A product design process is the sequence of steps or activities a business employs to formulate, design, and manufacture a product. Typically, they are part of an overall New Product Development (NPD), where the companies create new products via efficient idea generation, concept development to manufacture and commercialisation.

Contents covered in this article

What is a Product Design Process?

A Product Design Process (PDP) is a set of planned activities that convert an idea into a product and make it commercially available to the end user.

In today’s world, modern technologies are a very complex social enterprise. Hence the product design process includes research and development, design, management, marketing, finance, manufacturing, production and maintenance.

Because of this complexity, an individual can’t manage this engineering product designs single-handedly. Due to this extent of multiple stakeholder involvement, it’s vital to have planned processes and effective communication across the stakeholders.

Hence, to increase the probability of a successful engineering product design, the planning and execution of a systematic design process are crucial.

Types of Product design processes

The design process may vary according to the products, such as whether they are tangible or intangible. For example, physical products such as smart watches, mobile phones and earphones are examples of tangible products where the product design process involves detailed design and manufacture. On the other hand, intangible products such as services, mobile phone applications, and computer software will have Implementation, testing, verification & Deployment instead of Detailed design and manufacture.

Product design processes also change depending on how the engineering product innovation is driven, whether Demand-pull innovation (Market-pull) or Invention-push (Technology-push) innovation. This article concentrates on the tangible engineering product design process.

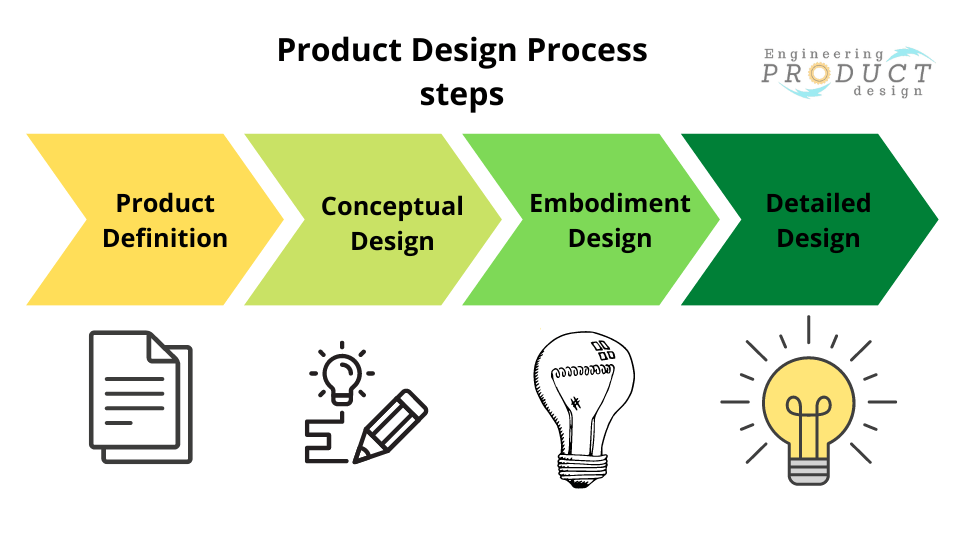

Product design process steps

Without a product design process plan, product designers would have an overwhelming number of options, given the process’s complexity and the numerous available methods. Designers must therefore become knowledgeable about the design process, various techniques, and the working and decision-making steps suggested in procedural plans.

In his book French. M.J. groups the product design process into the following four main phases: Problem analysis, Conceptual design, and embodiment of schemes and detailing. According to Koberg and Bagnell, the product design process typically involves Product analysis, Concept stage and Product Synthesis.

According to Pahl and Beitz, the design process needs to be broken down into phases and small steps, each with its procedures, to have a successful new product design. With this in mind, they split the process into four phases.

