In sand casting, molten metal is poured into an expendable sand mould cavity, where it solidifies to form the cavity shape part.

What is Sand Casting?

In sand casting, molten metal is poured into an expendable sand mould cavity by gravity or force, solidifying to form the cavity shape part. A 3D object formed by this process is also called casting. Most common sand castings include engine blocks and cylinder heads.

It is the most widely used metal casting manufacturing process accounting for a significant percentage of the total cast in weight. During the sand casting process, the material is heated to the correct temperature to melt and sometimes treated to modify the chemical composition to achieve the required material properties. Then the molten metal is poured into a mould with the desired shape cavity to cool down and solidify.

To produce the best quality sand castings at the lowest possible cost, the designers must carefully consider several process requirements and understand the limitation of sand casting. There are 8 key elements of sand casting, viz., draft angle, parting line, undercuts & cores, cross-sections, wall thickness, corners & angles, junction design, and casting allowance, that need to be taken into consideration to avoid the common pitfalls of mechanical engineers face during the sand casting process.

Defects or disadvantages will be an issue only if it affects the part’s functionality. So selecting a suitable manufacturing process is vital to satisfy the part functional requirement.

Characteristics of Sand casting

Sand casting is the most versatile among the manufacturing methods and gives engineers the freedom to design complex parts from an unlimited number of metals and alloys.

- Over 70% of all metal castings are produced via this process

- Sand casting can be produced in a wide range of sizes, from small statues to parts weighing over 100 tons

- Very complex parts can be produced easily and in one piece

- Low dimensional accuracy

- Poor surface finish

- Highly adaptable and could be used for handling mass production

How does the Sand casting process work?

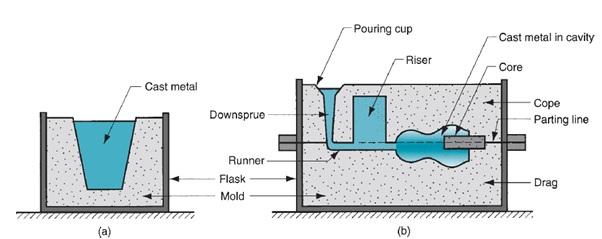

Elements of the gating system

Sand casting is one of the most common metal casting processes, and its mould is made of two halves. Two halves are contained inside a flask box, the upper half is called the cope, and the bottom half is called the drag. The image below shows that the flask is divided into two halves. The line that separates the two halves is called the parting line.

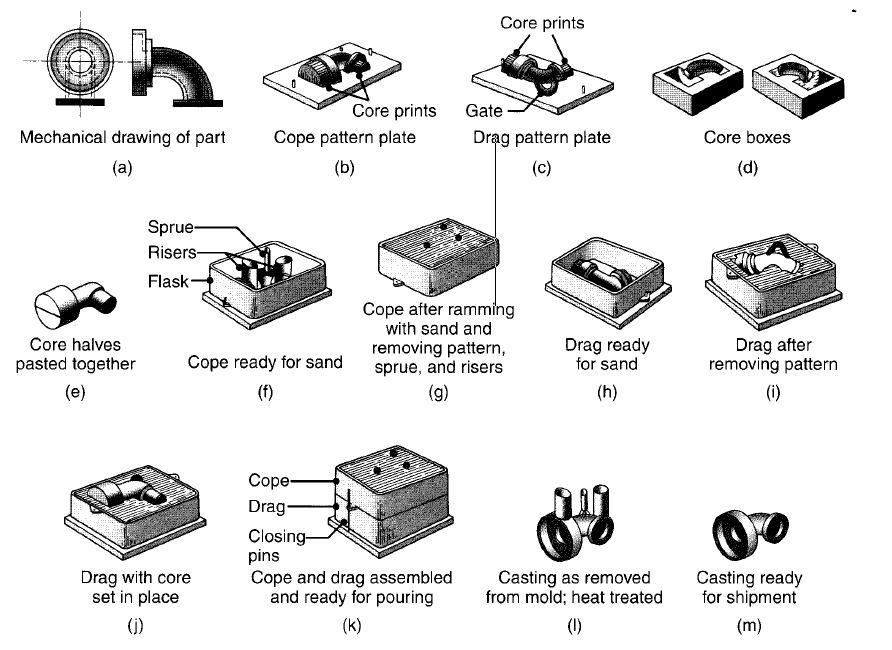

Sand casting steps

The following are the seven main steps of the sand-casting cycle

- Pattern-making step in which a replica of the object to be cast is made of suitable material. The pattern usually is oversized to allow for metal shrinkage during the cooling phase

