During metal forming, the metal is plastically deformed by a force exceeding the material yield strength, where strain hardening occurs.

Contents covered in this article

What is metal forming?

Metal forming is one of the world’s most widely used manufacturing processes. During the forming process, the metal is plastically deformed by a force that exceeds the material yield strength, which is where strain hardening occurs.

The material should have a low yield strength and high ductility to form, while strain rate and lubrication also affect the performance successfully. Increasing the temperature reduces yield strength and increases ductility to make it easier to deform; hence, some types of forming are performed hot.

Types of Metal Forming

Forming processes tend to be categorised by different types of force and can be grouped into the following categories;

- Compressive stress forming

- Tensile stress forming

- Combine stress

- Bending

- Shearing

Further, these can be subdivided into various forms depending on how the force is applied.

Metal forming processes are classified based on the type of force applied during the deformation. Here are the main categories:

Compressive Stress Forming

In compress stress forming process the metal is compressed to change shape typically involve reduced thickness or increased density.

| Process | Material Options | Applications | Example Product Components |

| Forging | Steel, Aluminium, Titanium | Automotive, aerospace, industrial machinery | Crankshafts, gears, connecting rods |

| Rolling | Steel, Aluminium, Copper | Construction, automotive, shipbuilding | I-beams, sheet metal, steel plates |

Tensile Stress Forming

Processes where metal is stretched or drawn to reduce its cross-section and increase its length.

| Process | Material Options | Applications | Example Product Components |

| Drawing | Steel, Aluminium, Copper | Construction, electrical, automotive | Wire, rods, tubing |

| Deep Drawing | Steel, Aluminium, Copper | Automotive, packaging, consumer goods | Car body panels, beverage cans, plumbing fixtures |

Combined Stress Forming

Processes involving both compressive and tensile stresses to shape the metal is called Combined Stress Forming.

| Process | Material Options | Applications | Example Product Components |

| Extrusion | Aluminium, Copper, Steel | Construction, automotive, electronics | Window frames, heat sinks, structural sections |

| Hydroforming | Aluminium, Steel | Automotive, aerospace | Complex hollow components like exhaust manifolds, structural parts |

These processes are essential for shaping metal into various components used in numerous industries, ensuring that the final products meet specific design and performance criteria.

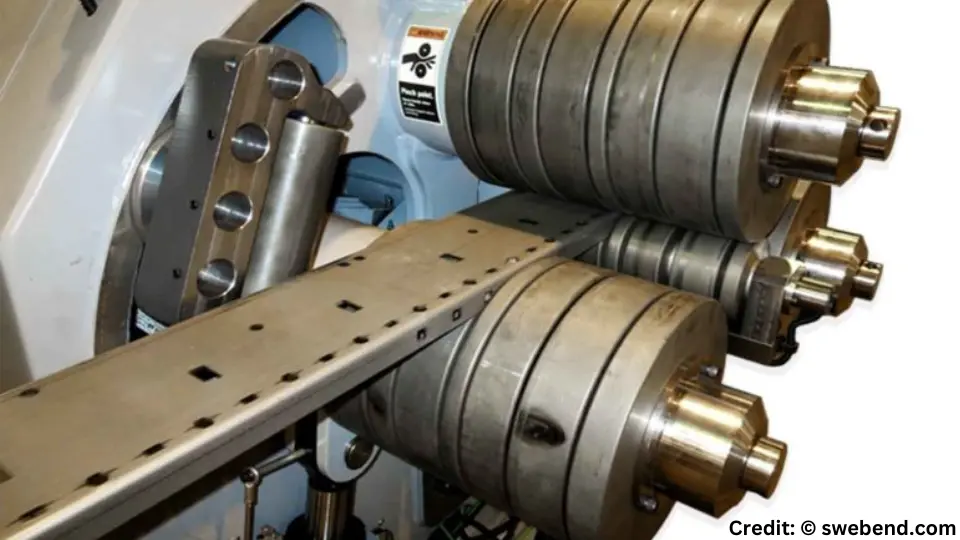

Rolling

Metal rolling is a manufacturing process where metal stock is passed through one or more pairs of rolls to reduce thickness, improve uniformity, or achieve a desired cross-sectional profile. This process can occur at various temperatures, resulting in hot rolling (high temperatures) or cold rolling (room temperature). Rolling is essential for producing sheet metal, structural components, and other products with consistent thickness and properties.

