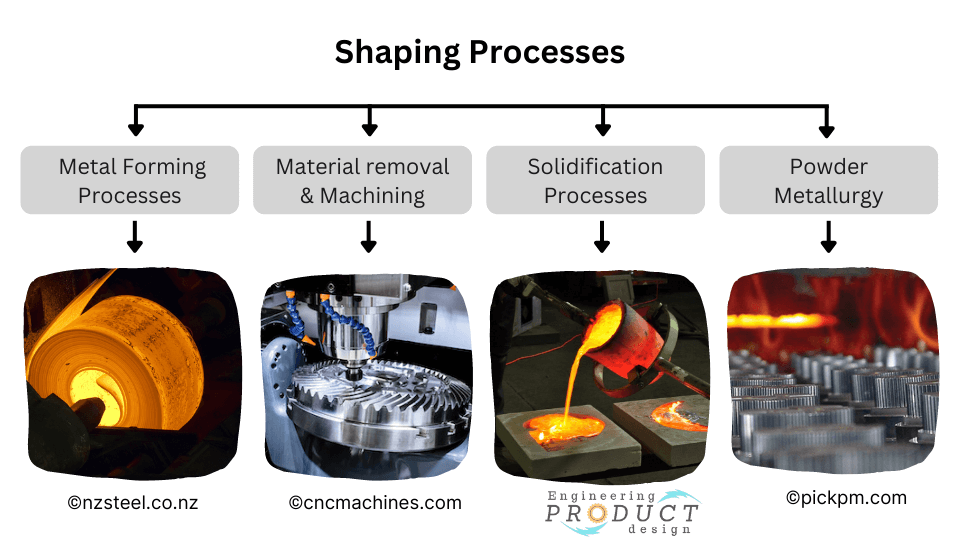

Shaping Processes

As the name suggests, this alters the geometry of the workpiece by primarily applying heat, mechanical force or a combination of both. As the image below shows, Shaping processes can be divided into the following four categories:

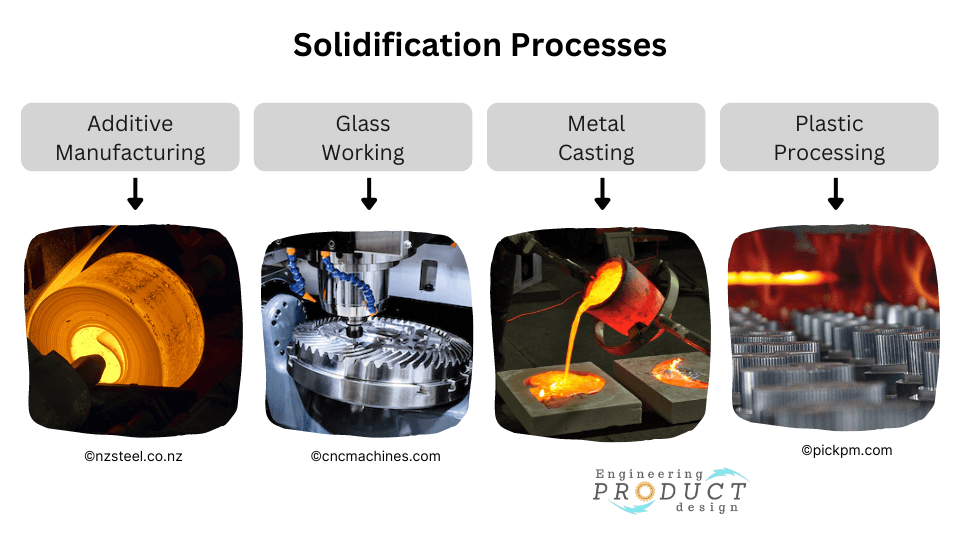

Solidification processes

Manufacturer melts raw materials such as plastic pellets, metal or quartz sand to transform them into semi-fluid or liquid. This melted material then cools down and solidifies to form a 3d shape. This process can be used to process almost all materials from metal, plastic, ceramic, and Glass. Once they are in a liquid state, they can be pushed or poured into a mould. The new AM technology also falls into this category, where the material is heated and added layer by layer to create a 3D object.