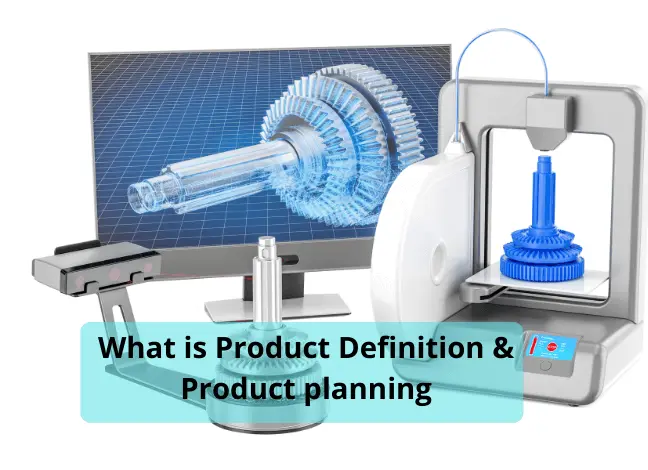

Product Definition – Product planning

Product definition is the most critical design step in a product design process, yet often overlooked by companies and product designers.

What is Product definition?

As the name implies, product definition defines the product in detail so the actual design can begin, and any subsequent steps rely on these requirement definitions. Depending on the nature of the product design, this is sometimes knowns as a “Problem definition” or “Product Planning” or “Task clarification“.

This step is distinct from the fuzzy front end, where product planning happens at the top level, such as marketing or the business.

Typically the product design and development task is given to the engineers and designers by either the marketing department or a client. Even if the requirement is captured in a document, the design team must clarify the requirement and start a Product Design Specification (PDS).

As a result of this activity, a comprehensive PDS in the form of a requirements list emphasising all technical, economic, and quality factors is produced.

Product Definition (PD) is, as the name implies, correctly identifying the requirement for the product. Therefore, product definition is the first step in Product Design Process (PDP), as shown in the image below, which starts the product design journey. This activity creates a thorough PDS in the form of a requirements list that emphasises all technical, economic, and quality factors. This PDS will be the input for the next conceptual design stage.

Depending on the business, product and NPD stage, it could also be called a “Needs analysis“, “Problem definition”, “Product planning”, and “Task clarification”.

- Product planning is generally done at the very early stage of the PDP or the new product development by product managers, marketing and management. Unfortunately for the product designers, some decisions about the PDP are made even before the engineering design process begins because of economic reasons.

- Task clarification is when the engineering takes over a client’s specification, which might be a partially fledge product specification.

- Understanding how customers perceive an organisation’s products, services, and brand involves conducting a customer needs analysis.

Why is Product Definition essential?

The product definition activity’s main objective is to understand the product requirement or problem thoroughly. No matter what type of product design the company is developing, the design team should first establish the technical requirement of the product by analysing the client’s requirement and creating a Product design specification (PDS).

The design and development team typically receives the product design request in one of the following ways.

- A written or verbal request from an external client or internal department with a problem statement

- A brief overview of core product requirements

- If it is a technology or innovation-driven requirement, then the design team has to come up with product ideas using the new technology.

Hence the product definition stage helps the design team to achieve the following;

- It ensures that the engineers and designers dissect and understand the requirement of the product.

- It produces a written official document, a PDS, against which the product can be verified and judged.

- It helps the client explain more in detail so the designers can understand the finer points.

How to define the product design

There are three key steps to defining a product requirement

- Identify requirements

- Gather information

- Create a Product Design Specification (PDS)

Conceptual design

Conceptual Design is an early phase of the design process, in which the broad outlines of the function and form of something are articulated.

What is Conceptual design?

Conceptual Design is an early phase of the design process, in which the broad outlines of the function and form of something are articulated. It includes the design of interactions, experiences, processes and strategies.

In an engineering product design environment, concept or conceptual design is an early stage of a product design process. Within the new product development cycle, it typically sits between the product definition and embodiment design.

The product requirement could be elaborate initially on demand-pull product developments, and the concept generation phase falls within the product design process.

But on technology-push new product development, the fuzzy front end is rather confusing as you have the technology (proven) at the start, but how that can be used to design products to sell is rather vague. Hence concept design falls at the start of with fuzzy end where you try out.

