A Microphone sensor helps an electronic product capture sound waves and convert that energy into electrical energy so it can be processed and used in applications such as voice recognition in smart speakers, mobile phones and smartwatches.

What is a microphone?

A Microphone sensor helps an electronic product capture sound waves to process. Microphones are transducers which convert sound energy into electrical energy. Morden day consumer portable electronic devices such as tablets, smartwatches, mobile phones, earbuds, Headphones and laptops widely uses board-level microphone sensors for various reasons.

A prime example is Amazon’s echo dot which uses seven microphones to listen to every word you utter to analyze and understand. Most of the earbuds and Headphones use multiple microphones for Active Noise Cancellation. This article explores in depth only board-level microphone sensors used in consumer electronics.

Microphone applications

MEMS and other board-level microphone sensors find their application in various consumer, commercial, and industrial products.

- Portable consumer devices such as Smartphones, Tablets, Smartwatches, Smart home assistants, Televisions and remotes

- Audio processing equipment

- Used for Active noise cancellation in Earbuds and Headphones

- Wireless sensor networks

- Hearing aids

- Biomedical instruments

- Industrial sensors in the field of predictive maintenance

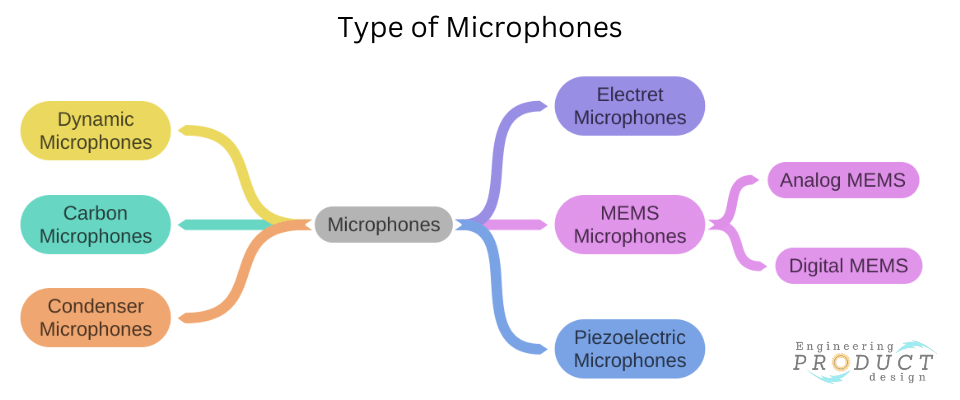

Microphone sensor types

Microphone technology is very advanced in terms of board-level sensors. They range from simple and popular condenser microphones to cutting-edge mems solutions with internal amplifiers and other electronic processing functionality.

Dynamic, Carbon and Condenser microphones are not board-level sensors, whereas MEMS, ECM and Piezomicrophones are used in PCBs due to their miniature construction. Therefore, this article explores only board-level microphone sensors used in consumer electronics.

| MEMS microphones | Dynamic microphones |

| Electret microphones ECM | Carbon microphones |

| Piezoelectric microphones | Condenser microphones |

MEMS microphone

A MEMS microphone is an electro-acoustic transducer that combines a sensor (MEMS) and an application-specific integrated circuit (ASIC) into a single package. The sensor converts the sound pressure to capacitance change, and ASIC manages the MEMS polarization and the two outputs – Analogue & Digital.

In recent years, MEMS technology has revolutionized the sensor manufacturing industry. MEMS is an abbreviation for microelectromechanical systems. As the name suggests, very small-sized electromechanical systems are integrated into IC chips. This technology reduces the sensor size dramatically and enhances accuracy and performance manifold. Different types of MEMS sensors have been developed for measuring various physical quantities.

Advantages and disadvantages of MEMS

Advantages

- Withstands high temperature and shock

- Suitable for reflow soldering

- Better noise performance compared to ECM

- operating temperature range of -40oC to +85oC

- flat wideband frequency response

- omnidirectional

- Several high-performance modes

- Low power consumption

- Small form factor

Disadvantages

- Comparably more expensive

- Complex design requirement

How does a MEMS Microphone work?