Solidification processes can be grouped into the following four categories:

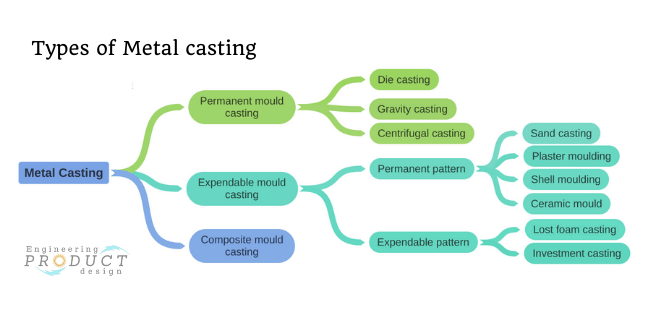

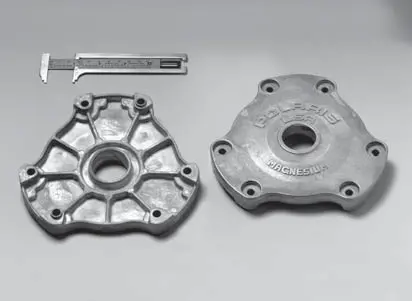

Metal casting

Metal casting is a process where the molten metal is fed into a mould by gravity or force, solidifying it into the mould shape part called “casting”. Numerous shape-casting methods are available, such as Sand casting, Die casting and Investment casting, making it one of the most versatile manufacturing processes. Casting can produce complex part geometries with both external and internal shapes.

Die casting, Gravity casting, Centrifugal casting, Sand casting, Shell moulding, Plaster mould, ceramic mould, investment casting, and lost foam casting are some of the metal casting processes.

Detailed articles on Metal castings

- Complete guide to Metal casting

- What are Sand casting and its applications

- Introduction to Centrifugal casting

- Investment casting guide

- Difference Between Sand Casting, Die Casting And Investment Casting

Glass working

Glass is processed by melting and shaping it, either in moulds or by blowing. They are commercially manufactured in an almost unlimited variety of shapes, such as flat sheets, plates, rods, tubing, bottles, vases, eyeglasses and glass fibres.

Guide to the glass production process

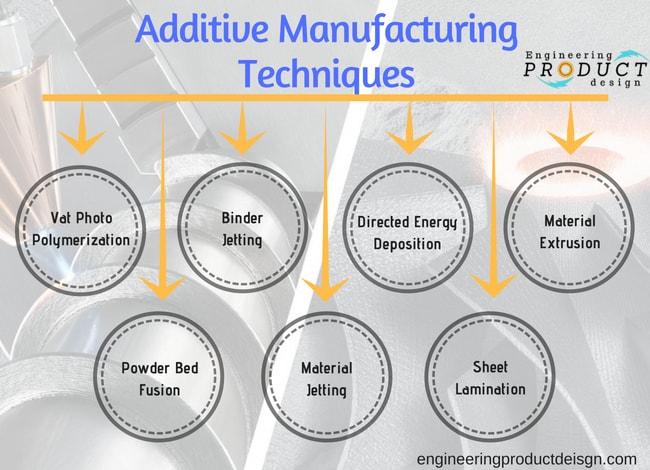

Additive manufacturing processes

The fundamental principle of Additive Manufacturing technology is that it directly uses CAD-generated 3D models to fabricate a three-dimensional object by adding layer upon layer of material and fusing them. These are also known as 3D printing technologies.

