Injection moulding surface finish as per SPI and VDI classification systems – Gloss, semi-gloss, matte and textured surface finish.

What are Injection moulding surface finishes?

Injection moulding surface finish is critical to a successful part design and used for aesthetic and functional reasons in injection moulded parts for engineering products. The surface finish improves the look and the feel of a product as the perceived value and quality of the product increase with a suitable surface finish.

Many product designers would agree that the product’s aesthetic appeal heavily relies on the product’s look and how it feels in the consumer’s hands. As the image above shows, Apple has used the surface finish cleverly to place its smooth surface logo with the textured surrounding to good effect.

Detailed guide to Injection moulding

Why use surface finishes in injection moulding?

To increase part aesthetics

Part designers may use textures for a variety of aesthetic purposes. A smooth or matte surface texture improves its appearance and gives it a polished aspect. It also covers faults generated by injection mouldings, such as tool machining marks, sink marks, weld lines, flow lines, and shadow markings. Parts with excellent surface quality appeal more to customers from a business standpoint.

To improve part functionality

Aside from the aesthetic considerations that go into selecting an injection moulding surface finish, there are also important practical considerations.

The design may necessitate a firm grip for optimal functioning. Textured plastic finishes improve grip quality. Hence injection moulding surface treatments are frequently used on slip-resistant products. A textured mould can also aid in the escape of trapped gases.

A smooth SPI surface finish may cause the paint to peel off. However, a rough surface can ensure that the paint adheres better to the moulded item. A textured SPI surface treatment also increases the part’s strength and safety.

Texture has several advantages, including:

- Plastic flow creases—These creases may be removed by adding textured thickness while increasing strength and non-slip properties.

- Improved grip—Adding texture to the component makes handling easier, increasing usefulness and safety in specific applications.

- Paint adhesion—Paint adheres firmly to a textured object during subsequent moulding.

- Making undercuts—If you have a portion that will not consistently come over to the moving half of a mould, texturing on any surface may provide the necessary pull.

Injection mould tool surface finish specifications

The most common way to specify injection moulding surfaces is by using PIA (or SPI), VDI and Mold-tech standards. Injection mould toolmakers, manufacturers and design engineers worldwide recognise these three standards and PIA standards are marginally more common and widely known as “SPI grades“.

SPI Injection moulding surface finish

The Plastics Industry Association (PIA) is an independent US trade organisation formally known as SPI. Their surface finish standard for injection moulding tools is accepted across the industry. Hence the article is based on PIA standards.

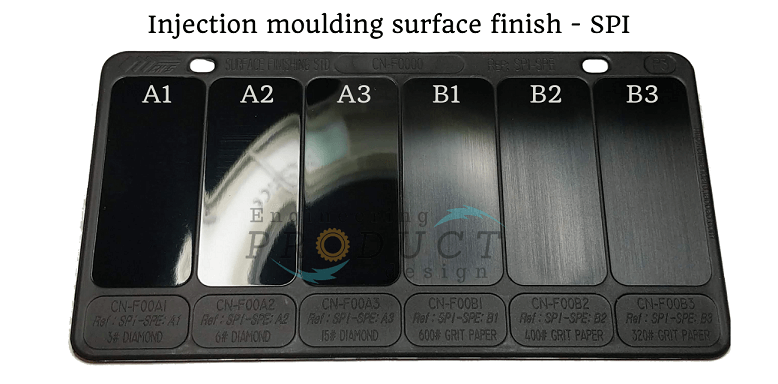

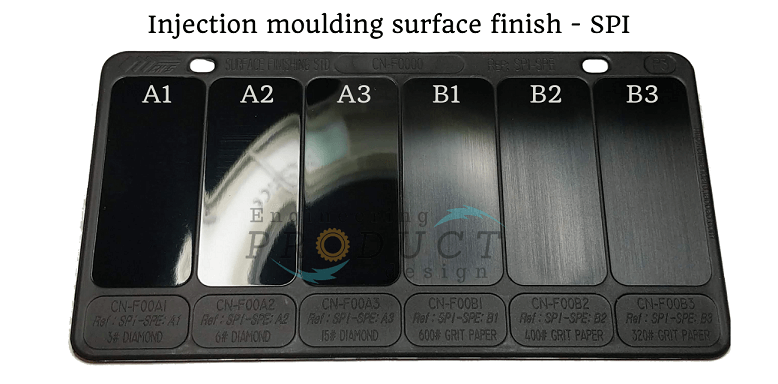

As per the PIA classification system, there are four major grades of surface finish, ranging from polished gloss (A1) to textured rough (D3) finish. Each category is then subdivided into three sets and has different requirements for allowable deviation from perfect, with lower numbers allowing for minor deviation and higher numbers allowing for more deviation.