Material Options and Applications

| Material | Applications | Example Product Components |

| Steel | Construction, automotive, shipbuilding | I-beams, sheet metal, steel plates |

| Aluminium | Aerospace, packaging, automotive | Foil, beverage cans, automotive body panels |

| Copper | Electrical, construction, electronics | Wiring, roofing, printed circuit boards |

| Brass | Decorative items, musical instruments, plumbing | Instrument parts, fittings, decorative panels |

| Stainless Steel | Food processing, medical, construction | Kitchen equipment, surgical instruments, building facades |

Example Product Components

- I-Beams (Steel): Structural elements used in construction for support and load-bearing applications.

- Foil (Aluminium): Thin sheets used in packaging, insulation, and cooking.

- Wiring (Copper): Conductive material used extensively in electrical systems and electronics.

- Fittings (Brass): Durable and corrosion-resistant components used in plumbing and fluid handling systems.

- Surgical Instruments (Stainless Steel): High-strength, corrosion-resistant tools used in medical procedures.

Forging

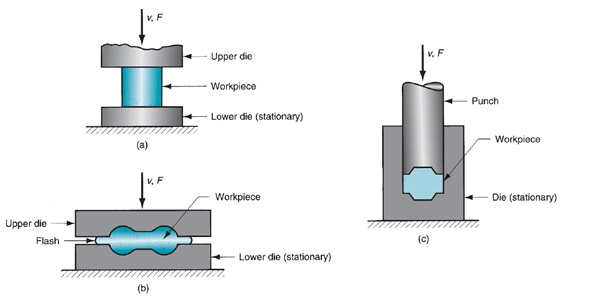

Forging deforms the metal between two dies, where the die shapes are imparted onto the raw metal piece. This can be either a hot or cold working process.

Metal forging is a manufacturing process in which metal is shaped by compressive forces applied through various tools, such as hammers or presses. This process can be performed at different temperatures, resulting in either hot forging, warm forging, or cold forging. Forging improves the mechanical properties of metals, such as strength and durability, making them suitable for critical components in various industries.

Material Options and Applications

| Material | Applications | Example Product Components |

| Steel | Automotive, aerospace, industrial machinery | Crankshafts, gears, connecting rods |

| Aluminium | Aerospace, automotive, consumer goods | Aircraft components, automotive suspension parts, bicycle frames |

| Titanium | Aerospace, medical, chemical processing | Jet engine components, orthopaedic implants, heat exchangers |

| Copper | Electrical, plumbing, industrial machinery | Electrical connectors, plumbing fittings, heat sinks |

| Brass | Plumbing, electrical, and decorative items | Valves, gears, musical instruments |

Example Product Components

- Crankshafts (Steel): Used in internal combustion engines to convert linear piston motion into rotational motion.

- Aircraft Components (Aluminium): Lightweight parts for aircraft structures, improving fuel efficiency and performance.

- Jet Engine Components (Titanium): High-strength and lightweight parts that can withstand extreme temperatures and stresses.

- Electrical Connectors (Copper): High-conductivity components essential for electrical power transmission.

- Valves (Brass): Durable and corrosion-resistant components used in plumbing and fluid control systems.