Vat photopolymerisation, Material Extrusion, Material Jetting, Binder Jetting, Powder bed fusion, directed energy deposition, and Sheet lamination are the seven main additive manufacturing technologies. The table lists some of the most common types and subtypes below.

| Main AM Category | Technology types |

|---|---|

| Vat photopolymerisation | Stereolithography (SLA), Direct Light Processing (DLP), Continuous Direct Light Processing (CDLP) |

| Material Extrusion | Fused deposition modelling (FDM) |

| Material Jetting | PolyJet technology, NanoParticle Jetting (NPJ), Drop-On Demand (DOD) |

| Binder Jetting | Binder Jetting |

| Powder bed fusion | Selective Laser Sintering (SLS), Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS) |

| Directed energy deposition | Laser-based DED, Electron beam-based DED, Plasma or Electric arc-based DED |

| Sheet lamination | Laminated Object Manufacturing (LOM), Composite Based Additive Manufacturing (CBAM) |

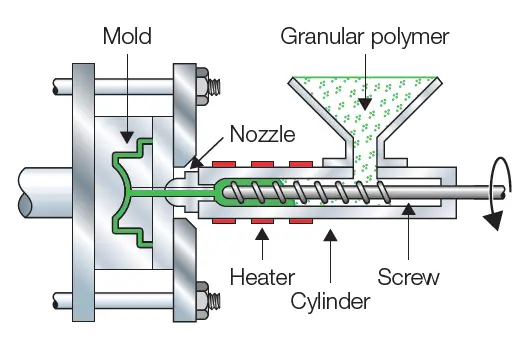

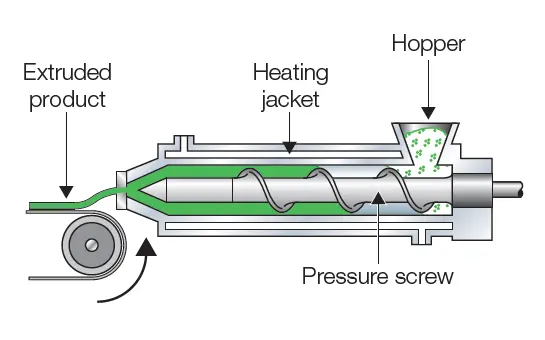

Plastic processing

Plastic processing converts raw materials of plastics into finished products by forming them into desired shapes. These bulk plastics are available in resin, granules, pellets, powders, sheets, preforms, or fluids. In addition, plastic materials can contain various additives, impacting their properties and processability.

Following initial types of plastic processing, the plastic part may be subjected to various processes such as welding, adhesive bonding, machining, and surface decoration.

| Plastic Processing types | Description |

| Injection Moulding | Melts and injects polymer into a mould cavity to form complex shapes upon cooling. |

| Reaction injection moulding | Mixes reactive liquid components, which polymerise and form a part inside the mould. |

| Liquid Injection Moulding | Injects liquid silicone rubber into a mould, curing it into precise parts through heat. |

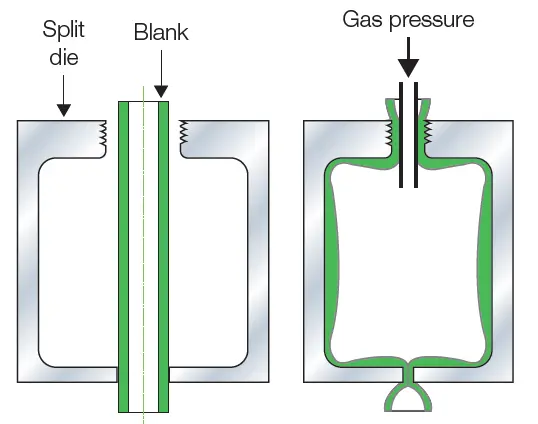

| Blow moulding | Inflates heated plastic into a mould cavity to create hollow parts like bottles. |

| Polymer Extrusion | Forces melted polymer through a shaped die to form continuous profiles or sheets. |

| Compression Moulding | Presses heated polymer into a mould using high pressure to shape and solidify. |

| Transfer Moulding | Transfers pre-heated polymer into a closed mould cavity for intricate designs. |

| Thermoforming | Heats plastic sheets until pliable and then moulds them over a form to create shapes. Vacuum and Pressure forming are the two main types of Thermoforming. |