Gloss finish – Grade A – Diamond finish

These grade “A” finishes are smooth, glossy, and the most expensive. These grades would need hardened tool steel moulds, which are buffed using various grades of diamond buff. Because of the fine-grain buffing paste and random directional rotary polishing method, it will not have a clear texture and scatter light rays, giving a very glossy finish. These are also called “Diamond finish” or “buff finish” or “A finish”.

| surface finish | SPI standard | Finishing method | Surface Roughness – Ra um (mil) | Cost of surface finish |

|---|---|---|---|---|

| Super High Glossy finish | A-1 | Grade #3, 6000 Grit Diamond Buff | 0.012 – 0.025 ( 0.5 – 1) | $ $ $ $ $ $ $ $ $ $ $ |

| High Glossy finish | A-2 | Grade #6, 3000 Grit Diamond Buff | 0.025 – 0.05 (1 – 2) | $ $ $ $ $ $ $ $ $ $ |

| Normal Glossy finish | A-3 | Grade #15, 1200 Grit Diamond Buff | 0.05 – 0.1 (2 – 4) | $ $ $ $ $ $ $ $ $ |

SPI gloss grades are suitable for products with a smooth surface finish for cosmetic and functional reasons. For example, A2 is the most common diamond finish used in the industry, resulting in good visually pleasing parts with a good release. In addition, grade “A” surface finishes are used on optical parts such as lenses, mirrors, and visors.

Semi-gloss finish – Grade B

These semi-gloss finishes are great for removing machining, moulding, and tooling marks with a reasonable tooling cost. These surface finishes are produced using different grades of sandpapers applied with linear motion, giving a linear pattern as shown in figure 2.

| Finish | SPI standard | Finishing Method | Cost |

|---|---|---|---|

| Fine Semi-glossy finish | B-1 | 600 Grit sandpaper paper | +++++++++ |

| Medium Semi-glossy finish | B-2 | 400 Grit sandpaper paper | ++++++++ |

| Normal Semi-glossy finish | B-3 | 320 Grit sandpaper paper | +++++++ |

SPI semi-gloss surface finishes would give a good visual appearance and remove mould tool marks. These are often used in parts that aren’t a decorative or visual important part of the product.

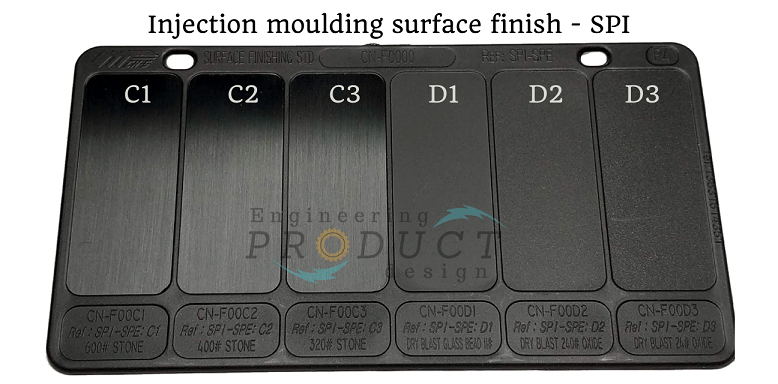

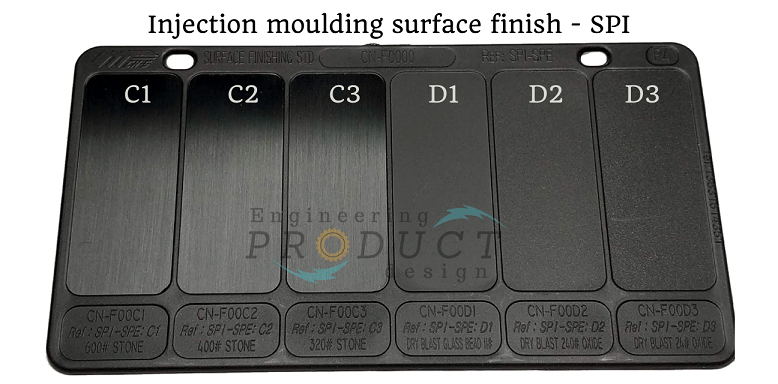

Matte finish – Grade C

These are the most economical and popular surface finishes, polished using fine stone powder. Sometimes called stone finish, it provides good release and helps hide machining marks. Grade C is also the first step of grades A and B surface finishes.

