Mechanical and physical properties, classes and fastener grades of carbon steel and alloy steel, which depend on their load strength.

In product design and manufacturing, the selection of fasteners is pivotal in ensuring assembled components’ structural integrity, reliability, and overall performance. Fasteners, such as bolts, screws, nuts, and rivets, act as the linchpin that holds together various parts, contributing to the durability and safety of the final product. Among the myriad factors influencing the choice of fasteners, understanding their mechanical properties, primarily in the context of carbon steel and alloy steel, is paramount.

Designation system for property classes

Bolt, screw, and stud property classes are represented by two numbers separated by a dot, as shown by the image below and typically referred to as “Fastener grades”.

- The number to the left of the dot is one or two digits long and represents one-hundredth of the nominal tensile strength in megapascals.

- The number to the right of the dot represents ten times the ratio of nominal yield strength to nominal tensile strength.

- Zero to the left of the property class designation indicates that fasteners have a lower Loadability.

A fastener with the property class designation 8.8 has a nominal tensile strength Rm, nom = 800 MPa and a yield strength ratio of 0.8.

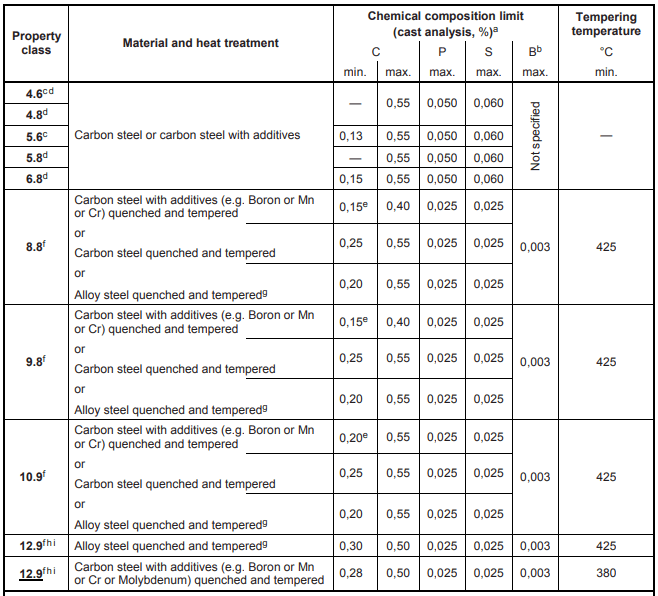

The table below specifies the chemical composition of steels as well as the minimum tempering temperatures for the various property classes of bolts, screws, and studs.

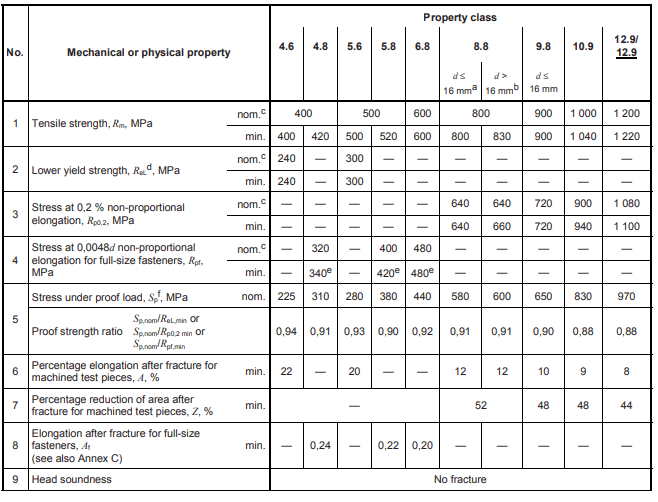

Mechanical and physical properties classes and grades

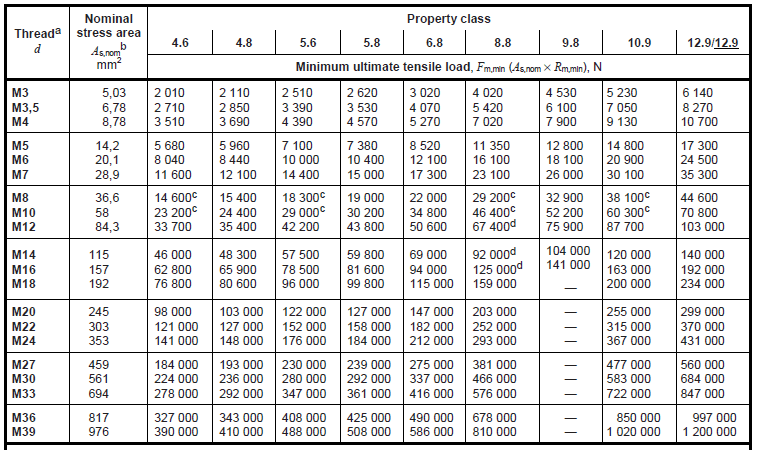

Minimum ultimate tensile loads

Minimum ultimate tensile loads — ISO metric coarse pitch thread

These are from standard BS EN ISO 898-1:2013 and can be purchased from here.

ISO 898 is a global standard that specifies metric fasteners’ mechanical and physical properties. This standard is based on other standards that define properties for similar metric fasteners, such as SAE J1199 and ASTM F568M. It is divided into five (non-contiguous) sections:

- Bolts, screws, and studs with specific property classes – coarse and fine-pitch thread

- Coarse thread nuts with specified proof load values

- Set screws and similar threaded fasteners that are not subjected to tensile stresses

- Fine-pitch threaded nuts with specified proof load values

- Torsional test and minimum torques for bolts and screws with nominal diameters ranging from 1 mm to 10 mm