MEMS microphone contains both electronic and mechanical components on the same semiconductor wafer. It has a transducer and an application-specific integrated circuit (ASIC) integrated into a single component protected by a mechanical cover. A small hole on the cover or the base PCB allows the sound into the microphone. It is either top-ported or bottom-ported, depending on whether the hole is in the top cover or the PCB.

The image below shows that it consists of a micro-sized pressure-sensitive diaphragm transducer and signals conditioning pre-amplifier circuitry. In addition, the Digital version of the MEMS sensor has a digital converter to convert the analogue signal to a digital signal.

- The micro-sized pressure-sensitive diaphragm acts as a single plate of a capacitor. The ASIC-based charge pump circuit injects charge between the capacitor plates.

- The diaphragm movement due to sound pressure changes the capacitance, which in turn causes the generation of an electrical signal. This electrical audio signal is then fed to the pre-amplifier.

- An impedance converter reduces the output impedance of the signal to something usable before feeding into the amplifier.

Analogue versus digital MEMS microphones

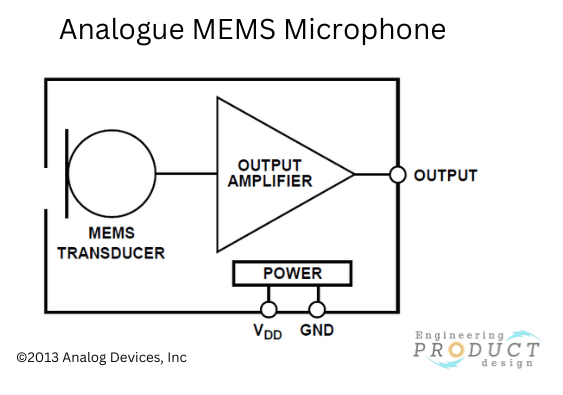

The main difference between analogue and digital microphone sensors is the non-existence of an Analog-to-Digital Converter (ADC). Instead, the analogue output signal is obtained from the pre-amplifier and directly fed to an amplifier in analogue microphones. Due to the absence of ADC, analogue sensors exhibit better power consumption. Therefore, these microphones are suitable for simple applications such as loudspeakers and radio communication.

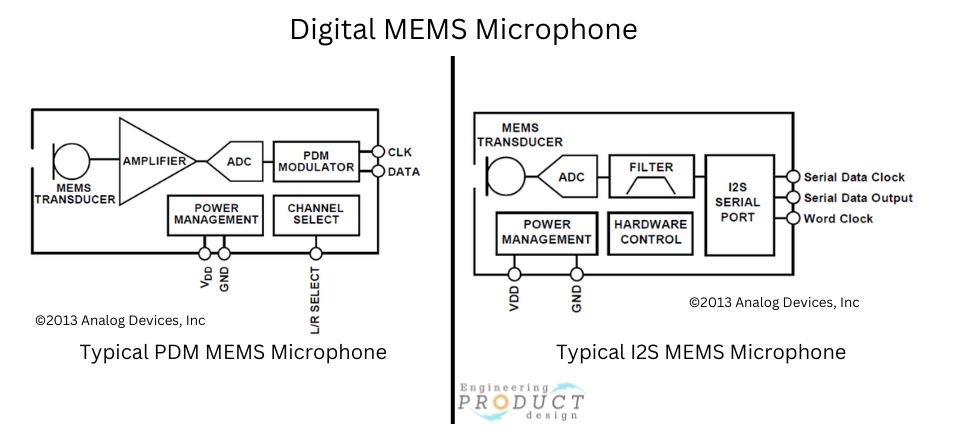

Digital MEMS microphones commonly use the PDM (pulse density modulation) format for digital encoding. The PDM encoding format requires only one clock and one data line. Some MEMS microphones also have digital I2S outputs processed by an internal decimation filter. Digital systems offer many advantages over analogue systems, such as low cost, low complexity, higher noise immunity, and faster processing.

Digital MEMS microphones

The digital output from the ADC can be in two possible formats: Pulse Density Modulated (PDM) or I2S. PDM microphones only require a single clock and data line. I2S microphones feature the additional stages of decimation filter and serial port.

Digital microphone with PDM is the most common interface, and the images below show simplified block diagrams of PDM and I2S digital microphones.

