Engineering product design combines creativeness, technical design skills, engineering science and analysis to create products to satisfy the functional requirements of an end-user.

Contents covered in this article

What is Engineering Product Design?

Engineering Product design is a systematic and creative process of conceiving, developing, and optimising products that cater to specific market demands. Engineering product designers combine creativity, technical design, engineering principles, and analysis to create products that satisfy the functional requirements of an end user. They use various disciplines, methodologies, and technologies to transform ideas into practical, user-friendly products.

Evolution of Engineering product design

The evolution of engineering product design mirrors technological advancements and changing consumer needs. The history of the telephone is a prime example of how technology has driven the design of phones and mobiles.

From classic landlines to modern smartphones, the journey has been marked by a shift towards user-centric approaches, interdisciplinary team collaborations, and technological advancements.

The nature of product design and development within engineering companies has changed dramatically over the last few decades as products have become more multifaceted and the engineering supply chain has become more global. The knowledge embedded in modern products, such as smartphones, smartwatches & headphones, has grown dramatically because of easy access to digital information. Products such as smart speakers with multiple microphones, Phones with numerous cameras and consumer electronics with built-in NFC are revolutionising the technology industry. Due to the growth in consumer electronics and electric cars, the demand for primary and secondary battery technologies has soared, driving knowledge growth.

Modern Engineering Product Design challenges

In today’s fast-paced world, engineers face multifaceted challenges. These encompass stringent sustainability standards, complex technology integration, supply chain issues, shorter product lifecycles, and balancing innovation and cost-effectiveness.

Engineering product design and technological advancements in every field constantly change and evolve. Consumers seek more than functional products. They want it to look good, last longer, be in trend and cost less. The list is endless. For example, such computing power and miniaturisation advances have made the products smarter.

Engineering product design is changing as people seek more than functional products. They want it to look good, last longer, be in trend and cost less. The list is endless, constantly changing and evolving, along with technological advancements in every field. For example, such computing power and miniaturisation advances have made the products smarter.

For example, a few decades ago, you wouldn’t dream of dropping your phone in water. Still, people expect their phones to work and take pictures while they get soaked in the rain.

Due to the rapid speed of modern technology, the time to market is also getting shorter. Compressing the design cycle and making it work the first time. Companies and manufacturers’ success depends on how quickly they can design, manufacture and launch a trending product and how good it would be compared to their rivals.

From an engineer’s perspective, the change in product design has resulted in a fusion of mechanical, electrical, electronics and software disciplines. Differences between industrial design and mechanical products are diminishing. This has forced interdisciplinary engineers to work across teams, find more efficient ways to work and collaborate, and have the knowledge of other streams to help understand how a product comes together. Hence, you see many new design management processes, project management techniques, and design methodologies to streamline product development across teams.

Engineering product designers have to adapt to these trends and challenges. Gone are the days when special skills for life where you learn one skill and use it forever. These days, product design engineers need to constantly learn new skills. New materials, manufacturing processes, and surface finish must be researched and considered for every product designed to give the end user the best possible experience.

Although the challenges are high, there has never been a better time to be an engineering product designer.

Components of Engineering Product Design

Engineering Product designs are complex and cover a range of disciplines. It combines mechanical engineering, industrial designing, electrical engineering, and software expertise. This intricate collaboration fuels innovation, crafting products that seamlessly integrate form, function, and technology, embodying the collective effort of diverse teams. The critical components of engineering products can be grouped into the following fields and expertise.

- Mechanical design

- Industrial design

- Electrical and Electronics design

- Software Engineering

Mechanical Design

Mechanical design forms the backbone of countless engineering products, providing the foundation for their functionality and reliability. This engineering aspect involves crafting physical components and systems seamlessly integrating into the final product. It amalgamates precision, innovation, and practicality, incorporating specialised skills and knowledge.

At its core, mechanical design ensures products’ structural integrity, functionality, and efficiency. With a wealth of engineering knowledge and analysis capabilities, mechanical engineers bring concepts to life by harnessing CAD proficiency, simulation tools, and finite element analysis (FEA). This expertise allows them to optimise designs, fine-tuning every aspect for maximum performance.

Consider a classic example: the evolution of automobile engines. Mechanical design principles underpin the transformation from simple combustion engines to complex hybrid systems. Engineers leverage their proficiency in material selection, manufacturing techniques, and tolerance analysis to enhance efficiency while reducing environmental impact.

Furthermore, prototyping, testing, and understanding mechanical systems are integral to this process. Engineers delve deep into material properties and their implications on design and functionality, ensuring products meet stringent quality standards.

