Selecting a suitable material for injection moulded parts is one of the most important aspects of any engineering product design. Considering the injection moulding material selection at an early stage of product design is vital as it impacts both part functionality and tooling cost.

What is the Injection moulding process?

Injection moulding is a manufacturing process of producing plastic components. The process requires an injection moulding machine, mould, and raw material. The injection moulding machine melts the plastic, which cools inside the mould to take the shape of the finished product.

Plastic consumption has increased unprecedentedly in recent years due to the global demand for consumer products. This demand has driven companies to find new and advanced polymers to withstand any application and environment, resulting in thousands of plastics and more than 45 polymer families.

According to the mat web database, there are over 70000 Thermoplastics and 18000 Thermosets available to choose from, highlighting the challenges faced by engineering product designers.

Narrowing down this vast selection of injection moulding material options is an overwhelming task, so finding a starting point is essential. The following material guide lists some of the most commonly used injection moulded materials and their benefits and properties.

Types of plastic material for injection moulding

Acrylonitrile Butadiene Styrene (ABS)

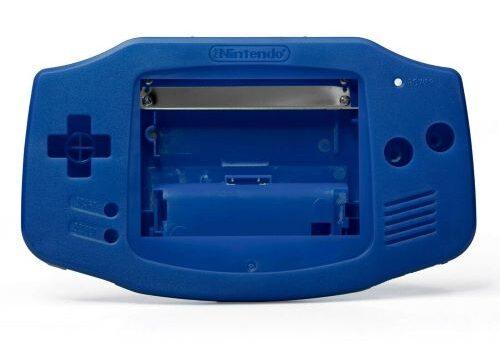

Due to its flexible and diversified qualities, ABS is one of the most widely used injection moulding materials for engineering products. ABS offers the right combination of mechanical toughness, chemical resistance, and electrical insulating properties across a wide range of temperatures.

ABS is an opaque amorphous thermoplastic with a glass transition temperature of 105 degrees Celsius. Carbon black and UV stabilizers can be added to the base ABS to modify to avoid UV degradation for outdoor products.

Its mechanical properties, ability to add additives to change the composition to withstand the various application environments, and ease of colour change make ABS an attractive injection moulding material for consumer electronics.

It can be easily machined, relatively cheap and widely recycled, making it ideal for rapid prototyping at various new product development stages.

Common ABS brands – Polylac, Cycolac, LG ABS, Elix, Lustran, Novodur, Kumho, Magnum and Gebabs

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| It offers good impact resistance, toughness, and rigidity | Low resistance against solvents |

| ABS surface is ideal for metal coatings | Vulnerable against outside harsh weather |

| Excellent appearance and processability | It has low dielectric strength |

| Good resistance against chemicals | Not suitable for high-temperature application |

Applications

- Handheld consumer devices

- Refrigerator vegetable boxes

- Large photocopier panels

- Interior and exterior automotive parts

- Electrical toys

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1020 – 1210 | Kg/m3 |

| Young Modulus | 1.79 – 3.20 | GPa |

| Elongation at Break | 10 – 50 | % |

| Elongation at Yield | 1.7 – 6 | % |

| Strength at Break (Tensile) | 29.8 – 43 | Mpa |

| Strength at Yield (Tensile) | 29.6 – 48 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 200 – 215 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 1.6 – 2.4 | GPa |

| Hardness Shore D | 100 – 100 | |

| Shrinkage | 0.7 – 1.6 | % |

| Glass Transition Temperature | 90 – 102 | °C |

| UV Light Resistance | Poor | |

| Gamma Radiation Resistance | Good | |

| Water Absorption 24 hours | 0.05 – 1.8 | % |

| Min. Continuous Service Temperature | -20 to -15 | °C |

| Max. Continuous Service Temperature | 86 to 89 | °C |

| Coefficient of Linear Thermal Expansion | 7 – 15 | 10-5 /°C |

Further reading

Polycarbonate (PC)

Polycarbonate is an amorphous transparent thermoplastic polymer with excellent impact strength. Because of transparency and inherent UV filtering properties, it is frequently used as a substitute for glass such as lenses but is vulnerable to scratching.

PC has exceptional mechanical properties and is highly suitable for moulding with tight tolerances. The compound has broad industrial and domestic applications.

