Metal Forging is a deformation process in which the metal billet is compressed between two dies to form a part.

Contents covered in this article

What is metal forging?

Metal forging is a group of forming processes in which a billet or a workpiece is deformed plastically between two dies or tooling by applying compression force. Although forging can be performed in all temperature ranges, such as hot, cold, warm, and isothermal, the most common forging type is done with a workpiece above its re-crystallization temperature. Forging is one of the most important metal-forming processes, especially in iron and steel manufacturing.

Forging, one of the oldest and most significant metallurgical procedures, was first used around 4000 B.C. to manufacture jewellery, coins, and numerous utensils by pounding metal with stone tools. Modern forging still follows the same concept as the local blacksmith, but high-powered hammers and mechanical presses have replaced the strong arm and the hammer, and tool steel dies have replaced the anvil.

Turbine rotors, gears, bolts and rivets, cutlery, hand tools, various structural components for machines, aviation, railways, and a range of other transportation equipment are now successfully forged.

Forging processes generate isolated components. Because the material’s metal flow and grain structure can be controlled, forged objects have exceptional strength and toughness. They are especially reliable for highly stressed and critical applications.

Characteristics of Metal Forging

- Forged parts have good strength and toughness and are used on critical parts because of their reliability for highly stressed and critical applications.

- Forging usually produces little or no scrap hence comparatively cheaper for medium to large production batches.

- The forging process can quickly generate the final part geometry, usually in one or a few hammer strokes.

Metal forging advantages and disadvantages

Metal forging advantages

- When compared to casting, forging produces a more durable product.

- Forge products have greater fatigue strength and creep resistance.

- The mechanical qualities of forged products are superior.

- The operation is low-cost.

- This procedure does not necessitate the use of a skilled operator.

- This method may produce a wide range of forms.

Metal forging disadvantages

- Higher equipment costs for large forging presses are costly compared to other manufacturing processes.

- A secondary finishing procedure might be necessary.

- It is incapable of producing complicated forms.

- The forging part size is limited due to the press size.

- Brittle metal is incapable of being forged.

Hot forging and cold forging

Cold forging compresses metal at ambient temperature, whereas hot forging necessitates a high heat level. Cold and hot forgings are distinguished by the intense hot forging heat, which permits the metal to take on more sophisticated and complicated shapes than cold forging.

Hot Forging

The temperature of hot forging varies based on the type of metal. The hot forging process begins with the dies being heated to avoid any temperature loss throughout the operation and to guarantee that crystallization does not occur until the forming is complete. The metal becomes more ductile when it is heated. When the hot metal is squeezed by the dies, the structure changes into a more refined grain, which increases yield strength and ductility.

Cold Forging

The material is shaped into the required shape via a displacement technique in cold forging. A compressive force squeezes the metal between a punch and a die at normal temperature until it conforms to the die’s outlines. Rolling, pressing, drawing, spinning, heading, and extruding are all examples of cold forging methods.

Metal forging types

- Open-die forging

- Closed die-forging or Impression forging

- Flashless forging

Open die forging

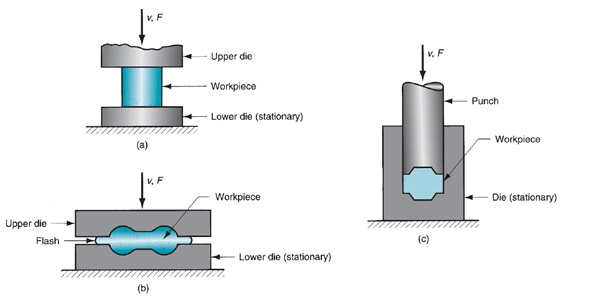

In the most basic open-die forging, two flat dies compress a cylindrical cross-sectioned workpiece, similar to a compression test. Open die forging, also known as upset forging or upsetting, allows the metal to flow around and increase in diameter without constraint while the workpiece reduces in height.

An essential industrial technique is open-die hot forging. Shafts, discs, and rings are examples of basic shapes produced by open-die processes. Dies with slightly curved surfaces assist in shaping the work in various applications. Furthermore, the work must frequently be adjusted (e.g., rotated in stages) to achieve the appropriate form change. The human operator’s skill is an important aspect of the success of these procedures. The shaping of a huge square cast ingot into a circular cross-section is an example of open die forging in the steel industry. Open die forging produces crude shapes, which must be refined with successive processes to get the final geometry and dimensions. The ability of open-die hot-forging to establish a favourable grain flow and metallurgical structure in the metal is a significant benefit.

As shown in the diagram above, fullering, edging, and cogging are examples of open-die forging or similar operations. Fullering is a forging procedure that reduces the cross-section of a workpiece and redistributes the metal in preparation for shape forging. Dies with convex surfaces are used to achieve this. Multi-cavity impression dies commonly have fullering die cavities, so the beginning bar may be roughly formed before the final shape. Edging is identical to fullering, except that the dies are concave. Cogging is a method of lowering the cross-section and lengthening a workpiece by applying a sequence of forging compressions down its length. It’s used to make blooms and slabs from cast ingots in the steel industry. It’s done with open dies that have flat or slightly curved surfaces. This procedure is frequently referred to as incremental forging.

Open die forging advantages

- Tooling costs are minimal or non-existent.

- Reduced time to market

- Several sizes range from a few millimetres to approximately 100 feet.

Open die forging disadvantages

- Not ideal for producing complicated, precise pieces or other applications requiring close tolerance.

- To finish open-die forgings, machining is frequently necessary.

- The process does not always yield consistent outputs or desirable characteristics.

Impression forging

Closed die forging pushes the dies towards each other, completely or partially enveloping the workpiece. The bottom die holds heated raw material that is close to the shape and size of the final forged object.

The form of the forging is included as a negative image into the top or bottom die in this procedure. When the process begins, the top die strikes the metal substance, forming it into the desired forged shape.

This method may make pieces weighing anywhere from a few ounces to 60,000 pounds.

Impression forging advantages

- Superior mechanical qualities and a better surface finish

- Machining is minimized or not done at all.

- For big manufacturing runs, it’s cost-effective.

- It is possible to attain dimensions with tighter tolerances and various forms.

- Impressions that are more exact and constant

- The ability to replicate almost any shape and size

Impression forging disadvantages

- Due to the high cost of die manufacture, it is not usually cost-effective for short or small production runs.

- Due to the high cost of machinery and furnaces, the setup cost is higher.

Flashless forging

In certain cases, impression dies forging is done in completely enclosed imprints. A near-net or net-form forging is created using this method. Because the method does not rely on the creation of a flash to achieve complete filling, the dies make no provision for it. A thin fin or ring of flash may form in the clearance between the top punch and die, but this may be readily eliminated with blasting or tumbling operations and does not need a trim die. As a result, the method is known as “flashless forging,” and it is also known as “enclosed die forging.”

Flashless forging advantages

- Waste of material is avoided, and energy is conserved.

- a high pace of manufacturing and a high level of dimension accuracy

- The final product has a distinct form.

- The completed portion has high strength.

- The final product has a higher ductility.

Flashless forging disadvantages

- Because of the complicated die form, tooling costs are higher.

- Doesn’t allow for the gradual growth of difficult-to-forge features across several stages of metal flow.

- To complete the cavity’s filling without creating excessive pressures, the metal volume in the workpiece must be regulated within extremely narrow limitations.

- Certain highly well-controlled performing stages are required to achieve this perfect weight control in the final die.

Recommended reading

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth edition ed.). London: Pearson.