Centrifugal casting uses inertial forces induced by rotation to distribute molten metal into mould cavities to cast cylindrical

What is Centrifugal Casting?

Centrifugal casting refers to several casting techniques that use rotation’s centrifugal forces to distribute the molten metal to the outer regions of a circular mould cavity, where it solidifies to create a part.

This technology emerged in the early 1800s and can be a cost-effective method of creating complicated near-net shape parts compared to other manufacturing processes like forgings and fabrications.

Centrifugal casting types and their applications

True centrifugal casting, semi-centrifugal casting, and centrifuging are the three forms of centrifugal casting. The process is further divided into, Vertical and Horizontal, depending on their construction.

Centrifugal casting has a wide range of applications in the industry and is used to make parts such as bushings, engine cylinder liners, rings, brake drums, water supply lines, sewage pipes, street lamp posts and gas pipes.

They are used in high-reliability applications such as jet engine compressor cases, hydro wear rings, and numerous military items because they produce components with excellent material soundness due to very high centrifugal forces.

How does centrifugal casting work?

Like any other metal casting process, all three of the centrifugal casting processes follow the main casting steps of patternmaking, mould-making, melting, molten metal pouring and post-processing.

The centrifugal casting process marginally differs between the three types but can be generalised into the following steps.

- The mould wall is coated with a refractory ceramic coating. In the case of True centrifugal casting mould, it involves applying ceramic slurry while spinning, drying and then baking.

- Molten metal from an external source is directly poured into the mould without any gating system through a spout.

- The molten material for the casting can be poured into a rotating mould, or the mould can be rotated after it has been poured.

- The rotating mould’s centrifugal forces drive the molten material to the cavity’s outside wall once it’s inside.

- Once the desired amount of molten metal is poured, the mould continuously spins until the part is entirely hardened.

- The mould is removed and opened after the casting has solidified and the casting is removed.

True Centrifugal casting

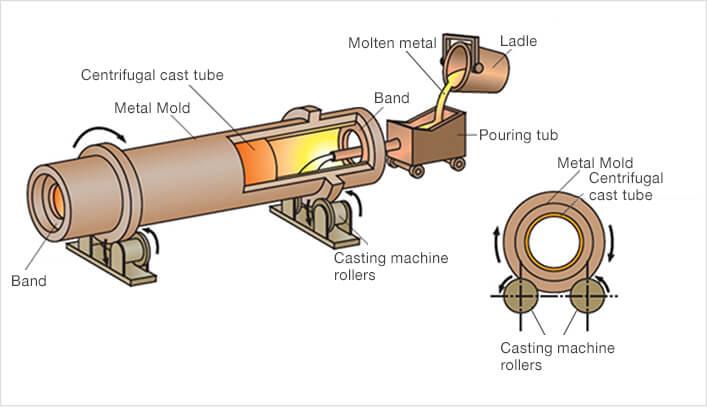

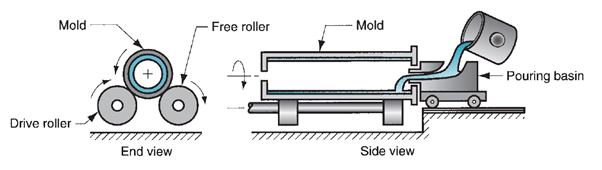

Molten metal is poured into a rotating horizontal mould to produce tubular parts such as pipes, tubes, rings, and bushes in this casting process. Mould rotation can occur on a horizontal or vertical axis, with the former being more common. The revolving speed of the horizontal true centrifugal casting is critical to the effectiveness of the casting process and part quality.

Moulds are made of steel, iron, or graphite and can be coated with a refractory lining to extend their life. The surfaces of the moulds are designed to allow for pipe casting with a range of outside styles. The inner surface of the casting remains cylindrical due to centrifugal forces that evenly distribute the molten metal.

Castings produced by true centrifugal casting have a high density, particularly in the outer portions of the component where centrifugal force is highest. Because centrifugal force constantly reallocates molten metal toward the mould wall during freezing, solidification shrinkage outside the cast tube is not an issue. Any imperfections in the casting tend to be on the inner wall and, if necessary, can be eliminated by machining.

How does True centrifugal casting work?

- Molten metal is poured straight into the mould without any gating mechanism.

- Once within the hollow, the centrifugal forces of the spinning mould propel the molten material to the cavity’s exterior wall.