They are less resistant to some solvents and petrochemical. The weather resistance of this polymer is not adequate, hence not recommended for outdoor applications without protective coatings, which will increase chemical and abrasion resistance.

PC is an excellent choice for injection moulding as it offers precise and predictable dimensional control in shrinkage.

Common Polycarbonate brands – Lexan Makrolon, Iupilon, Trirex, Lupoy, Carbotex and Ramtough

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Possesses high strength and impact resistance | Less resistant to solvents |

| Less flammable | Can crack in case of stress and susceptible to scratching |

| Dimensionally stable and able to keep tight moulding tolerances | Difficult to process because of the high temperature |

| It has good optical properties and a natural UV filter | It turns yellow if exposed to UV light for a long time without protection |

Applications

- Plastic eyewear lenses, CDs, and DVDs

- Automotive parts such as headlights

- Electrical insulators, connectors and lighting fixtures

- Medical use and mechanical equipment

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1140 – 1140 | Kg/m3 |

| Young Modulus | 2.20 – 2.50 | GPa |

| Elongation at Break | 50 – 120 | % |

| Elongation at Yield | 6.00 – 7.00 | % |

| Strength at Break (Tensile) | 55 – 77 | Mpa |

| Strength at Yield (Tensile) | 61 – 69 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 80 – 650 | J/m^2 |

| Flexibility-Stiffness (Flexural Modulus) | 2.2 – 2.5 | GPa |

| Hardness Shore D | 90 – 95 | |

| Shrinkage | 0.7 – 1.0 | % |

| Glass Transition Temperature | 160 – 200 | °C |

| UV Light Resistance | Fair | |

| Gamma Radiation Resistance | Good | |

| Water Absorption 24 hours | 0.1 – 0.2 | % |

| Min. Continuous Service Temperature | -60 to -50 | °C |

| Max. Continuous Service Temperature | 100 to 140 | °C |

| Coefficient of Linear Thermal Expansion | 7 – 9 | 10-5 /°C |

Further reading

Polycarbonate + Acrylonitrile Butadiene Styrene (PC/ABS)

Polycarbonate + acrylonitrile butadiene styrene (PC/ABS) is an engineering thermoplastic blend of PC and ABS. The properties of PC/ABS will depend on the ratio of the mix and any additives. PC/ABS is a high-impact engineering thermoplastic that is excellent for functional prototype and low-volume production.

PC/ABS, like ABS, can be easily coloured and modified using modifiers such as flame retardants and impact modifiers. In addition, additives such as UV stabilizers and easy mould releases improve material characteristics to meet application requirements.

Also, reinforcing agents such as glass fibres and mineral fillers will improve the material for demanding applications. PC/ABS resins are suitable for applications requiring high toughness across a wide temperature range up to 110°C.

Common PC/ABS brands – Cycoloy, Pulse, Mablex, Emerge and Bayblend

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Low overall shrinkage | Poor insulator (Low dielectric strength) |

| Provides high strength, stiffness, and heat resistance | Medium impact performance& low continuous service temperature |

| Offers high toughness and dimensional accuracy | Poor resistance against solvents |

| Printable and colourable | Low fatigue endurance |

| Easy processing | Poor resistance to outdoor weather exposure |

Applications

- Automotive components such as Glovebox, Knee bolsters, Blow moulded seatbacks.

- Consumer electronics devices such as TV frames, Adapters and chargers

- Mobile phone bodies and laptop monitors enclosures

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1100 – 1150 | Kg/m3 |

| Young Modulus | 2.00 – 2.20 | GPa |

| Elongation at Break | 60 – 85 | % |

| Elongation at Yield | 3.00 – 5.00 | % |

| Strength at Break (Tensile) | 40 – 50 | Mpa |

| Strength at Yield (Tensile) | 45 -55 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 400 – 600 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 2.0 – 2.3 | GPa |

| Hardness Shore D | 85 – 90 | |

| Shrinkage | 0.5 -0.7 | % |

| Glass Transition Temperature | 125 | °C |

| UV Light Resistance | Fair | |

| Gamma Radiation Resistance | Good | |

| Water Absorption 24 hours | 0.2 – 0.3 | % |

| Min. Continuous Service Temperature | -50 to -40 | °C |

| Max. Continuous Service Temperature | 70 to 110 | °C |

| Coefficient of Linear Thermal Expansion | 4 – 5 | 10-5 /°C |

Further reading

High Impact Polystyrene (HIPS)

High impact polystyrene, widely known as HIPS, is an amorphous thermoplastic made from general-purpose polystyrene (GPPS) by adding rubber to increase its impact resistance and durability. Easy forming and properties such as low cost, high impact strength, and low density make HIPS ideal for model making applications.