Mechanical design is the cornerstone of innovation, seamlessly blending engineering theory with practical application to shape the world’s most groundbreaking products.

Industrial Design

Industrial design breathes life and allure into engineering product design, focusing on creations’ aesthetics and user-centric aspects. It’s the art of harmonising form, function, and user experience to craft visually captivating and ergonomically sound products.

At its core, industrial design revolves around a user-centric approach. Designers immerse themselves in understanding user needs and behaviours, employing human factors and ergonomic principles to create products that seamlessly integrating into users’ lives. Factors like ease of use, comfort, and intuitive interaction take precedence.

This process often begins with sketching and visualisation, where concepts are brought to life on paper, evolving into detailed 3D models using sophisticated software. Designers weave their expertise in material and manufacturing knowledge into these models, ensuring that the chosen materials not only enhance aesthetics but also align with production feasibility.

Consider iconic examples like the iPhone, where industrial design merges sleek aesthetics with intuitive user interfaces. The curves, material selections, and overall form factor are meticulously crafted to enhance user experience while being visually striking.

In essence, industrial design is the bridge between functionality and aesthetics. It transforms engineering marvels into products that captivate, engage, and seamlessly integrate into users’ lives, embodying the perfect marriage of art and engineering.

Electrical and Electronics design

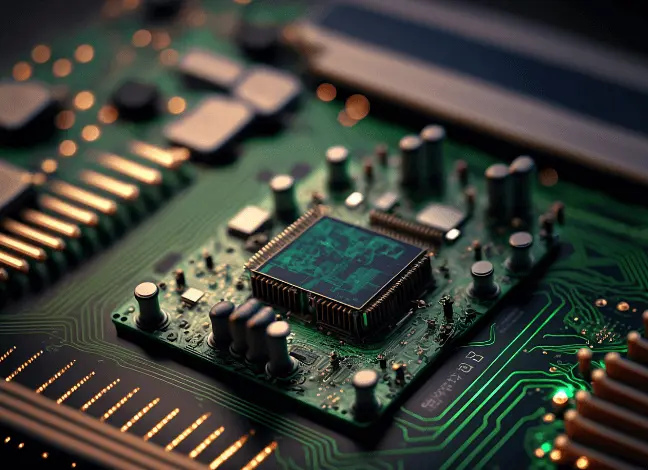

In our interconnected world, the realm of engineering product design finds its pulse in electrical and electronic design. This vital domain is the cornerstone of integrating electronic components, circuitry, and systems into products, enabling a spectrum of functionalities from automation to seamless connectivity and intelligent features.

Central to this domain is circuit design and analysis, where engineers craft intricate systems that govern a product’s functionality. Embedded systems and microcontrollers serve as the brains behind automated processes. At the same time, PCB design orchestrates the physical arrangement of electronic components, optimising space and performance.

Consider the evolution of smartphones. Their capabilities, from multitasking to high-resolution cameras, are indebted to analogue and digital signal processing. Moreover, ensuring electromagnetic compatibility (EMC) and signal integrity guarantees that devices function reliably without interference.

In microelectronics and VLSI design, engineers shrink complex functionalities into tiny chips. At the same time, knowledge of power and control systems ensures efficient energy usage and regulated functionality.

The synthesis of these elements defines our modern tech landscape, where electrical and electronic design propels engineering products toward innovation, connectivity, and functionality, shaping the devices that empower our daily lives.

Software Engineering

Software engineering emerges as the conductor in engineering product design, tying functionalities, interfaces, and connectivity together. Product design is given vitality by an unseen force that balances software architecture, user experience (UX) design, and skilled coding to guarantee smooth integration and functioning.

Fundamentally, software design requires programming expertise in various languages, including Python, C/C++, and Java, according to the requirements of the product. Developing embedded systems enhances things even more by permitting intelligence and independence. From conception to deployment, engineers are guided by the software development life cycle (SDLC), which serves as the roadmap.

The development of smart home devices and their intuitive interfaces are examples of skilful user interface (UI) and user experience (UX) design. Furthermore, breakthroughs that changed sectors were born from the union of cloud computing, IoT integration, and database administration.

Mobile applications, which provide features at the user’s fingertips, are a prime example of merging software design with usability. They are the perfect example of how engineering expertise and user-centric design can work together, from effective task management to seamless communication.

The backbone of digital engineering goods, software design fosters innovation, connectivity, and user-centred experiences that characterise our technologically advanced world.

For comprehensive product development, these disciplines must combine. Interdisciplinary fusion makes Comprehensive problem-solving possible, which tackles issues that call for knowledge from multiple fields.

Types of Product design

Engineering product design is done for various purposes and in various ways resulting in different product design types.