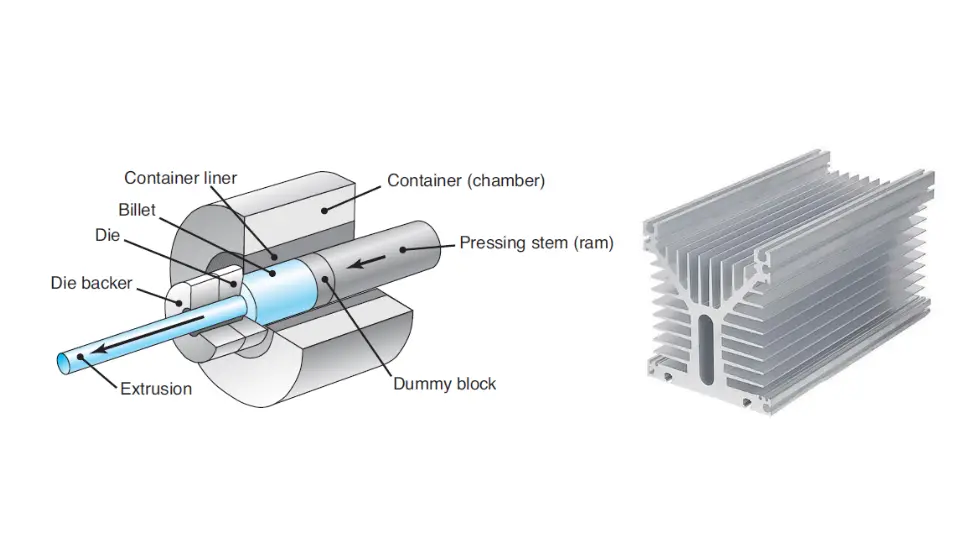

Extrusion

Metal extrusion is a manufacturing process that forces metal through a die to create objects with a fixed cross-sectional profile. This process can produce complex shapes and is often used for materials that are difficult to form by other methods. Extrusion can be performed hot or cold, depending on the material and desired properties of the final product.

Material Options and Applications

| Material | Applications | Example Product Components |

| Aluminium | Construction, automotive, electronics | Window frames, heat sinks, automotive parts |

| Copper | Electrical, plumbing, industrial machinery | Busbars, plumbing pipes, refrigeration tubing |

| Steel | Construction, machinery, automotive | Structural sections, rails, exhaust pipes |

| Magnesium | Aerospace, automotive, electronics | Aircraft components, automotive parts, electronic casings |

| Titanium | Aerospace, medical, chemical processing | Aircraft parts, medical implants, chemical processing equipment |

Example Product Components

- Window Frames (Aluminium): Lightweight, corrosion-resistant frames used in building construction.

- Heat Sinks (Aluminium): Components dissipate heat in electronic devices.

- Busbars (Copper): Conductive bars used in electrical power distribution.

- Structural Sections (Steel): Various profiles (e.g., channels, angles) used in construction and machinery.

- Aircraft Parts (Magnesium): Lightweight and strong components used to reduce overall aircraft weight and improve fuel efficiency.