Particulate processing – Powder metallurgy

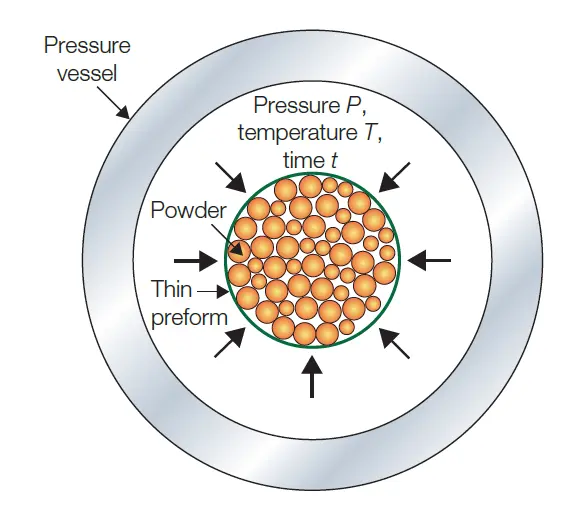

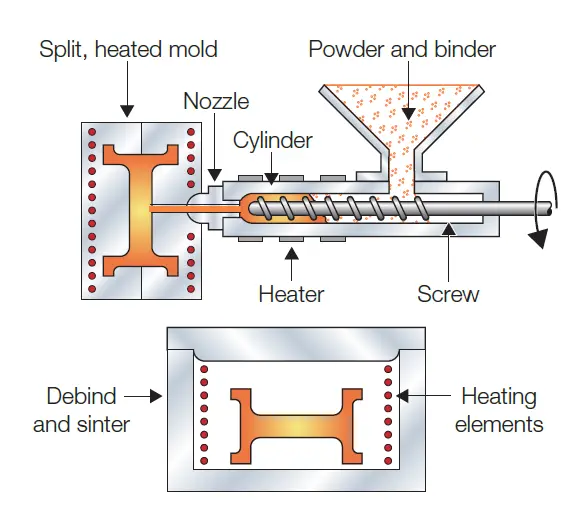

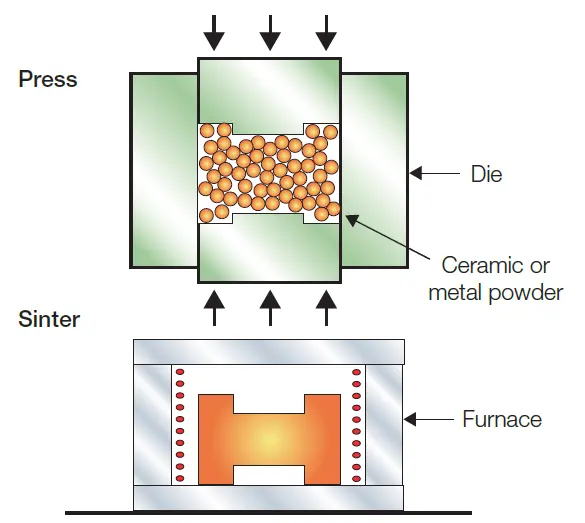

Powder metallurgy is a method of metal solidification that involves heating compacted metal powders to temperatures just below their melting points to create complex rigid 3D components.

Metal or ceramic powders serve as starting materials. Although these two materials differ significantly, particle processing techniques used to shape them are very similar.

