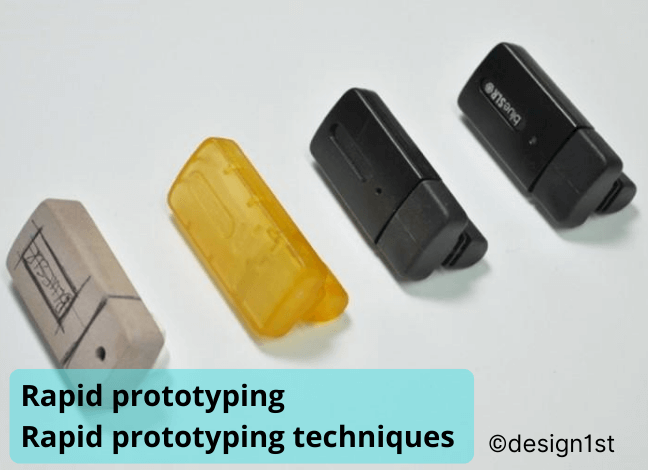

What is Additive manufacturing? | 7 Additive Manufacturing types

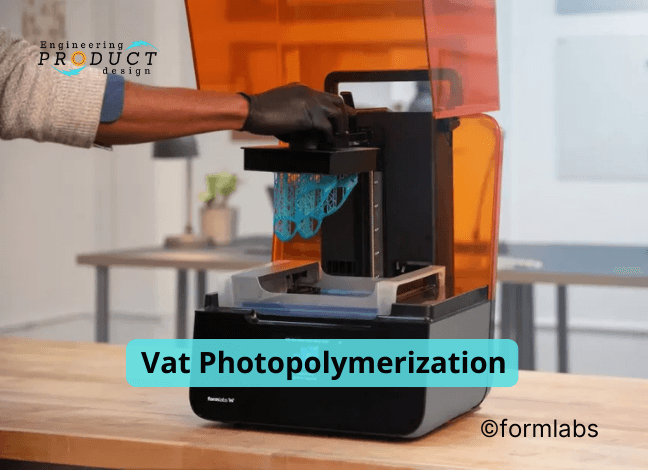

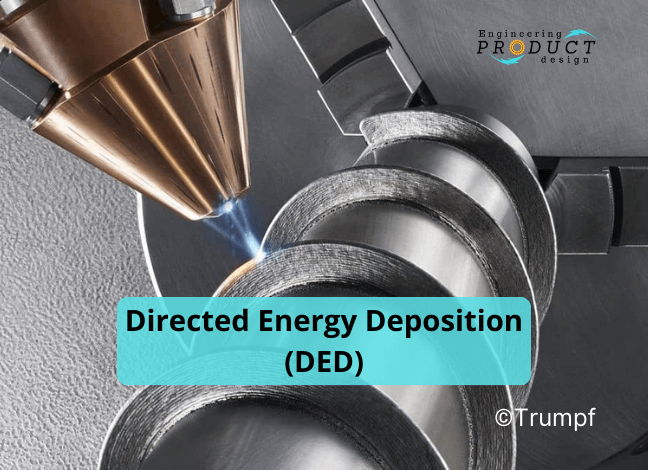

Additive manufacturing technology or 3D printing is type of technology that uses successive layers of material to create 3D objects

What is Additive manufacturing? | 7 Additive Manufacturing types Read More »