Aside from having a smaller footprint, lower power requirements, and better electrical noise rejection, one of the main advantages of MEMS microphones is that they have more output options, giving designers and engineers more flexibility.

Analog MEMS microphone

This circuit, shown in the image below, is essentially an amplifier with a specific output impedance for an analogue MEMS microphone.

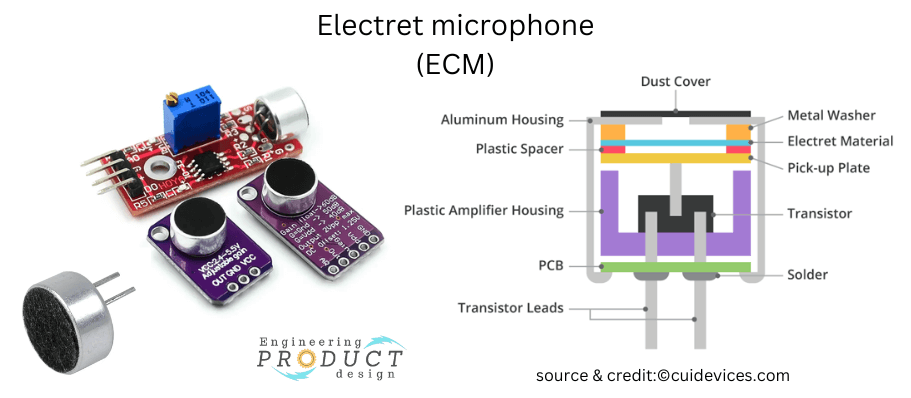

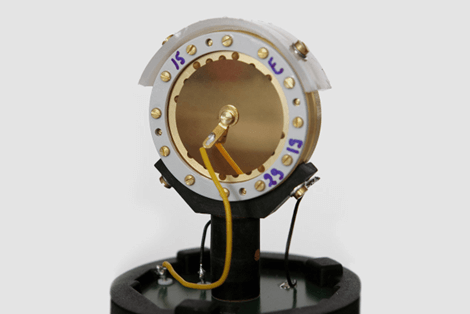

Electret microphone (ECM)

ECM uses electrostatic and magnetic properties to function with an electret diaphragm that acts as a single capacitor plate. The variation in diaphragm position leads to the variation in capacitance. Hence, a varying electrical signal is obtained across the capacitor. Then this weak electrical signal feeds into a common-source JFET amplifier which amplifies the signal and blocks DC components.

ECMs are particularly useful in dusty and humid environments. Because of their rugged construction and higher ingress protection (IP) rating, product designers use them in home assistants, voice recognition, hearing aids and industrial applications.

Advantages and disadvantages of ECM

Advantages

- Relatively low cost

- Available in a range of sizes

- Output via a low-noise JFET buffer

- They are available with solder pads, pins, surface mount and wire lead.

- operating temperature range of -20oC to +70oC

Disadvantages

- ECM is unsuitable for the high temperatures involved with the reflow soldering process as it affects the diaphragm.

- The performance, repeatability, and stability of ECMs over temperature and other environmental conditions are poor.

Piezoelectric microphones

Piezoelectric microphones are known as contact microphones, and crystal microphones use the piezoelectric effect to convert sound waves to electrical signals. These piezoelectric sensors can detect ultrasonic waves and have a frequency range of several megahertz.

Crystal microphones were commonly used in telephone handsets and incorporated into public address systems during their early years. The main disadvantages of piezoelectric microphones are high impedance and poor linearity.

Dynamic microphones

Dynamic microphones use electromagnetism to convert sound into an electrical signal. They fall under two types, Moving coil and ribbon microphones. Because of their rugged construction, Dynamic microphones are widely used for stage use.

Read more about it here.

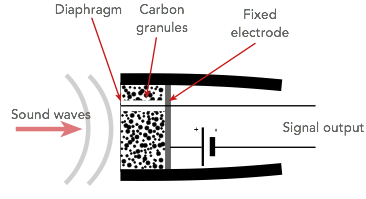

Carbon microphones

Carbon microphones contain carbon granules. Its property changes the resistance across the granules in proportion to the pressure applied. Hence, they can function as a transducer, converting sound into an electrical signal as alternating sound waves change the resistance by varying the compressive force.