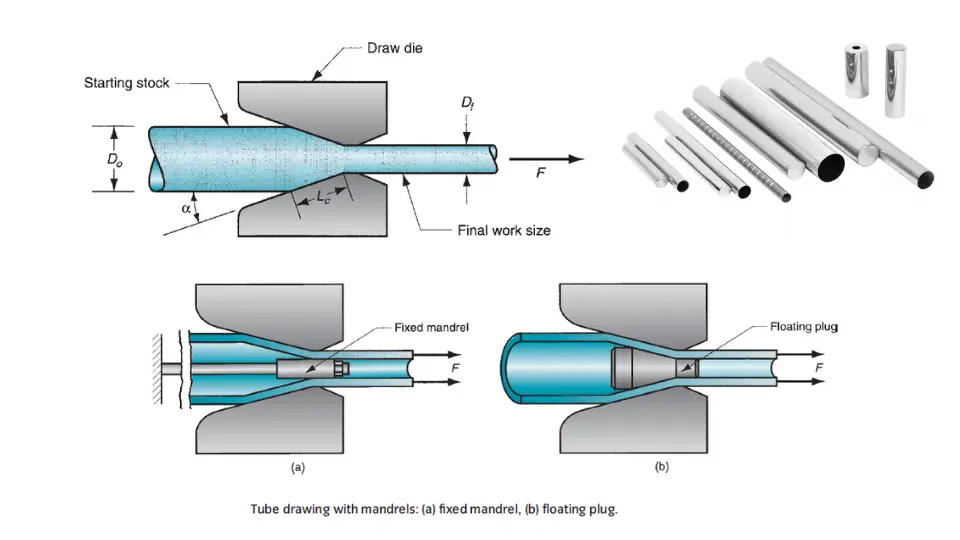

Drawing

Metal drawing is a manufacturing process in which metal is pulled through a die to reduce its cross-sectional area, increase its length, and improve its mechanical properties. This process is commonly used to produce wires, rods, and tubes. Depending on the material and desired properties, it can be performed at room temperature (cold drawing) or elevated temperatures (hot drawing).

Material Options and Applications

| Material | Applications | Example Product Components |

| Steel | Construction, automotive, industrial machinery | Wire, nails, rods |

| Aluminium | Electrical, construction, aerospace | Electrical wires, tubing, rivets |

| Copper | Electrical, plumbing, electronics | Electrical wires, plumbing pipes, connectors |

| Brass | Musical instruments, plumbing, electrical components | Instrument strings, fittings, connectors |

| Titanium | Aerospace, medical, industrial machinery | Medical wires, aerospace fasteners, springs |

Example Product Components

- Wire (Steel): Used in construction (rebar ties), automotive (control cables), and industrial applications.

- Electrical Wires (Aluminium): Conductive wires used in power transmission and distribution.

- Plumbing Pipes (Copper): Durable and corrosion-resistant pipes used in residential and commercial plumbing systems.

- Instrument Strings (Brass): Strings for guitars and pianos.

- Medical Wires (Titanium): Biocompatible wires used in medical implants and surgical instruments.

Metal Deep Drawing

Metal deep drawing is a manufacturing process in which a metal sheet is radially drawn into a forming die by the mechanical action of a punch. It is used to produce hollow-shaped parts with significant depth compared to their diameter. This process can create complex, high-strength components and is typically performed at room temperature, although it can sometimes be done at elevated temperatures.

Material options and Applications

| Material | Applications | Example Product Components |

| Steel | Automotive, appliance, construction | Car body panels, fuel tanks, kitchen sinks |

| Aluminum | Aerospace, packaging, automotive | Beverage cans, aircraft panels, battery casings |

| Copper | Electrical, industrial machinery, consumer goods | Electrical connectors, plumbing fixtures, decorative items |

| Brass | Plumbing, electrical, decorative items | Valve bodies, electrical connectors, ornamental hardware |

| Stainless Steel | Food processing, medical, automotive | Cookware, surgical instruments, exhaust components |

Example Product Components

- Car Body Panels (Steel): High-strength and durable panels used in the construction of vehicle bodies.

- Beverage Cans (Aluminum): Lightweight and corrosion-resistant cans used for packaging drinks.

- Electrical Connectors (Copper): Conductive and formable components used in electrical systems.

- Valve Bodies (Brass): Durable and corrosion-resistant parts used in plumbing systems.

Cookware (Stainless Steel): High-strength, heat-resistant, hygienic pots and pans used in kitchens.