| Finish | SPI standard | Finishing Method | Cost |

|---|---|---|---|

| Fine Matte finish | C-1 | 600 Grit sanding stones | ++++++ |

| Medium Matte finish | C-2 | 400 Grit sanding stones | +++++ |

| Normal Matte finish | C-3 | 320 Grit sanding stones | ++++ |

Textured finish – Grade D

It gives the part a reasonable aesthetic visual appearance and is widely used in industrial parts and consumer goods. These are suitable for parts with no specific visual requirements.

| Finish | SPI standard | Medium | Cost |

|---|---|---|---|

| Satin Textured finish | D-1 | Dry Blast Glass Bead #11 pressure blasting | $ $ $ |

| Dull Textured finish | D-2 | Dry Blast #240 Oxide pressure blasting | $ $ |

| Rough Textured finish | D-3 | Dry Blast #24 Oxide pressure blasting | $ |

These textured finishes are first smoothened using fine stone powder and then dry blasted using aluminium oxide or glass beads—the random nature of the dry blasting results in a smooth and non-directional surface finish. A textured finish gives a good grip quality on the surface, hides deformations and marks, and even helps mask fingerprint smudges.

These textured surface finishes are used on thermoset industrial parts and are suitable for parts with a dull or satin textured finish, which helps grip such as the handle for consumer products.

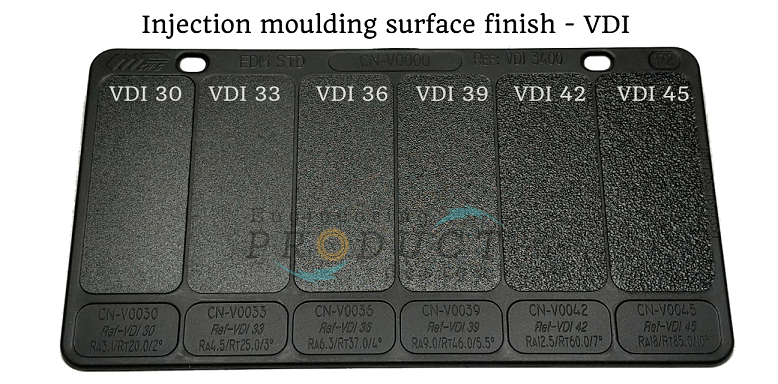

VDI Injection moulding surface finish

VDI surface finish refers to the Society of German Engineers’ mould texture standard and is widely utilised by tool producers worldwide, including North America, Europe, and Asia.

The VDI 3400 surface finish is mainly treated using Electrical Discharge Machining (EDM) when mould machining. However, it might also be accomplished using classic texturing techniques such as grit, stone and sandpaper.

| VDI Value | Description | Applications | Surface roughness (Ra) | |

|---|---|---|---|---|

| µm | µinch | |||

| 12 | 600 Stone | Low polish parts | 0.4 | 16 |

| 15 | 400 Stone | Low polish parts | 0.56 | 22 |

| 18 | Dry Blast Glass Bead | Satin finish | 0.8 | 31 |

| 21 | Dry Blast # 240 Oxide | Dull finish | 1.12 | 44 |

| 24 | Dry Blast # 240 Oxide | Dull finish | 1.6 | 63 |

| 27 | Dry Blast # 240 Oxide | Dull finish | 2.24 | 88 |

| 30 | Dry Blast # 24 Oxide | Dull finish | 3.15 | 124 |

| 33 | Dry Blast # 24 Oxide | Dull finish | 4.5 | 177 |

| 36 | Dry Blast # 24 Oxide | Dull finish | 6.3 | 248 |

| 39 | Dry Blast # 24 Oxide | Dull finish | 9 | 354 |

| 42 | Dry Blast # 24 Oxide | Dull finish | 12.5 | 492 |

| 45 | Dry Blast # 24 Oxide | Dull finish | 18 | 709 |

Mold-Tech Injection moulding surface texture

These are manufactured per Mold-Tech specifications, and they are formed by chemical etching or laser-based alteration of the mould cavity. Each one is denoted by an MT- followed by a five-digit code and are classified according to the serial number and texture depth.

| Mold-Tech A | ||

|---|---|---|

| Pattern # | Depth (mm) | Draft Angle (min) |

| MT-11000 | 0.01016 | 1˚ |

| MT-11010 | 0.0254 | 1.5˚ |

| MT-11020 | 0.0381 | 2.5˚ |

| MT-11030 | 0.0508 | 3˚ |

| MT-11040 | 0.0762 | 4.5˚ |

| MT-11050 | 0.1143 | 6.5˚ |

Mold-Tech is divided into four series: A, B, C, and D. Mold-Tech Series A finishes are most widely utilised on products because they include a spectrum of fine to coarse matte finishes that do not need a laser, masked chemical etching, or other designed texturing procedures