Read more about carbon microphones here.

Condenser microphones

A condenser microphone consists of a pair of charged plates that can move closer or further apart due to variations in air pressure caused by sound waves. In effect, the plates function as a sound-sensitive capacitor.

Read more about it here.

Characteristics for MEMS microphone selection

Selecting appropriate components is an essential step in designing electronic circuits. However, inappropriate selection of parts can lead to performance issues and even burn-outs in extreme cases. The same is the case with MEMS microphones. Therefore, the product designer must consider several factors while selecting MEMS microphones for electronic circuit design.

Some of the essential characteristics and factors are as follows:

Configuration – top versus bottom port

MEMS microphone packages require a hole so the sound waves can reach the diaphragm. This hole can either be placed on the package lid (top port) or at the bottom near the solder pads (bottom port). The selection of top or bottom port microphones depends on many factors, such as space constraints, microphone location, and circuit board design. Usually, bottom port microphones deliver better performance than their top port counterparts.

Signal-to-noise ratio

The signal-to-noise ratio (SNR) is the ratio between the microphone’s sensitivity and its noise floor and is among the most critical considerations for microphone selection. SNR range for typical MEMS microphones lies between 55dB and 66dB.

Sensitivity

Sensitivity, defined as the ratio of analogue output voltage or digital output value to input pressure, is an essential feature of any microphone.

The lowest sound pressure level that a MEMS microphone can detect is its sensitivity. The sensitivity of MEMS microphones is tested at 1kHz frequency and 1Pa sound pressure. The sensitivity of analogue MEMS microphones is expressed in mVRMS/Pa or dBV/Pa, whereas the sensitivity of digital MEMS microphones is in dBFS (relative to full-scale output).

High-sensitivity microphones are not always superior to low-sensitivity microphones. The sensitivity indicates the microphone’s characteristics but not necessarily its quality.

This article explains that Understanding Microphone Sensitivity is crucial for any engineering during the microphone selection.

Power consumption

Power consumption is one of the most critical design considerations, especially for portable and handheld electronic devices. Therefore, the selection of power-efficient MEMS microphones is crucial. Compared to conventional microphones, MEMS microphones consume less power because all the circuitry is housed in a single IC package. Moreover, analogue MEMS sensors consume less energy than digital ones because of fewer stages.

Dimensions

The microphone size is another important consideration in the design of modern portable electronic devices. Electronic gadgets are shrinking daily, and available space is quite limited. MEMS microphones are excellent in this regard because of their small form factor. Due to this reason, manufacturers use these microphones in tablets, mobile phones, smartwatches, and other portable devices.

Noise floor

Noise, EMI, and buzzing are the biggest challenges in high-frequency electronic circuits. Distortion in output signal can lead to erroneous results and poor quality. The amount of noise in the output signal in a quiet environment is known as the microphone’s noise floor. Noise levels directly impact the SNR of the microphone. Analogue microphones are more susceptible to noise than digital microphones. MEMS microphones feature on-chip signal conditioning circuitry to minimize noise and interference.

Distortion

Total Harmonic Distortion (THD) is the deviation of a signal from its actual waveform. Signal distortion in an audio system can cause poor sound quality and user experience. The most common cause of signal distortion is various types of noise and interference.

Frequency response

Frequency response is the variation in microphone sensitivity at different frequencies. The typical frequency range within which MEMS sensors operate satisfactorily lies between 100Hz and 10 kHz. As a result, high-performance MEMS microphones provide a flat frequency response over the entire audible range, i.e. 20 Hz to 20 kHz.

These ranges are key in products like earbuds & Headphones

Power supply rejection

PSR is another critical factor in the selection of MEMS microphones. The ability of the microphone to reject the power supply noise is known as PSR. In poor-quality microphones, the power supply noise often appears at the output signal, which causes distortion and sound quality issues.

Directionality

Board-level microphones can either be omni or uni-directional. Uni-directional microphones can only gather sound from a particular direction, while omnidirectional microphones can receive sound from any direction. Therefore, the directionality of a microphone is a crucial factor in its selection for a specific application.