Sheet lamination forms 3D objects by stacking material such as paper, plastic or metal foil and laminating them using welding, adhesive, heat or pressure.

What is Sheet Lamination?

Sheet lamination is one of the 7 types of additive manufacturing processes defined by ISO/ASTM 52900-2015. It is the process of building a 3D object by stacking and laminating thin sheets of material. The lamination method can be bonding, ultrasonic welding or brazing, while the final shape is achieved by laser cutting or CNC machining.

Out of all the 7 types of AM technologies, sheet lamination produces parts with the least additive resolution. However, its low cost and faster manufacturing time allow product designers to make low-fidelity prototypes from standard, easily available low-cost material.

Types of Sheet Lamination

Sheet lamination can be subdivided into groups based on the build material used, such as paper, plastic, metal or woven fibre composites or forming methods employed, such as CNC milling, laser cutting or aqua blasting. They can also be categorised further based on the lamination technique used to bond the sheets together, such as adhesive bonding, thermal bonding and ultrasonic welding. There are also variations in when they are formed. In some cases, they are formed and then bonded like the Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM) process, or they are bonded and formed like Ultrasonic Additive Manufacturing (UAM) process.

- Form then Bond process – Sheet material is cut to shape first and then bonded to the base or previous layer to create a 3D geometry.

- Bond then Form Process – In this process, as the name suggests, sheet material layers are bonded together before cutting them into the desired shape.

Considering all the above variations, sheet lamination can be categorised into the following 7 types;

- Laminated Object Manufacturing (LOM)

- Selective Lamination Composite Object Manufacturing (SLCOM)

- Plastic Sheet Lamination (PSL)

- Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM)

- Selective Deposition Lamination (SDL)

- Composite Based Additive Manufacturing (CBAM)

- Ultrasonic Additive Manufacturing (UAM)

How Sheet Lamination works

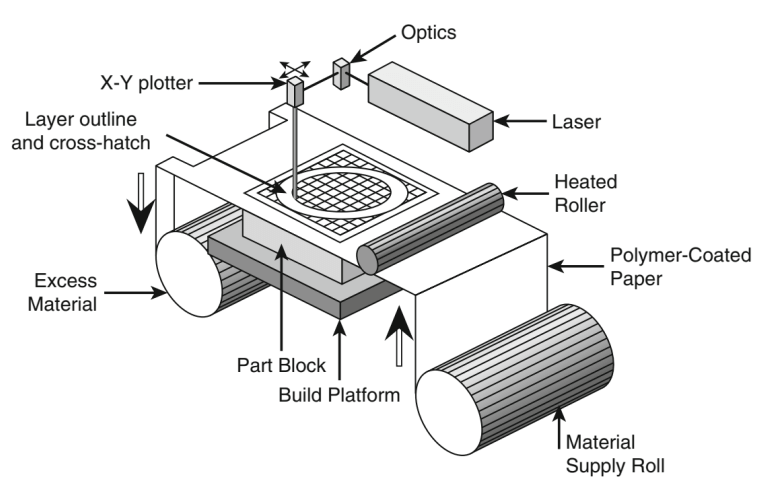

Every type of sheet lamination works marginally differently from the other, although the main principle is the same. A schematic overview is shown in below of the original laminated object manufacturing, which was the first commercialised additive manufacturing technique in 1991.

The initial part creation and setting up are the same for all 7 types of additive manufacturing technologies. It can be shown in 7 steps of how additive manufacturing works: 3D model creation, STL file creation, STL file transfer, Machine set up, Build, Part removal & post-processing.

First, a thin sheet of material is fed from the roller or placed onto the build platform. Depending on the type of sheet lamination, the next layer may or may not be bonded to the previous sheet. SDL and UAM bond the layers together and then cut the 3D shape at the end, while CAM-LEM cuts the layers into shape and then bonds the layers together. This process is continued until it completes all the layers to achieve the full height. Then the print block is removed, and all the unwanted outer edges are removed to reveal the printed 3D object.

In sheet lamination, the layer thickness is the same as the thickness of thin sheets of material and dictates the final quality. Layer thickness also depends on the machine and process used.

Material suitability

Although sheet lamination can use a wide variety of materials, such as paper, polymer, ceramic and metal, each material uses different binding methods. The most common sheet lamination material is paper with pre-applied adhesive, where heat and pressure activate the adhesive layer.

Polymers use heat and pressure without the adhesive as it relies on melting the sheets together. Metal sheets are bound using ultrasonic welding, while materials such as fibre-based material and ceramic use thermal energy in the form of oven baking to combine the layers.

| Process | Material options |

| LOM | Papers |

| PSL | Most polymers |

| SLCOM | Carbon Fibre, Fiberglass, Aramid Fibre (i.e. Kevlar), PBO (i.e. Zylon), along with metal fibres like steel, aluminium or titanium |

| CAM-LEM | Alumina Other ceramics available in our processes include zirconia, zirconia-toughened alumina (ZTA), silica, and a variety of oxide and non-oxide ceramics. |

| SDL | Standard paper |

| CBAM | Long-fibre fabrics bonded with thermoplastic matrix materials. Carbon fibre combined with either Nylon12, PEEK and glass fibre with Nylon 12 and PEEK |

| UAM | A wide range of material combinations can be printed as any material that can be welded in a single part opening the design space to enable property gradients and engineered material properties for increased performance. |

Typical application

Different types of sheet lamination techniques are used for different purposes and are directly tied to the individual process. Paper-based techniques such as LOM and SDL are used for full-colour prints, while metal-based sheet lamination is used in hybrid manufacturing.

SLCOM can make production-quality composite fibre parts, while the CAM-LEM process can be used to make ceramic parts.

Advantages and disadvantages of sheet lamination

Advantages of sheet lamination

- Faster print time, but post-processing will be required

- Ability to integrate hybrid manufacturing systems

- Ease of material handling

- Ceramic (CAM-LEM) and composite fibre (SLCOM) parts can be manufactured

- OEM components, such as sensors, wires, etc., can be embedded into the part during the layering stage. It highly depends on the sheet lamination technique and material used

- Relatively low cost as it uses standard material

- No support structures are necessary

- Larger working area than most of the current AM technology equipment

- Full-colour prints – LOM/SDL can print in the whole colour spectrum

- In some sheet lamination techniques, the material state does not change during or after the process

- Multi-material layers possible (UAM)

- In some cases, cut material can be easily recycled – This could also be a disadvantage if the part is smaller compared to the sheet or the bed size.

Disadvantages of sheet lamination

- Layer height cannot be changed without changing the sheet thickness hence part resolution is linked to sheet thickness along the vertical build axis.

- Finishes can vary depending on paper or plastic material but may require post-processing to achieve the desired effect.

- Limited material options available

- It can be time-consuming and difficult to remove the excess material after the laminating phase, and it generates a lot of waste compared to other AM methods.

- Hollow parts (internal voids and cavities) are difficult to produce in some sheet lamination processes, such as “bond then form.”

- Bonding strength will depend on the laminating technique used, and, in some cases, adhesive bonds are not good enough for long-term use of the product strength and integrity.

- Material waste can also be high if the part being made is smaller than the build area or the sheet size.