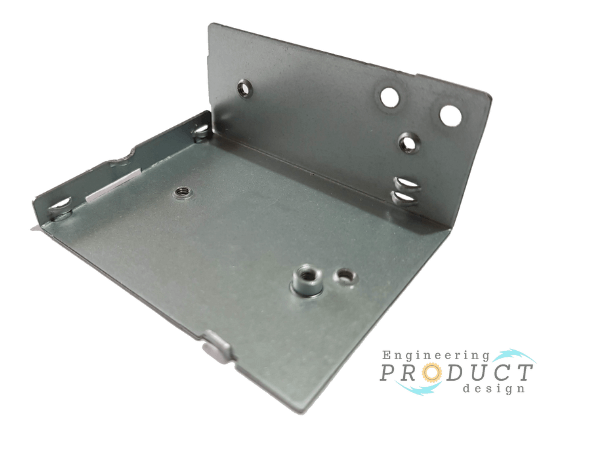

Sheet metal forming

What is Sheet metal forming?

Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet metal parts. Because manufacturers typically perform these operations on presses with a set of dies, the terms pressworking or press forming are also commonly used in industry to describe them.

Typical metal sheets measure between 0.4 (1/64”) mm and 6 mm (1/4) and are widely used across consumer and industrial applications such as beverage cans, automobile bodies, aircraft fuselages, appliances, metal furniture and filing cabinets. Sheet metal forming processes are typically performed at room temperature on machined tools called Presses using Dies. The parts are referred to as “Stampings”.

Sheet metalworking processes

Sheet metalworking processes are classified into three categories: bending, sheet metal drawing, and shearing.

- Shearing – Cutting

- Shearing

- Blanking

- Punching

- Bending

- Drawing

Shearing

Shearing, as the name suggests, cuts the sheet metal using a punch and a die by applying shear stress. Shearing is a metal cutting process where a workpiece is cut or separated into two or more pieces along a straight line using a shear blade or a punch and die setup. This process is commonly used to cut sheet metal or plates to size or trim edges.

| Process | Material Options | Applications | Example Product Components |

| Shearing | Steel, Aluminium, Copper | Sheet metal fabrication, automotive, construction | Sheet metal blanks, plates, strips |

| Blanking | Steel, Aluminium | Automotive, electronics | Disks, washers, electronic enclosures |

Material Options and Applications

| Material | Applications | Example Product Components |

| Steel | Automotive, construction, manufacturing | Sheet metal blanks, panels, brackets |

| Aluminium | Aerospace, automotive, packaging | Enclosures, covers, brackets |

| Copper | Electrical, plumbing, electronics | Busbars, connectors, heat sinks |

| Brass | Hardware, decorative items, musical instruments | Fasteners, fittings, instrument parts |

| Stainless Steel | Food processing, medical, marine | Kitchen equipment, medical instruments, boat fittings |

Example Product Components

- Sheet Metal Blanks (Steel): Shearing cuts sheet metal into blanks for further processing, such as stamping or forming, to create components for automotive, construction, or manufacturing industries.

- Enclosures (Aluminium): Aluminium sheet metal is sheared and formed into enclosures for electronic devices, control panels, or lighting fixtures.

- Busbars (Copper): Copper sheet metal is sheared to size and shape to create busbars used in electrical power distribution systems.

- Fasteners (Brass): Brass sheet metal is sheared and machined to produce fasteners like screws, nuts, and bolts for various applications.

- Kitchen Equipment (Stainless Steel): Stainless steel sheet metal is sheared and formed into components for kitchen equipment such as sinks, countertops, and cabinets.

Bending

Bending is a metal forming process where a workpiece is deformed along a straight axis, resulting in a change in its shape, typically to create curves or angles. This process commonly uses press brakes, roll benders, or tube benders.

| Process | Material Options | Applications | Example Product Components |

| Bending | Steel, Aluminum, Copper | Construction, automotive, consumer goods | Pipes, brackets, frames |

| Roll Bending | Steel, Aluminum | Construction, shipbuilding | Large curved beams, hull sections |

Material Options and Applications

| Material | Applications | Example Product Components |

| Steel | Construction, automotive, machinery | Pipes, beams, brackets |

| Aluminium | Aerospace, automotive, consumer goods | Extruded profiles, tubing, frames |

| Copper | Electrical, plumbing, HVAC systems | Piping, tubing, connectors |

| Brass | Musical instruments, hardware, decorative items | Instrument parts, fittings, architectural accents |

| Stainless Steel | Food processing, medical, marine | Kitchen equipment, railing systems, boat fittings |

Example Product Components

- Pipes (Steel): Bent pipes are used extensively in plumbing, HVAC systems, and structural applications for fluid transport and structural support.