- In the mould-making step, a sand mould is formed by packing sand into the mould around the pattern. The sand mould is divided into two halves, the top half is called the “Cope”, and the bottom is called the “Drag”. When the pattern is removed from the cavity, it forms remains for pouring the molten metal. Mould will have other features such as Sprue, runners, gate, pouring cup, riser etc., which will be discussed in detail later.

- The clamping step involves the two mould halves, Cope and Drag, securely clamped together, ready for pouring metal.

- Pouring molten metal is maintained at a set temperature. Molten metal is poured in quickly to avoid early solidification and

- Poured molten metal will begin to cool and solidify once inside the cavity. Most of the possible sand-casting defects are introduced at this solidification stage

- Once the cooling period elapses, the mould can be shaken out/broken off and casting

- Trimming involves cleaning and removing the section that is connected to the main part, such as the runner, Sprue etc

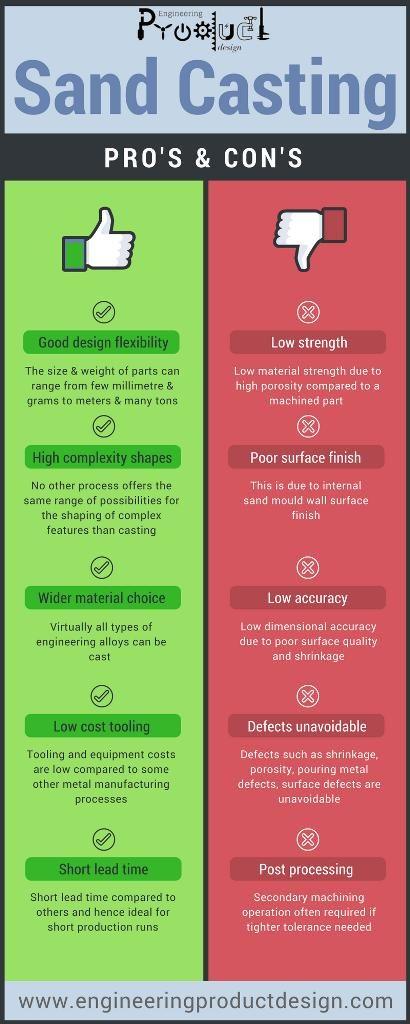

Advantages and disadvantages of sand casting

To understand any manufacturing process, first, careful consideration must be given not only to its advantages but, notably, to its potential limitations and process difficulties.

Advantages

- Design flexibility – The size and weight of parts can range from a few millimetres & grams to meters & many tons. The size and weight of the cast are only limited by the restriction imposed by molten metal handling and supply. Hence large parts can be produced.

- High-complexity shapes – No other process offers the same possibilities for shaping complex features as casting that produces near-net-shape components.

- Wider material choice – Virtually all engineering alloys can be cast as long as it can be melted.

- Low-cost tooling – Tooling and equipment costs are low compared to other metal manufacturing processes. Hence making it one of the cheapest methods to achieve near-net-shape components

- Short lead time – Short lead time compared to others is ideal for short production runs.

- Less waste – Scrap metal can be recycled

Disadvantages

- Low material strength – Parts have Low material strength due to high porosity compared to a machined part.

- Low dimensional accuracy – Shrinking and the surface finish dimensional accuracy is very poor.

- Poor surface finishes – Due to internal sand mould wall surface texture.

- Defects unavoidable – Like any other metallurgical process, defects or quality variations such as shrinkage, porosity, pouring metal defects, surface defects are unavoidable. Porosity is higher on sand casts than in other casting processes, such as Die casting and investment casting.

- Post-processing – Secondary machining operation is often required if tighter tolerance is needed to interface with other mating parts. Processing cost is high compared to tooling and material cost

- Higher risk – Safety hazards to humans and environmental problems

- Production issues – Removal of the pattern of the thin and small parts is challenging

Recommended reading

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth edition ed.). London: Pearson.