Due to its high pliable properties induced by the rubber, HIPS are widely vacuum formed. Although it is suited and commonly associated with vacuum or thermoforming, it is also an ideal material for injection moulding, especially for small parts in large quantities with high-level details.

Common HIPS brands – Ultratuf, Styron and Orfitrans™ Stiff

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Exceptional thermoforming properties | Highly flammable |

| A recyclable and versatile material | Poor resistance against organic solvents |

| Good rigidity and dimensional stability | Recyclable, but uneconomical if recycled |

| Cost-effective | |

| High impact strength | |

| Lower surface friction |

Applications

- Used to make sports equipment and signage

- Food packaging such as disposable trays, coffee cups and yoghurt cups.

- Ideal material for creating ID cards

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1030 – 1060 | Kg/m3 |

| Young Modulus | 1.5 – 3.0 | GPa |

| Elongation at Break | 10.00 – 50.00 | % |

| Elongation at Yield | 1.00 – 2.10 | % |

| Strength at Break (Tensile) | 20 – 45 | Mpa |

| Strength at Yield (Tensile) | 20 – 40 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 50 – 350 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 1.5 – 3 | GPa |

| Hardness Shore D | 60 – 75 | |

| Shrinkage | 0.2 – 0.80 | % |

| Glass Transition Temperature | 88 – 92 | °C |

| UV Light Resistance | Poor | |

| Gamma Radiation Resistance | Poor | |

| Water Absorption 24 hours | 0.05 – 0.15 | % |

| Min. Continuous Service Temperature | 60 to 80 | °C |

| Max. Continuous Service Temperature | -40 to-20 | °C |

| Coefficient of Linear Thermal Expansion | 5 – 20 | 10-5 /°C |

Further reading

- https://www.polymershapes.com/product/high-impact-polystyrene-hips/

- https://advancedplastiform.com/materials/hips/

- https://www.curbellplastics.com/Research-Solutions/Materials/High-Impact-Polystyrene

- https://www.polymershapes.com/product/high-impact-polystyrene-hips/

- https://www.eagleplastics.co.uk/what-is-high-impact-polystyrene-used-for/

Polyphthalamide (PPA)

Polyphthalamide, also known as PPA, is a high heat resistance polyamide. Compared to common polyamide types (PA6, PA66, PA11, PA12, PA46), it has very low moisture absorbent and excels in extreme temperature and chemical environments.

PPA is an excellent choice for metal replacement parts and parts with demanding requirements. PPA bridges the performance gap between nylons and polyesters and higher-priced, high-temperature materials such as PEI and PEEK.

Common PPA brands – Rilsan, Fortii, Amodel, Verton, Grivory, Zytel

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Good dimensional stability and impact strength | Sensitive to powerful oxidants, mineral acids, acetic acid and formic acid |

| Very low creep tendency & water absorption | Not flame-resistant |

| Good heat, chemical and fatigue resistance | Requires high processing temperatures |

| Good impact strength | Special drying equipment required |

| Good chemical, heat and fatigue resistance | Higher cost compared to other common materials |

| High stiffness and strength compared to Nylon |

Applications

- Used for electrical connectors for high temperature

- Extensive use in the automotive industry

- Used to make combs, bearings, and spools

- Used in cameras, structural parts

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1110 – 1200 | Kg/m3 |

| Young Modulus | 3.7 – 3.7 | GPa |

| Elongation at Break | 2.60 – 3.0 | % |

| Elongation at Yield | 6.0 – 6.0 | % |

| Strength at Break (Tensile) | 80 – 90 | Mpa |

| Strength at Yield (Tensile) | 80 – 90 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 960 – 1065 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 2.1 – 3.7 | GPa |

| Hardness Shore D | 60 – 95 | |

| Shrinkage | 1.50 – 2.20 | % |

| Glass Transition Temperature | 55 – 58 | °C |

| UV Light Resistance | Poor | |

| Gamma Radiation Resistance | Fair | |

| Water Absorption 24 hours | 0.36 – 0.75 | % |

| Min. Continuous Service Temperature | -40 to -20 | °C |

| Max. Continuous Service Temperature | 60 to 80 | °C |

| Coefficient of Linear Thermal Expansion | 5 – 6 | 10-5 /°C |

Polymethyl Methacrylate Acrylic (PMMA)