Within the fuzzy end of new product development, concept and technology development plays a crucial role in identifying the product’s range, design, etc. The concept or conceptual design stage concentrates on the chosen design within the product design phase.

Stages of Concept design

- Clarify the problem

- Search externally

- Search internally.

- Explore systematically

- Reflection and choosing the concept

Clarify the problem

- Understand the user and their needs

- Define the problem statement

- Identify the constraints

- Breakdown the problem into sub-problems

- Prioritise the sub-problems

Search externally

- Literature research

- Patent search

- Competitive analysis

- User interviews

- Expert consultations

- Industry events

Search Internally

- Talk to peers and collegues

- Review existing design and product documentation within your company

- Search company knowledgebase

- Organise and run brainstorming sessions using common brainstorming techniques

Explore systematically

- Identify the design variables

- Define the range of values for each design variable

- Generate all possible combinations of design variables

- Evaluate each combination of design variables

- Select the most promising combinations of design variables for further exploration

Reflection and choosing the concept

- Review your concepts

- Rank and prioritise concepts

- Evaluate your concepts against your criteria

- Get feedback from others

Benefits of Conceptual design stage

- The first advantage of conceptual design is that it clarifies what a product can do and its intended use. When developing a product, this is essential.

- Conceptual designs aid in producing a user interface that is simple to comprehend and use.

- To ensure that the project is better understood, it is beneficial to describe the roles of various users and their requirements thoroughly.

- The design will assist in carefully considering the user’s points of view, making achieving the desired results easier.

Concept design, also known as conceptual design, is an early stage of the design process in an engineering setting and results in the specification of a principle solution or so-called “Concept”.

There are several steps in the conceptual design phase, and if the most effective general solution is to be found, then the Designer should include all of them.

- Define the problem and refine the PDS

- Investigate the existing solutions

- Generate ideas and concepts

- Evaluate concepts

- Finalise concepts

Embodiment design

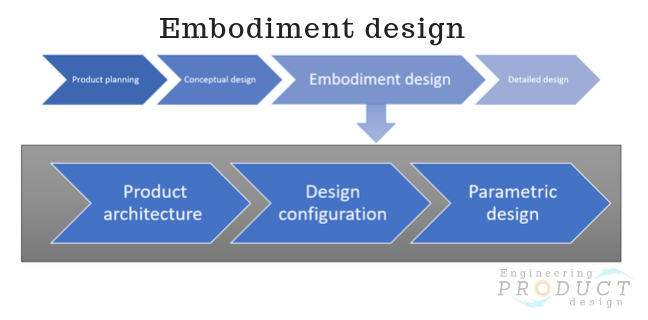

During the Embodiment design phase, the main concept is developed to a stage where detailed design can lead directly into production.

What is Embodiment design?

Embodiment design is one of the main stages of the product design process in which the main engineering product design concept is developed as per the product design specification (PDS) and economic criteria to a stage where subsequent detailed design can lead directly into production.

The embodiment product design phase of an engineering product design follows the concept design phase, where various concepts are generated and evaluated to produce a single final concept. (Figure 1)

In some literature sections, this phase is also referred to as preliminary or system-level design. Embodiment design was coined by Pahl and Beitz (2006) and adopted mostly by modern European engineering product design managers. Concept design followed by Embodiment design and detailed design is more suitable for an engineering product design hence this article uses these terms, although there are various product design process models.

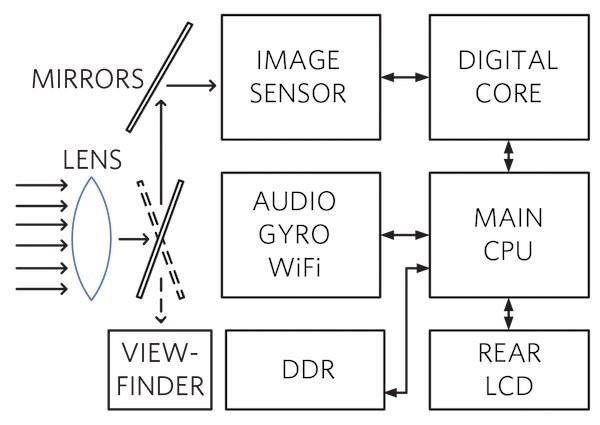

The output from the Concept design might vary from simple block diagrams (figure 2) to very early prototype concepts. It depends on what type of product development the company is pursuing.