Some of the widely used Powder metallurgy processing techniques are Press & Sinter process, Isostatic pressing, Hot Isostatic Pressing (HIP), Powder Injection Moulding (PIM), and Metal Injection moulding (MIM).

| Process | Description |

| Press & Sinter Process | Press & Sinter process compacts metal or ceramic powder into a shape and then sinters it at high temperatures to bond particles. |

| Cold Isostatic Pressing (CIP) | CIP applies uniform pressure to powder within a flexible mould submerged in a fluid, forming dense, isotropic parts. |

| Hot Isostatic Pressing (HIP) | HIP combines high pressure and elevated temperature to densify powders, consolidate castings, and improve properties. |

| Powder Injection Molding (PIM) | PIM injects powder-binder mixture into a mould, debinds it, and sinters it to produce high-precision parts. |

| Metal Injection Moulding (MIM) | MIM uses metal powder mixed with a binder and injects it into moulds; the part is then debound and sintered for precision components. |

| Powder Rolling | Powder Rolling compresses and elongates powder into sheets or strips by passing through rolling mills at elevated temperatures. |

| Powder Extrusion | Extrusion forces powder through a die at high temperatures to create long shapes or profiles, followed by sintering. |

| Powder Forging | Power forging presses powder into a shape and then forges it while heated to improve density and mechanical properties. |

| Hot Pressing | Hot pressing compacts powder in a mould while applying heat, resulting in dense, solid parts. |

| Spark Sintering | Spark sintering uses a pulsed electric current and pressure to rapidly sinter powder, enhancing properties and reducing processing time. |

Metal Forming

Metal forming, sometimes known as the Deformation process, refers to a broad range of manufacturing processes that use plastic deformation to alter the shape of a malleable metal to create the required form. The material must be sufficiently ductile to prevent fracture during deformation, and the manufacturer uses forces larger than the material’s yield strength to mould and deform the workpiece.

There are two types of Metal forming

- Bulk deformation

- Sheet metalworking or Sheet metal forming

Bulk deformation

Bulk deformation processes are typically characterised by significant deformations and massive shape changes, with a relatively small surface area-to-volume ratio. The term bulk refers to work parts with a low area-to-volume ratio. Cylindrical billets and rectangular bars are common starting work shapes for these processes. Manufacturers heat the material before forming to a temperature below the melting point to promote ductility.

Metal Rolling, Metal forging, Metal extrusion, and drawing are the four basic types of bulk deformation processes.

Detailed articles on Metal forming techniques

- Complete guide to Metal forming

- What are Metal extrusion and its applications

- Introduction to Metal forging

Sheet metalworking

Sheet metalworking, also known as sheet metal forming, is the cutting and forming of relatively thin metal sheets, strips, and coils. Bending, sheet metal drawing, and shearing are the three basic types of Sheet metalworking processes.

Sheet metalworking processes are classified into three categories: bending, sheet metal drawing, and shearing.

- Shearing or Cutting

- Bending

- Drawing

Complete guide to Sheet Metal forming

Material removal process

As the name suggests, the material removal process removes material or surface modifications to achieve the desired feature, shape and size. They are a family of shaping operations commonly called machining operations. CNC machining is the most common and used extensively to machine metal such as Stainnless steel and Aluminium alloys.

Near-net or net-shape parts produced by metal casting, forming, and shaping processes frequently necessitate additional machining operations before the product is ready for use.

Machining processes are classified into three main categories:

- Conventional machining – CNC machining

- Turning

- Drilling

- Milling

- Abrasive processes

- Grinding

- Advanced machining processes

- Electrical Discharge Machining (EDM)

- Electrochemical machining

- Thermal energy processes

- Chemical machining

- Plasma cutting

- Laser cutting or Laser Beam Machining

- Hydrodynamics – Water cutting machining

Typical parts in a car manufactured using machining operations are Threaded fasteners, door locks, threaded holes, keys, engine block and crankshaft.

Property enhancing processes – Heat treatment

Heat treating is a sequence of treatments that use heat to change a metal’s or alloy’s properties. These treatments are used for various reasons, the most important of which is to control mechanical properties such as hardness, ductility, strength, toughness, and internal stresses.