Polymethyl Methacrylate Acrylic, also known as Acrylic, is an amorphous transparent thermoplastic widely used as a glass replacement. Compared to other transparent polymers such as PC and Polystyrene, PMMA has a higher resistance to UV light, good weathering properties and superior light transmission.

When tensile strength, flexural strength, transparency, polishability, and UV tolerance are essential than impact strength, chemical resistance, and heat resistance, PMMA is a cost-effective alternative to polycarbonate (PC).

PMMA is also 100% recyclable, biocompatible and non-biodegradable. Acrylic also can cope well with design without excessive shrinking or sinking due to irregular wall thicknesses. They are widely used to make light pipes, lenses, light shades, optical fibres and signs.

Common PMMA brands – Crylux, Plexiglas, Acrylite, Perspex

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Offer extraordinary optical clarity | Susceptible to organic solvents |

| Suitable for outdoor applications | Cracks under stress |

| Excellent scratch resistance compared with other polymers | Melts easily |

| Offer sound transmission of light | Absorbs moisture |

| Tough, durable and light | Poor impact resistance |

| High resistance to UV light | Low heat resistance (70oC – 90oC) |

Applications

- Transparent parts of automobiles like head and rear lenses

- Covering of household lights

- Used in making decorative materials

- Used in Manufacturing safety materials and shields

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1170 – 1200 | Kg/m3 |

| Young Modulus | 2.5 – 3.5 | GPa |

| Elongation at Break | 2.0 – 10.0 | % |

| Elongation at Yield | 2.0 – 10.0 | % |

| Strength at Break (Tensile) | 38 – 70 | Mpa |

| Strength at Yield (Tensile) | 38 – 70 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 10.0 – 25.0 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 2.5 – 3.5 | GPa |

| Hardness Shore D | 90 – 99 | |

| Shrinkage | 0.2 – 0.8 | % |

| Glass Transition Temperature | 90 – 110 | °C |

| UV Light Resistance | Good | |

| Gamma Radiation Resistance | Good | |

| Water Absorption 24 hours | 0.1 – 0.4 | % |

| Min. Continuous Service Temperature | -40 to -30 | °C |

| Max. Continuous Service Temperature | 70 to 90 | °C |

| Coefficient of Linear Thermal Expansion | 5 – 9 | 10-5 /°C |

Further reading

- PMMA or Acrylic: Guide to Support Your Future ‘Transparent’ Developments

- PMMA plastic injection molding

High-Density Polyethylene (HDPE)

HDPE is a thermoplastic polymer with a linear structure and strong intermolecular forces, resulting in higher tensile strength compared to LDPE. Due to its high strength to density ratio, HDPE is used in a wide variety of applications, including corrosion-resistant pipelines, shampoo bottles, plastic lumber, plastic bottles, and cutting boards.

They are light, have high toughness, strong chemical resistance, impermeability, and electrical insulating properties, making them one of the most versatile injection moulding materials available. Carbon black or UV additives will increase weather resistance.

Common HDPE brands – Marlex, Sabic, DOW and LG

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Low cost and good processability | Susceptible to stress cracking |

| Good impact resistance across a wide temperature range (-40oC to 90oC) | Thermal expansion is high |

| FDA compliant and low water absorption | Flammable |

| Easily Recycled | Poor temperature resistance |

| Excellent resistance to solvents | Weather resistance is almost none |

| Good low-temperature resistance | High thermal expansion |

Application

- Excessive use in household usage

- Used to make insulators for cables

- Usage in Electronics and consumer products

- Making of medical products

Properties

| Property | Value | Units |

|---|---|---|

| Density | 940 – 970 | Kg/m3 |

| Young Modulus | 0.5 – 1.1 | GPa |

| Elongation at Break | 500 – 700 | % |

| Elongation at Yield | 15.0 – 15.0 | % |

| Strength at Break (Tensile) | 30 – 40 | Mpa |

| Strength at Yield (Tensile) | 25 – 30 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 20 – 220 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 0.75 – 1.575 | GPa |