- Extruded Profiles (Aluminium): Aluminium profiles are bent to create frames for windows, doors, and curtain walls in construction and architectural applications.

- Electrical Conduit (Copper): Copper tubing is bent to form electrical conduits used for housing and protecting electrical wiring.

- Instrument Parts (Brass): Brass is commonly bent to create various components for musical instruments, such as trumpet bells or saxophone bodies.

- Kitchen Equipment (Stainless Steel): Stainless steel sheets are bent to form sinks, countertops, and shelves for kitchen and food service applications.

Sheet metal forming advantages and disadvantages

Advantages of sheet metalworking

- Sheet metal is strong and durable

- Due to its malleability it can be formed into various shapes while retaining its strength and structural integrity.

- Wide range of materials

- Low cost compared to processes such as forging, casting, and extrusion.

Disadvantages of sheet metalworking

- High tooling and equipment costs

- Cost for Complex Designs

- Slower Production Process

- Aesthetic Appearance

Sheet metal forming materials

Because of their low cost and generally good strength and formability, low-carbon steel sheets are the most common and widely used.

- Aluminium alloys

- Stainless steel

- Carbon steel

- Alloy steel

- Tool steel

- Galvanized steel

Temperature conditions of Metal forming

Cold Forming – It is performed at or near room temperature and offers advantages such as a better surface finish, increased strength through work hardening, and tighter tolerances.

Hot Forming – Performed at elevated temperatures, typically above the metal’s recrystallisation temperature. It allows for easier deformation and is used for larger or more complex shapes.

Warm Forming – Done at intermediate temperatures, balancing the benefits of both hot and cold forming.

Materials – Metal forming

Steel, aluminium, copper, brass, and titanium are commonly used metals. Each material behaves differently under deformation, influencing the choice of forming method and process parameters.

| Material | Common Products Examples |

| Steel | Automotive body panels, structural beams, gears, pipes |

| Aluminium | Aircraft components, beverage cans, window frames, heat sinks |

| Copper | Electrical wiring, plumbing pipes, connectors, heat exchangers |

| Brass | Plumbing fittings, musical instrument components, decorative items |

| Stainless Steel | Kitchen equipment, surgical instruments, architectural components |

Applications of Metal Forming

Metal forming processes find application across various industries due to their versatility in shaping metals into desired components. Here are some common applications with examples:

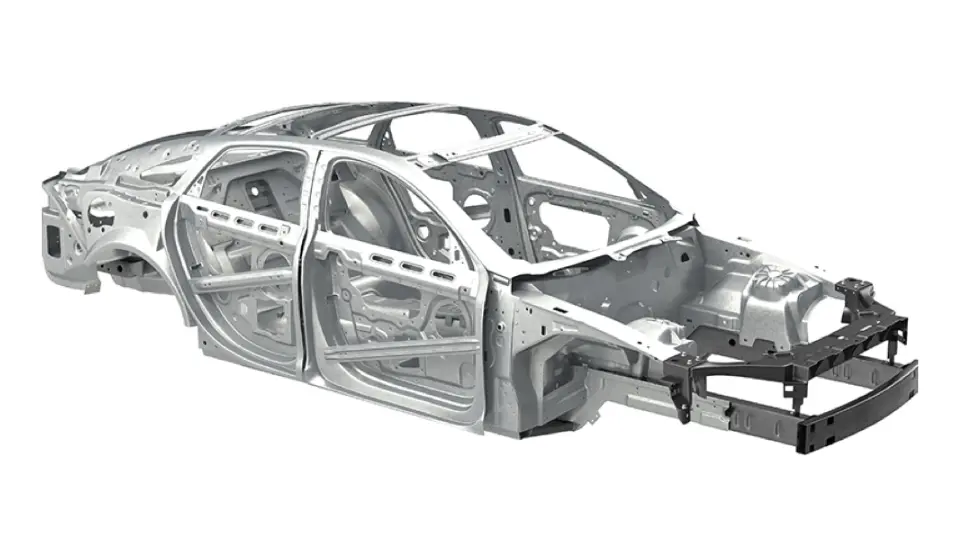

Automotive Industry

- Body Panels: Forming processes like stamping and deep drawing manufacture car body panels such as doors, hoods, and fenders.

- Engine Components: Forged components like crankshafts, connecting rods, and camshafts are critical for power transmission and control in automotive engines.

- Suspension Parts: Cold forming and extrusion produce control arms, sway bars, and suspension springs.

- Exhaust Systems: Tube bending and forming techniques fabricate exhaust pipes and mufflers with specific geometries.

- Structural Components: Roll forming and bending are utilised to produce structural components like chassis rails and reinforcements for vehicle frames.

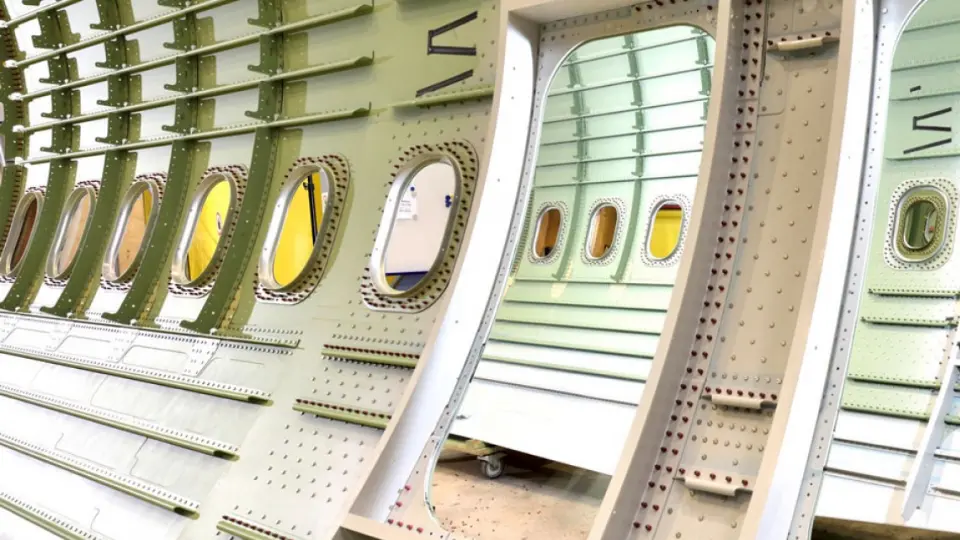

Aerospace Industry

- Aircraft Fuselage: Extrusion and stretch forming are employed to manufacture aircraft fuselage sections with complex shapes and precise dimensions.

- Wing Components: Forming processes such as roll forming and hydroforming fabricate wing ribs, spars, and skin panels.

- Engine Parts: Forging and hot forming produce engine components like turbine blades, compressor disks, and fan casings.

- Landing Gear: Cold forming and bending techniques fabricate landing gear components such as struts, braces, and axles.

- Interior Components: Deep drawing and stamping processes produce interior components like seat frames, panels, and brackets.

Construction Industry

- Structural Steel: Rolling processes produce structural steel beams, columns, and channels for building construction.

- Sheet Metal Roofing: Cold forming techniques, such as roll forming and bending, are employed to fabricate sheet metal roofing panels and flashings.