For example, MT-11010 has a sand-like appearance, MT-11120 has a smooth concrete appearance, MT-11555 has a wood panel appearance, and so on.

| Mold-Tech B | ||

|---|---|---|

| Pattern # | Depth (mm) | Draft Angle (min) |

| MT-11200 | 0.0762 | 4.5˚ |

| MT-11205 | 0.0635 | 4˚ |

| MT-11210 | 0.0889 | 5.5˚ |

| MT-11215 | 0.1143 | 6.5˚ |

| MT-11220 | 0.127 | 7.5˚ |

| MT-11225 | 0.1143 | 6.5˚ |

There are hundreds of Mold-Tech specs, aside from the previously mentioned sand, concrete, and wood textures, checkerboards, diamonds, straight or curved lines, and other patterns.

Because mould texturing contains coarser features than SPI finishes, a more aggressive draught angle is required; it is advised to add 1.5° of draught for every 0.001″ of texture depth.

How to choose a suitable injection moulding surface finish?

Choose injection moulding surface finishes by considering part function, the material used, and visual requirements. Most of the typical plastic injection moulded material can have a variety of surface finishes.

The surface finish selection must be established in the early embodiment design stage of the product design because the surface dictates material selection and the draft angle, influencing the tooling cost. For example, a course or textured finish needs a more significant draft angle so that the part can be ejected from the mould.

So what are the prime factors to consider when choosing the surface finish for injection moulding plastics?

Tooling cost

Surface finish and the material significantly influence the tool design and cost, so consider and evaluate the functionality in terms of surface early on the embodiment design. If the surface finish is critical to its functionality, consider the surface finish at the conceptual stages of the product design.

Many parts of the injection moulding process have been automated, but polishing is an exception. It is only the simplest of shapes that can be automatically polished. Polishers now have better equipment and materials to work with, but the process remains labour-intensive.

Draft angle

| Draft Angle (Degrees) | Surface Texture | |||

| DA-PA | DA-PC | DA-ABS | SPI Grade | VDI Grade |

| 0 | 1 | 0.5 | A | 12 |

| 0.5 | 1 | 0.5 | A | 15 |

| 0.5 | 1 | 0.5 | B | 18 |

| 0.5 | 1 | 0.5 | 21 | |

| 0.5 | 1.5 | 1 | 24 | |

| 1 | 2 | 1.5 | 27 | |

| 1.5 | 2 | 2 | 30 | |

| 2 | 3 | 2.5 | 33 | |

| 2.5 | 4 | 3 | 36 | |

| 3 | 5 | 4 | 39 | |

| 4 | 6 | 5 | 42 | |

| 5 | 7 | 6 | 45 | |

Mould tool material

The mould tool greatly influences the surface smoothness of the injection moulding. A mould may be made from various metals, although steel and aluminium are the most popular. The effects of these two metals on moulded plastic components are vastly different.

In general, hardened tool steel can produce smooth plastic finishes compared to aluminium alloy tools. Hence consider steel moulds if the pieces have an aesthetic function that requires a low level of surface roughness.

Moulding material

A wide range of injection moulding plastics is available to cover all sorts of parts and functions. However, not all plastics can achieve the same injection moulding surface finish. Some polymers are better suited to smooth finishes, while others are better suited to roughening up for a more textured surface.

Chemical and physical qualities differ between injection moulding materials. Melting temperature, for example, is a crucial factor in a material’s capacity to give a certain surface quality. Additives also have an impact on the outcome of a completed product. As a result, it is critical to evaluate the various materials before deciding on a surface texture.

Furthermore, material additives like filler and pigments might impact the surface finish of a moulded object. The tables in the next section illustrate the applicability of several injection moulding materials for various SPI finish designations.