| Hardness Shore D | 60 – 70 | |

| Shrinkage | 1.5 – 4.0 | % |

| Glass Transition Temperature | -110 | °C |

| UV Light Resistance | Poor | |

| Gamma Radiation Resistance | Fair | |

| Water Absorption 24 hours | 0.005 – 0.01 | % |

| Min. Continuous Service Temperature | -70 to -60 | °C |

| Max. Continuous Service Temperature | 100 to 120 | °C |

| Coefficient of Linear Thermal Expansion | 6 – 11 | 10-5 /°C |

Further reading

Low-Density Polyethylene (LDPE)

Low-density polyethylene is a semi-rigid and translucent polymer which belongs to the polyethylene family of thermoplastics.

The wide range of properties of low-density polyethylene, such as soft, light, tough, and flexible making it an ideal choice for making containers, plastic bags, water pipes, and dispensing bottles. Plastic bags are the most common.

When subjected to stress, it can undergo permanent deformation; thus, making it not suitable for high-stress applications. LDPE also possess good electrical insulating properties and low water absorption but is very poor.

The ACC reports that LDPE has excellent resistance to acids, bases and vegetable oils. Its toughness, flexibility and relative transparency make it a good choice for packaging applications requiring heat-sealing.

Common LDPE brands – ExxonMobile, Nexxstar & Escorene Ultra

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Excellent electrical insulating properties | Low strength and stiffness |

| Low cost with easy processability | Vulnerable to stress cracking |

| Low moisture absorption | Highly flammable material |

| FDA graded material | Shows high thermal expansion |

| High impact strength at low temperature | Lower maximum service temperature |

| Excellent optical properties | Poor UV resistance |

Applications

- Used to make diversified households

- Used to make insulators for cables

- Electronics products carry frequent use of this material

- In the production of medical-related products

Properties

| Property | Value | Units |

|---|---|---|

| Density | 917 – 940 | Kg/m3 |

| Young Modulus | 0.13 – 0.3 | GPa |

| Elongation at Break | 200 – 600 | % |

| Elongation at Yield | 13.0 – 17.5 | % |

| Strength at Break (Tensile) | 10 – 20 | Mpa |

| Strength at Yield (Tensile) | 10 – 20 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 999 – 999 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 0.245 – 0.335 | GPa |

| Hardness Shore D | 40 – 50 | |

| Shrinkage | 2.0 – 4.0 | % |

| Glass Transition Temperature | -110 | °C |

| UV Light Resistance | Fair | |

| Gamma Radiation Resistance | Fair | |

| Water Absorption 24 hours | 0.005 – 0.015 | % |

| Min. Continuous Service Temperature | -70 to – 60 | °C |

| Max. Continuous Service Temperature | 80 to 90 | °C |

| Coefficient of Linear Thermal Expansion | 10.0 – 20 | 10-5 /°C |

Further reading

Polypropylene (PP)

Polypropylene is a semi-crystalline light-weight thermoplastic and is one of the top three injection moulding material polymers used today to make varied products such as carpets, reusable water bottles and toys. It can be either homopolymers or copolymers with identical properties. They are tough and rigid and amongst the cheapest and lightest polymers available.

PP retains its mechanical and electrical properties even at elevated temperatures and in humid conditions. PP is also good at repelling water. Additives such as clarifiers, glass fibres, flame retardants, minerals, lubricants, conductive fillers, and pigments can improve physical and mechanical properties. Polypropylene has an identification code of 5 and is 100% recyclable.

Common polypropylene brands – Xyron, Ultrafuse, Torayca

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Offer the best resistance against moisture | Erode if exposed to UV light |

| Better used as a food Graded material | Highly flammable |

| Excellent impact strength of the material | Affected by chlorinated hydrocarbons & solvents |

| Good resistance to environmental stress cracking and steam sterilization | Poor resistance to impact and scratches easily |

| Additives will improve properties | Become brittle below -20 oC |

| 100% recyclable | Extremely sensitive to highly oxidizing acids |

Application

- Polypropylene is used both as plastic and fibre.