- After the necessary amount of molten metal has been poured, the mould is rotated until the part is hardened.

- After the casting has been set, the mould is removed, opened, and the part removed for post-processing.

Advantages

- These castings have a high density, high mechanical strength, an excellent outer surface finish, and a fine-grained structure.

- Impurities and inclusions can be easily removed

- Gates are risers not required

- Hollow interiors without cores are formed.

- Can form very large parts with high accuracy

- Low equipment and labour cost

- Generates minimum scrap

Disadvantages

- The casting inner surface diameter will not be accurate.

- This method is not suitable for all alloys.

- The true centrifugal casting process is limited to cylindrical parts

- Secondary machining is often required for inner diameter

- Long lead time possible

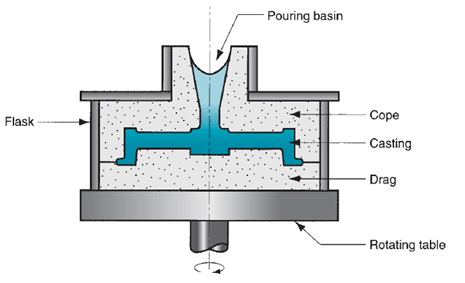

Semicentrifugal Casting

Semicentrifugal casting uses centrifugal force to produce solid casting rather than tubular casts. The image below shows an example of semi-centrifugal casting where the moulds have their riser at the axis of rotation to feed the molten metal. Expendable moulds are common and used to make parts such as spoked wheels, pulleys, gear blanks, brass bush and nozzles.

The exterior regions of items formed by semi-centrifugal casting have a higher density than the centre of the rotating axis. This casting procedure makes things like spoked wheels that have rotational symmetry and can remove the casting centre. Removing the centre section of the cast also removes the cast’s lowest-density component.

The quality of the final casting is affected by factors such as rotating speed, component diameter, pouring temperature, pouring speed, mould temperature, and cooling rate.

How does semi-centrifugal casting work?

- As shown above, the expendable mould is set up around the central sprue.

- Molten metal is then poured into the sprue slowly from an external source using a small spout.

- The molten material may be poured into a rotating mould, or the rotation of the mould may commence after the pouring has taken place.

- Pouring stops once the correct amount of molten metal for the casting, runner and sprue is poured.

- The spinning continues after the pouring and distribution and during the solidification process.

- The equipment will stop rotating after the castings have completely frozen, and the pieces may be removed.

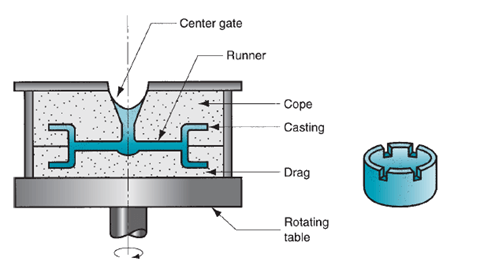

Centrifuging

Centrifuging, also known as centrifuge casting, involves the placement of mould cavities of any shape at a certain distance from the axis of spin. The molten metal is poured from the centre, and centrifugal forces push it into the mould cavity through the sprue and the runner. Like true centrifugal casting, the characteristics of the castings might change with distance from the spin axis. This method is used for small parts such as jewellery, small bushes and sleaves.

Centrifugal casting machines such as Neycraft, Tulsa, and Kerr, used to make jewellery and dental casting, are all based on the centrifugal casting technique.

How does Centrifuge casting work?

- As shown above, the mould is built to have cavities around the central sprue with runners connecting them.

- Molten metal is then poured into the sprue slowly from an external source using a small spout.

- The molten material may be poured into a rotating mould, or the rotation of the mould may commence after the pouring has taken place.

- The pouring stops once the correct amount of molten metal for the number of castings, runner and sprue is poured.

- The spinning continues after the pouring and distribution and during the solidification process.

- The mould will be stopped, and the components will be removed after the castings have been set.

Advantages

- Thin-walled and small parts are possible due to the centrifugal forces filling the cavity.

- Good surface finish due to the amount of forces imparted on the molten metal

- Since the cast parts are further away from the rotational axis, the part is denser

- Due to low density, impurities such as trapped gases and inclusions will be near the axis, away from the desired part

Disadvantages

- Not suitable for all the alloys

- Sprue and runner will have to be machined

Recommended reading

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth edition ed.). London: Pearson.