Embodiment design phases

Embodiment design is a complex process as many design activities must be simultaneously performed, some of the design activities need to be repeated several times with changing data, and any changes in one section will influence another section of the design.

Every engineering product design is different and adds this to the above challenges, which is precisely why it’s very difficult to have strict set-out plans for the embodiment design phase.

So, at the embodiment stage of new product development, an abstract design concept will get moulded into a system or product that works and can be manufactured within the allocated unit cost.

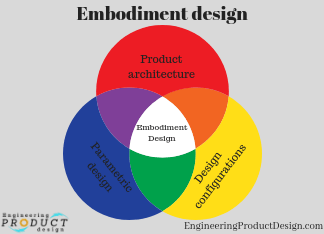

Embodiment design phase activities can be divided into three sections or phases (figure 3).

- Product architecture

- Design configuration

- Parametric design

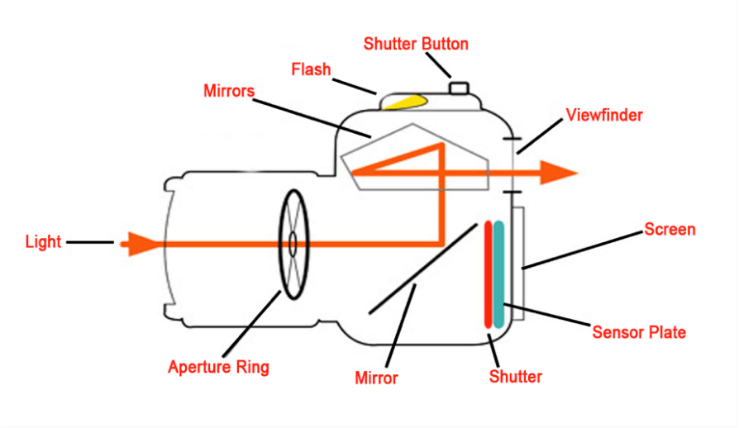

Product architecture

Product architecture, also referred to as System-level design, is, outlining and allocating physical components or entities to the function of a product. Physical elements are defined and arranged to satisfy the overall product requirement specification and are usually called modules.

Product architecture could start with very simple block diagrams, as shown in figure 4, or could be well thought out as an ongoing family of products.

System-level design is defined by how each subcomponent or modules interacts with each other at a product level and the function of each subcomponent. Product architecture is vital to any product development as it would impact the product evaluation and the cost of the product.

Product architecture can fall into two categories or styles. Modular and Integral.

Modular

In modular design, the overall product purpose or system-level function is subdivided into smaller single functions or individual operations and allocated to single parts or sub-assemblies called modules. These modules are treated as individual components and have well-defined electrical or mechanical interfaces. These are then interfaced together to form the complete product to perform its complete function. Engineering products with modular architecture are more common than integral designs.

Integral

Integral product architecture is where the functions of the engineering product are carried out by a combination of parts that are not organized in a structured manner. Hence, the functional implementation is achieved by one or very few modules where components perform multiple functions.

Integral system-level design is often preferred when weight, shape, size & cost constraints affect and undermine the product’s performance. Design for manufacture and assembly, which emphasizes minimises parts, also counts as another strong driver of integral product architecture product designs. Generally, integral engineering products have a very high function-to-components ratio, meaning the product can perform multiple functions using the same components differently.