- Used in packaging material

- Polypropylene fibres used in carpets

- Making everyday usage products

- Used in the automobile industry

- Electrical components

Properties

| Property | Value | Units |

|---|---|---|

| Density | 900 – 910 | Kg/m3 |

| Young Modulus | 1.0 – 1.2 | GPa |

| Elongation at Break | 200 – 500 | % |

| Elongation at Yield | 6.00 – 250.0 | % |

| Strength at Break (Tensile) | 30 – 35 | Mpa |

| Strength at Yield (Tensile) | 20 – 35 | Mpa |

| Toughness (Notched Izod Impact at Room Temperature) | 60 – 500 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 1.0 – 1.4 | GPa |

| Hardness Shore D | 70 – 80 | |

| Shrinkage | 2.0 – 3.0 | % |

| Glass Transition Temperature | -20 | °C |

| UV Light Resistance | Fair | |

| Gamma Radiation Resistance | Poor | |

| Water Absorption 24 hours | 0.01 – 0.1 | % |

| Min. Continuous Service Temperature | -20 to -10 | °C |

| Max. Continuous Service Temperature | 100 to 130 | °C |

| Coefficient of Linear Thermal Expansion | 7.0 – 17.0 | 10-5 /°C |

Further reading

Polyoxymethylene (POM)

Polyoxymethylene, commonly known as Polyacetal or Acetal, is a semi-crystalline thermoplastic widely used for high precision engineering parts due to its high lubricity, excellent dimensional stability, good chemical resistance, and higher fatigue strength.

POM has excellent mechanical properties across a wide range of temperatures ( -40oC to +140oC), such as high toughness, rigidity and tensile strength and low creep compared to some other plastic materials. Because of the above properties, Acetal is used as a metal alternative in engineering product design. Although they withstand a wide temperature range, it is worth noting that they are brittle at low temperatures and outgas at higher temperatures.

The use of this plastic material depends upon its grades; some of them are perfect for injection moulding, while some are not suitable.

Some grades of Acetal are also widely used in additive manufacturing due to their high lubricity, which makes them ideal for parts that are difficult to release.

Common Acetal brands – Delrin, Tecaform, Acetron and EMI

Benefits and Limitations

| Benefits | Limitations |

|---|---|

| Wide temperature range -40oC to 140oC | Poor resistance to strong acids, bases, and UV radiation |

| Excellent mechanical properties across wide temperature range – High toughness, tensile strength, and rigidity | Sensitive to the oxidising agents |

| High Impact resistance & dimensional stability | Mould shrinkage too high |

| Provides excellent solvent, chemical and wear resistance – except for phenols | Difficult to bond due to its low surface energy without any surface treatment |

| Glossy and low friction surface finish | Flammable without any flame retardants due to high level of oxygen content |

| Very low creep and good resistance to environmental stress cracking | The processing temperature range is limited |

| Additives change the properties to suit the application | Poor thermal stability without suitable stabilizer system |

Applications

- Extensive use in the automotive industry

- Diversified applications in the making of everyday products

- Mechanical components like bearings and cams

- Limited role in the aviation industry

Properties

| Property | Value | Units |

|---|---|---|

| Density | 1410 – 1420 | Kg/m3 |

| Young Modulus | 2.8 – 3.7 | GPa |

| Elongation at Break | 15.0 – 75.0 | % |

| Elongation at Yield | 8.0 – 23.0 | % |

| Strength at Break (Tensile) | 60 – 70 | MPa |

| Yield Strength a (Tensile) | 54 -78 | MPa |

| Toughness (Notched Izod Impact at Room Temperature) | 60 – 120 | J/m2 |

| Flexibility-Stiffness (Flexural Modulus) | 2.8 – 3.7 | GPa |

| Hardness Shore D | 80 – 95 | |

| Shrinkage | 1.8 – 2.5 | % |

| Glass Transition Temperature | -60 to -50 | °C |

| UV Light Resistance | Poor | |

| Gamma Radiation Resistance | Fair | |

| Water Absorption 24 hours | 0.1 – 0.5 | % |

| Min. Continuous Service Temperature | -40 to -30 | °C |

| Max. Continuous Service Temperature | 80 to 140 | °C |

| Coefficient of Linear Thermal Expansion | 10.0 – 15.0 | 10-5 /°C |

Further reading