Heat treatment processes are divided into three categories: Hardening, annealing, and surface hardening

Surface Processing operations

Cleaning, surface treatments, coating and deposition processes are surface processing operations.

Cleaning involves Chemical and mechanical operations to remove surface contaminants such as dirt, oil and rust from the surface.

Surface treatments are mechanical and physical operations that change the surface of a part in some way, such as improving the finish or impregnating it with atoms of foreign material to alter its chemistry and physical properties. Processes such as sandblasting, aqua blasting, and shot peening falls into this category.

Coating and thin film deposition processes apply a material coating to the work part’s exterior surface. Electroplating, aluminium anodising, painting, and porcelain enamelling are all common coating processes.

Physical and chemical vapour deposition creates fragile coatings of various substances.

Assembly operations – Manufacturing Processes

The second primary manufacturing process is assembly operations. Assembly operations involve joining two or more components to create a new entity called an assembly using permanent joining processes like welding and binding and Mechanical fastening using screws and rivets.

For example, the assembly could use self-tapping screws to hold the plastic housings together and adhesive to hold the lenses for the VR headset.

Assemblies could be either fully mechanical entities such as a gearbox and mechanical power transmission units or electro-mechanical assemblies such as a VR headset.

The assembly components are permanently or semi-permanently connected using permanent joining processes or mechanical fastening.

Permanent joining process

Adhesive bonding, welding, soldering, and brazing are permanent joining processes. They connect components that cannot be easily disconnected.

Welding

Welding is a manufacturing process in which two components are fused using heat, pressure, or both to form a joint as the parts cool. This manufacturing process is typically performed on metals and thermoplastics. The finished welded joint is known as a weldment.

Brazing and Soldering

Brazing and soldering are the same: they melt the filler metal but not the base materials. Through capillary action, the liquid filler metal wets the base materials. When the liquid filler metal solidifies, it bonds to the base materials, forming a joint.

Adhesive bonding

Adhesive bonding is joining two surfaces together, typically by forming a smooth bond. Bonding may entail using glue, epoxy, or one of a variety of plastic agents that bond via solvent evaporation or curing via heat, time, or pressure.

Mechanical fastening

Mechanical fastening is the most common way for many materials to be joined in the industry and can connect two or more parts in a joint that can be easily disassembled. Initially used for metal joining, it is now widely used to join metals, plastics, and other materials. Permanent and nonpermanent industrial fasteners are the two main types and can be grouped into the following groups.

- Threaded fastening

- Permanent fastening method

Threaded fastening in this category includes screws, bolts, and other threaded fasteners. Other mechanical assembly techniques, such as rivets, press fitting, and expansion fits, create a more permanent connection, falling under the Permanent fastening method.

Production vs Manufacturing

The words manufacturing and production are often used interchangeably in the industry. Manufacturing converts raw materials into finished goods using machinery, tools and human resources. On the other hand, production refers to the processes or methods that convert inputs, such as raw materials and semi-finished components, into products and services, which may or may not involve using tools, machinery and human resources.