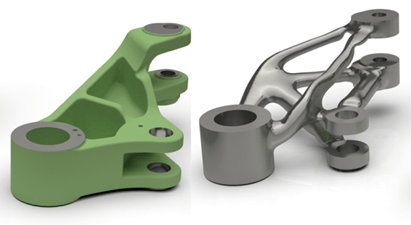

Design configuration

In design configuration, shape and general dimensions or sizes are established for the components defined in product architecture. It is mainly dependent on the three-dimensional constraints that define the envelope in which the product operates and the product architecture. This would be a preliminary selection of material, manufacturing process, modelling, sizing of parts etc.

Design configuration, sometimes called form, develops from its function and strongly depends on available materials and its manufacturing techniques.

The design configuration phase should involve the following steps;

- TRS or Product design specification (PDS) review

- Identify and define the space constraints

- Identify and define the interfaces and connections between the components

- Maintain functional independence of an assembly or the components to ensure that changes should affect only a single function

- Identify and eliminate or reduce parts by either removing them or combing a few parts together

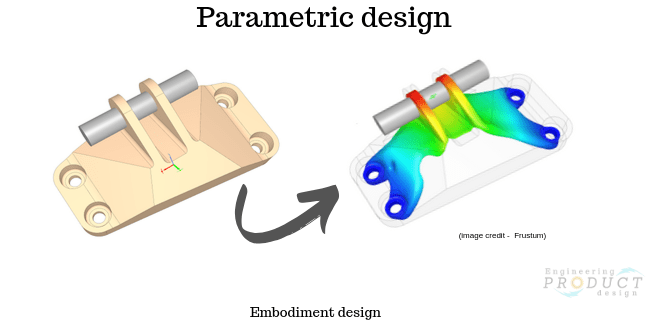

Parametric design

The main objective of the Parametric design is to allocate values to design variables to produce the best possible product design or functional component by considering both the technical and economic requirements. This design aspect is much more analytical than conceptual or design configuration.

The design variable is an attribute of a part whose value is under the designer’s control – these are typically dimension, tolerance, material, surface finish, heat treatment etc.

The main objective of parametric design is to set values for the design variables that will produce the best possible design considering both the performance and cost. Parametric design is also about setting the dimensions and tolerances to maximize quality and performance and minimize cost.

Steps would vary vastly depending on the nature of the product. But, for physical engineering products, product development could be divided into the following five steps.

- Parametric design problem formulation

- Alternative design generations

- Alternative design analysis

- Analysis of results evaluation

- Refining and optimisation

This is the stage of the design process where the design of a technical product is developed from the basic idea or concept per technical and economic standards up to the point where further detailed design can result in immediate production.

Three key stages of Embodiment design

- Product architecture

- Design configurations

- Parametric design

Detail design

During this stage of the design process, all of the individual parts’ arrangements, shapes, dimensions, and surface characteristics are finalised. Additionally, the materials are specified, production possibilities are evaluated, costs are estimated, and all drawings and other production documents are created. The detailed design phase results in a detailed final specification of every part and assembly in the form of production documentation such as part drawing, assembly drawing, bill of material and production procedure.

In the form of production documentation, the detailed design phase produces a detailed specification of each part and assembly.

What is a Detailed design phase?

In the Detailed design stage, the designing team completes the embodiment design and produces a detailed specification of each part and assembly. This includes final specifications and details of part shapes, forms, functions, dimensions, surface finish, and material options.

Therefore, Detailing design is the last step in Product Design Process (PDP), as shown in the image below, which starts the product design journey.

This activity creates all the required documentation so the production can be started.

Detailed design steps

Steps and stages within the detailed design changes depending on the type of product, type of new product development and the company setup. Typically detailed design steps could involve the following steps.

- Define Definitive layout

- Complete detailed drawings and OEM component specifications

- Integrate individual components into assemblies and create drawings and bill of materials (BOM).

- Complete production documents with production notes, assembly methods, transport and operating instructions.

- Check all documents for standards, completeness and correctness

- Release into production

Detailed design activities

You have got the design through most of the challenging parts. Now, it is time to get your product manufactured. Whether a pre-production small batch or large-scale batch production, getting the detailed design stage right is crucial in avoiding future problems during production.