Material suitability for Grade SPI-A surface finish

| Material | A-1 | A-2 | A-3 |

|---|---|---|---|

| ABS | Average | Average | Good |

| Polypropylene (PP) | Not recommended | Average | Average |

| Polystyrene (PS) | Average | Average | Good |

| HDPE | Not recommended | Average | Average |

| Nylon | Average | Average | Good |

| Polycarbonate (PC) | Average | Good | Excellent |

| Polyurethane (TPU) | Not recommended | Not recommended | Not recommended |

| Acrylic | Excellent | Excellent | Excellent |

Material suitability for Grade SPI-B surface finish

| Material | B-1 | B-2 | B-3 |

|---|---|---|---|

| ABS | Good | Good | Excellent |

| Polypropylene (PP) | Good | Good | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Good | Good | Excellent |

| Nylon | Good | Excellent | Excellent |

| Polycarbonate (PC) | Good | Good | Average |

| Polyurethane (TPU) | Not recommended | Average | Average |

| Acrylic | Good | Good | Good |

Material suitability for Grade SPI-C surface finish

| Material | C-1 | C-2 | C-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Excellent |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Excellent |

| Polycarbonate (PC) | Average | Not recommended | Not recommended |

| Polyurethane (TPU) | Good | Good | Good |

| Acrylic | Good | Good | Good |

Material suitability for Grade SPI-D surface finish

| Material | D-1 | D-2 | D-3 |

|---|---|---|---|

| ABS | Excellent | Excellent | Good |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Good |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Good |

| Polycarbonate (PC) | Excellent | Not recommended | Not recommended |

| Polyurethane (TPU) | Excellent | Excellent | Good |

| Acrylic | Average | Average | Average |

Moulding parameters

Surface finishes for injection moulded objects can be affected by injection speed, pressure and temperature. For example, a high melt temperature and quick injection speed can assist generate glossier injection moulding surface surfaces with fewer weld lines.

A quicker filling rate through mould cavities can also minimise weld line visibility. As a result, it enhances the overall look of plastic coatings. A smoother SPI surface finish is achieved by combining high mould and melt temperatures with fast injection speed.

Surface finish comparison

VDI is not the same as Mold-Tech, which is used in various ways, including hand-finishing, laser etching, and chemical etching with patterns. Some textures, however, may have near equivalencies, such as SPI D-3, VDI 33, and MT-11020, which all appear highly similar. In addition, VDI 12 and SPI C-1 are equal in many ways.

| VDI 3400 | ISO, VDI,ASA | ISO/TC 213 | SPI | ||

|---|---|---|---|---|---|

| Charmilles | Ra=CLA=AA | Rz | |||

| CH | µm | µinch | µm | ||

| – | 0.025 | 1 | N1 | A1 | |

| – | 0. 05 | 2 | N2 | A2 | |

| 0 | 0. l | 4 | N3 | A3 | |

| 1 | 0. 11 | 4.48 | |||

| 2 | 0. 12 | 5.04 | |||

| 3 | 0. 14 | 5.6 | |||

| 4 | 0. 16 | 6.4 | |||

| 5 | 0. 18 | 7.2 | |||

| 6 | 0. 2 | 8 | Bl | ||

| 7 | 0. 22 | 8.8 | N4 | B2 | |

| 8 | 0. 25 | 10 | |||

| 9 | 0. 28 | 11.2 | B3 | ||

| 10 | 0. 32 | 12.8 | |||

| 11 | 0. 35 | 14 | 1.5 | Cl | |

| 12 | 0.4 | 16 | N5 | ||

| 13 | 0. 45 | 18 | C2 | ||

| 14 | 0. 5 | 20 | |||

| 15 | 0. 56 | 22.4 | 2.4 | ||

| 16 | 0.63 | 25.4 | C3 | ||

| 17 | 0.7 | 28 | |||

| 18 | 0.8 | 32 | N6 | Dl | |

| 19 | 0.9 | 36 | |||

| 20 | 1 | 40 | D2 | ||

| 21 | 1.12 | 44.8 | 4. 7 | ||

| 22 | 1.26 | 50.4 | |||

| 23 | 1.4 | 56 | |||

| 24 | 1.62 | 64 | 6.5 | N7 | |

| 25 | 1.8 | 72 | |||

| 26 | 2 | 80 | |||

| 27 | 2.2 | 88 | 10 .5 | ||

| 28 | 2.5 | 100 | |||

| 29 | 2.8 | 112 | |||

| 30 | 3.2 | 128 | 12.5 | N8 | D3 |

| 31 | 3.5 | 140 | |||

| 32 | 4 | 160 | |||

| 33 | 4.5 | 180 | 17.5 | ||

| 34 | 5 | 200 | |||

| 35 | 5.6 | 224 | |||

| 36 | 6.3 | 252 | 24 | N9 | |

| 37 | 7 | 280 | |||

| 38 | 8 | 320 | |||

| 39 | 9 | 360 | 34 | ||

| 40 | 10 | 400 | |||

| 41 | 11.2 | 448 | |||

| 42 | 12.6 | 504 | 48 | N10 | |

| 43 | 14 | 560 | |||

| 44 | 16 | 640 | |||

| 45 | 18 | 760 | 69 | ||