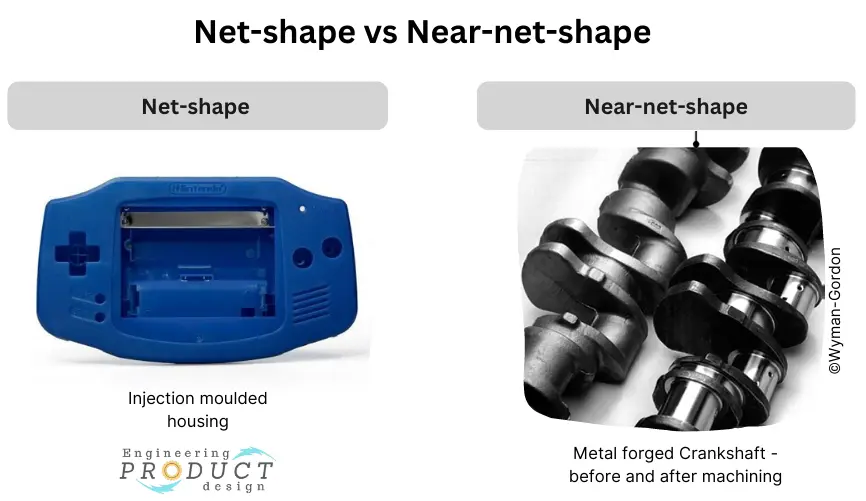

Net-shape and Near-net-shape

Net-shape and near-net-shape manufacturing are methods for producing a part in a single operation with the final specified dimensions, tolerances, and surface finish. For example, a cast, forged gear, or crankshaft typically lacks the required dimensional properties, necessitating extra processing such as machining or grinding. These additional activities can dramatically increase the cost of a product.

What is Near-net-shape manufacturing?

Near net shape (NNS) refers to manufacturing processes that convert raw material into a component that is as close to the finished product as possible in size and shape. Depending on the part design and features, processes like Sand casting, die casting, and investment casting can be examples of Near net shape as they might need features like threads and bearing surfaces machined after the initial process.

What is Net-shape manufacturing?

Net shape processes are primary processes that convert raw material into parts with no subsequent machining or different techniques required to achieve the final shape and size. An Injection moulding part is an example of a Net-shape manufactured part.

Precision casting, forging, shaping sheet metal, vacuum casting, powder metallurgy, additive manufacturing and injection moulding of metal powders, and injection moulding of polymers are typical instances of net-shape production.