- Pipes and Tubes: Extrusion and drawing processes manufacture pipes and tubes for plumbing, HVAC systems, and structural applications.

- Decorative Components: Stamping and embossing processes produce decorative metal components such as ornaments, railings, and facades.

- Fasteners and Fittings: Cold heading and extrusion processes are used to produce fasteners (screws, bolts) and fittings (brackets, anchors) for construction applications.

Consumer Goods

- Kitchenware: Deep drawing and spinning processes manufacture stainless steel pots, pans, and utensils with smooth surfaces and precise shapes.

- Appliances: Stamping and forming processes fabricate components for appliances such as washing machine drums, refrigerator shelves, and oven panels.

- Electronics Enclosures: Sheet metal forming processes like bending and shearing produce enclosures for electronic devices, control panels, and cabinets.

- Furniture Components: Tube bending and forming processes are applied to manufacture metal furniture components like frames, legs, and brackets.

- Sporting Goods: Cold forging and extrusion processes produce components for sporting goods such as bicycle frames, golf club heads, and firearm parts.

Metal forming processes are crucial in manufacturing various components across various industries. They enable the production of complex shapes, precise dimensions, and high-strength materials essential for modern applications.

Advantages and disadvantages of Metal forming

Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing. However, they come with challenges, such as high initial costs, material limitations, and the need for precise process control. Balancing these advantages and disadvantages is crucial for selecting the appropriate application-forming process.

Advantages

- Improved Mechanical Properties – Metal forming processes can enhance metals’ strength, toughness, and ductility due to grain refinement and work hardening during deformation.

- Material Efficiency – These processes produce less waste than machining, as they shape the metal without removing material.

- High Production Rates – Metal forming processes, especially in high-volume production settings, can achieve high throughput and are often automated, leading to efficient manufacturing.

- Cost-Effective for Large Quantities – Although initial tooling and setup costs can be high, the per-unit cost decreases significantly with large production volumes.

- Versatility in Shapes and Sizes – Metal forming can produce various shapes and sizes, from simple to complex geometries, making it suitable for many applications.

- Surface Finish and Precision – Processes like cold forming can achieve good surface finishes and tight tolerances, reducing the need for additional machining or finishing.

Disadvantages

- High Initial Costs – The cost of dies, moulds, and specialised equipment can be substantial, making it less economical for low-volume production runs.

- Material Limitations – Not all metals are suitable for all types of forming processes. Brittle materials may crack under certain forming conditions.

- Tool Wear and Maintenance – The tools and dies used in metal forming processes are subject to wear and require regular maintenance or replacement, which increases operational costs.

- Energy Intensive – Some forming processes, particularly hot forming, require significant energy, contributing to higher operational costs and environmental impact.

- Complex Process Control – Achieving consistent quality in metal forming can be challenging and requires precise control of process parameters such as temperature, force, and speed.

- Residual Stresses – Forming processes can introduce residual stresses into the metal, which may affect its performance and require additional processes like stress relieving.

Reference and Recommended reading

- Beeley, P. (2001). Foundry Technology (Second ed.). Oxford: Butterworth Heinemann.

- Hosford, W. F., & Caddell, R. M. (2007). Metal Forming: Mechanics and Metallurgy. Cambridge University Press.

- Todd, J. A., & Boothroyd, G. (2010). Fundamentals of Metal Forming. ASM International.

- Boljanovic, V. (2010). Sheet Metal Forming Processes and Die Design. Industrial Press.

- Beddoes, J., & Bibby, M. (2000). Principles of Metal Manufacturing Processes. Butterworth-Heinemann.

- Kalpakjian, S., & Schmid, S. R. (2013). Manufacturing Engineering and Technology. Pearson.

- Schuler, A., Kögler, P., & Grünberg, K. (2012). Metal Forming Handbook. Springer.

- Schröder, K. H. (2006). Handbook of Metal Forming. John Wiley & Sons.