Let us look at some of the key activities and decisions you must make during this phase.

Components selection and sizing

To carry out component selection and sizing during the detailed design stage, meticulously assess each required part for your product. Evaluate their functionality, compatibility, and manufacturing feasibility. Ensure that these components align with your design’s specifications and performance requirements. Determine precise dimensions and quantities needed. Consider materials, quality, and integration into the overall product assembly. Confirm that the selected components meet your product’s design criteria before advancing to manufacturing.

Make or buy decision

During this stage, you’ll make the “Make or Buy” decision by assessing whether to produce or purchase components internally. If you are a smaller company, it is cheaper to outsource most of the manufacturing to contract manufacturers.

Consider factors like workforce expertise, cost, time, and quality control. Evaluate if your resources align with in-house production or if external suppliers offer better efficiency. Decide based on what best suits your production capabilities and supports your business goals.

Detailed designs & engineering drawings

To complete Engineering Drawings during the detailed design stage, meticulously outline each aspect of your product’s design. Ensure precise representations of dimensions, materials, and assembly instructions. Use software or drafting tools for accuracy. Include detailed annotations to guide manufacturing. Verify these drawings align perfectly with your product’s specifications before moving to the manufacturing phase.

Bill of Materials

To complete the Bill of Materials (BOM) during the detailed design stage, meticulously list every component needed for your product. Detail materials, quantities, and specifications for each part. Ensure accuracy and alignment with the product design. Organise it in a structured format to guide procurement and manufacturing processes accurately. Double-check for completeness before moving ahead.

Revise the Product Design Specification

To revise the Product Design Specification (PDS) during the detailed design stage, begin by thoroughly reviewing the existing document outlining all aspects of your product’s design requirements, features, materials, dimensions, and performance criteria. Assess how well it aligns with initial specifications and any changes made during the design process. Incorporate feedback, improvements, or adjustments based on engineering analysis, testing results, and evolving customer needs. Ensure that the updated specification accurately reflects these modifications. It is a comprehensive guide for the subsequent manufacturing, assembly, and quality control phases, ensuring your product meets its intended objectives and standards.

Complete verification Prototype Testing

To complete verification Prototype Testing during the detailed design stage, meticulously conduct tests on your prototype. Validate its functionality, performance, and adherence to design specifications. Follow a comprehensive test plan, assessing every aspect. Record observations, identify any issues, and refine the design as needed. Ensure the prototype aligns perfectly with your intended product before proceeding to manufacturing.

Final Cost Estimate

To create a Final Cost Estimate during the detailed design stage, meticulously calculate materials, labour, and production expenses. Assess each component’s cost, considering quantities and suppliers. Factor in overheads and potential contingencies. Use detailed analysis and past data to ensure accuracy. Double-check calculations for a comprehensive understanding of the projected expenses before proceeding.

Prepare Design Project Report

Compile a comprehensive document outlining the entire design process to prepare a Design Project Report during the detailed design stage. Detail the project’s objectives, methodologies, and findings. Include design specifications, challenges faced, and solutions implemented. Present data, diagrams, and supporting evidence. Ensure clarity and coherence in explaining the design decisions and their impact on the final product.

Final Design Review

To conduct a Final Design Review during the detailed design stage, thoroughly assess every aspect of your product’s design. Evaluate if it meets specifications, functionality, and performance criteria. Review engineering drawings, test results, and documentation. Identify any discrepancies or areas needing improvement. Ensure alignment with project goals and client requirements before moving forward with manufacturing.

Release Design to Manufacturing

To release the Design to Manufacturing during the detailed design stage, ensure all design aspects are meticulously finalised and validated. Prepare comprehensive documentation, including finalised drawings, specifications, and test results. Coordinate with manufacturing teams, providing clear instructions and support. Verify that the design meets production capabilities and standards. Facilitate a smooth transition from design to manufacturing for efficient and accurate production.