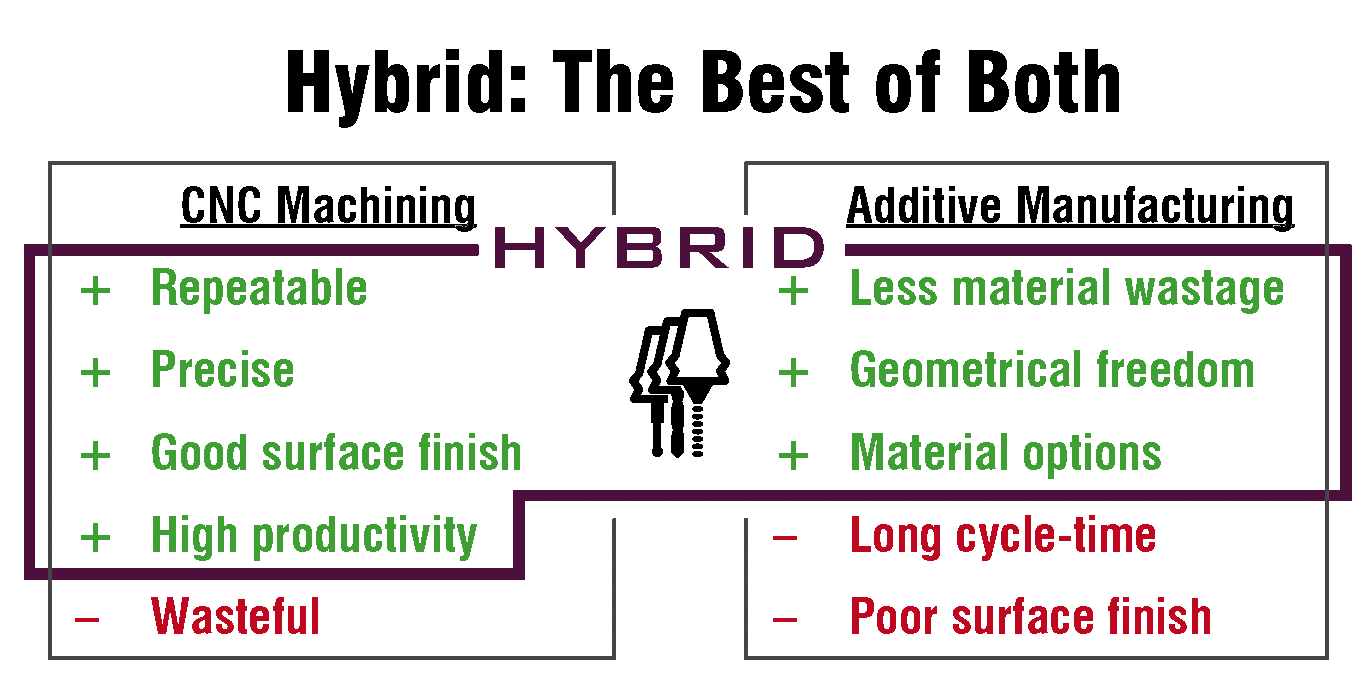

What is Hybrid Manufacturing?

It is a manufacturing process where additive manufacturing and conventional subtractive manufacturing technologies are combined and used together within a single setup to create a part.

Using different manufacturing systems to create a single part is not new for the design and manufacturing industry. For example, machine threads, O-ring grooves & mating flat surfaces are machined regularly on sand castings. These are, however, post-processing i.e., different set up on a milling machine after the casting has been done.

Contrastingly, Hybrid manufacturing machines such as DMG Moris’ Lasertec 65, combines one of the 7 types of Additive Manufacturing (AM) technologies and CNC milling capabilities into one single machine bed. This allows both technologies to work on the part one after another or alternatingly to create geometry and desired features. For example, AM technology with its freedom creates a complex shape while the CNC milling head carries out the precision machining.

Why do we need hybrid manufacturing?

Every manufacturing process will have its own advantages and disadvantages and is only be suited for certain applications and materials. Although Additive manufacturing or 3D printing has come a long way from its inception, it still has limits such as limited material options and most notably lack of manufacturing tolerance, poor surface finish, post-machining requirement etc.

Video credit:DMG mori

CNC milling, turning etc., is the conventional way of achieving that finer tolerance but lacks the flexibility when challenged with complicated geometries.

So, combining AM and the conventional subtractive method will bridge the gap by eliminating the negatives of the two methods enabling the user to have the best of both worlds(illustrated by the infographic in figure below).

When combining AM and CNC machining, not all 7 types of additive manufacturing technologies will be suitable. Currently, considering how the DED technology works, it lends itself nicely to hybrid systems. But, few companies have successfully managed to combine other types of AM technologies into their hybrid offering.

Types of Hybrid manufacturing technologies

Out of 7 AM technologies, currently, the following four types of AM techniques are used in various forms with CNC machining.

- Laser metal deposition

- Metal powder application

- Sheet lamination

- Powder bed fusion

Hybrid manufacturing companies

Companies like DMG Mori, Hybrid manufacturing technologies, Optomec, 3D Hybrid are a few companies that have excelled in this space.

- Optomec – Direct energy deposition technology

- DMG Mori – Direct energy deposition technology

- Mazak – Direct energy deposition technology

- Hybrid Manufacturing Technologies – Direct energy deposition technology

- 3D-Hybrid – Direct energy deposition technology

- Matsuura – Powder bed fusion technology

- Hermle – Metal powder application technology

- Sodick – Powder bed fusion technology

- Fabrisonic – Sheet lamination technology

References and recommended reading

- Beeley, P. (2001). Foundry Technology (Second edition ed.). Oxford: Butterworth Heinemann.

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth Edition ed.). London: Pearson.

- Groover, Mikell P.(2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems (Forth edition ed.). Hoboken, NJ: J. Wiley & Sons, 2010.

- Ashby, M.F., 2005. Material Selection in Mechanical Design. 3rd ed. Oxford: Butterworth-Heinemann.