Engineering products are designed for various purposes, resulting in different product design types. Therefore, the product design could have a wide degree of uniqueness, ranging from an original idea like the wheel invention to constantly redesigning vehicles and phones.

The majority of product design activities are changes and variations on existing designs. However, changing an existing design doesn’t mean that the product design journey is less challenging for the company or the engineering designers.

From a product planning and development point of view, a company would have to consider the product design type they are venturing into to calculate the cost and resources they would need for their new product development.

Let us look into the four major product design types;

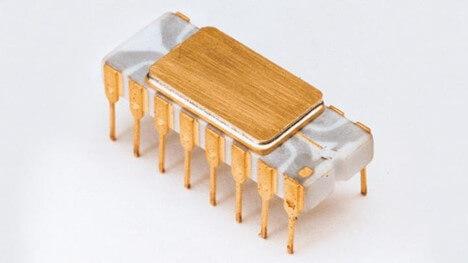

Original product design

The original design method or form is at the top of the spectrum. It satisfies a demand by utilising an original, inventive idea. Sometimes, but very rarely, the need itself is unique. Therefore, unique design requires inventiveness. Successful unique ideas are uncommon, but when they do emerge, they typically disrupt established markets because they include the seeds of new technology with far-reaching implications. One such innovative invention was the world’s first microprocessor, Intel 4004.

There are two different cases of the original design;

- An innovative, original design driven by the latest scientific discoveries and technological advancements.

- An original product that combines existing solutions in a different embodiment offers novel functions and qualities.

Adaptive product design

This type of design happens when the design team modifies a well-known solution to meet a new requirement, resulting in a novel application. For example, the latest metal 3D printing technology BMD combines material extrusion and metal injection moulding to create three-dimensional metal parts.

The core solution idea stays the same, but the concept’s embodiment is modified to meet and solve new challenges and criteria.

This Adaptive design shouldn’t be confused with web and graphical user interfaces adaptive design, which means that it adapts to different screen sizes, similar to responsive design.

Variant or Redesign

Engineering design is far more typically used to improve an existing design. For example, the objective might be to redesign a component in a product that fails in service or lower its manufacturing cost. Often, the redesign has no changes to the original design’s functioning principle or concept. For example, the form might be altered to lessen stress concentrations, or a different material could be replaced to save weight or cost.

When the redesign is accomplished by modifying some of the design parameters, it is commonly referred to as variant design.

The sizes and configurations of parts and assemblies vary within the constraints imposed by previously specified product structures, as is characteristic of size ranges and modular goods.

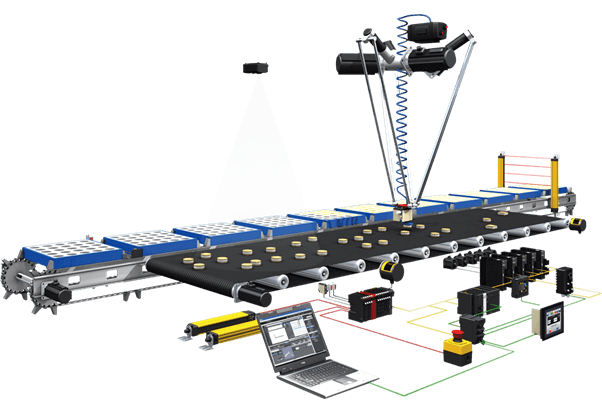

Selection product design

Most designs use conventional components generally referred to as Original Equipment Manufacturer (OEM), such as bearings, small stepper motors, and sensors such as mems microphones and accelerometers available from manufacturers and suppliers. As a result, the design work specifies suitable components that meet this scenario’s required performance, quality, and cost. Automation machines such as pick and place fall into this category.

Design Methodology in Engineering Product Design

Design methodologies form the blueprint for product design and development. They include systematic processes and approaches that guide engineers and product designers from ideation to production, incorporating principles like Design Thinking, Six Sigma, and Lean methodologies.

Agile and Iterative Design Processes – Agile approaches encourage adaptability and flexibility in design, enabling incremental adjustments based on ongoing input. It helps teams to iteratively improve products and react quickly to changes.

User-Centric Design Approaches – In user-centric design, the wants and experiences of the user come first. Ensuring the finished product meets user expectations entails developing empathy for people, identifying their issues, coming up with solutions, prototyping, and iterative testing.

Importance of Prototyping and Testing – Prototyping and testing are essential to creating a product, which is why they are so important. Prototypes offer concrete examples for assessment and improvement, and testing guarantees functionality, dependability, and user satisfaction while reducing risks before production.

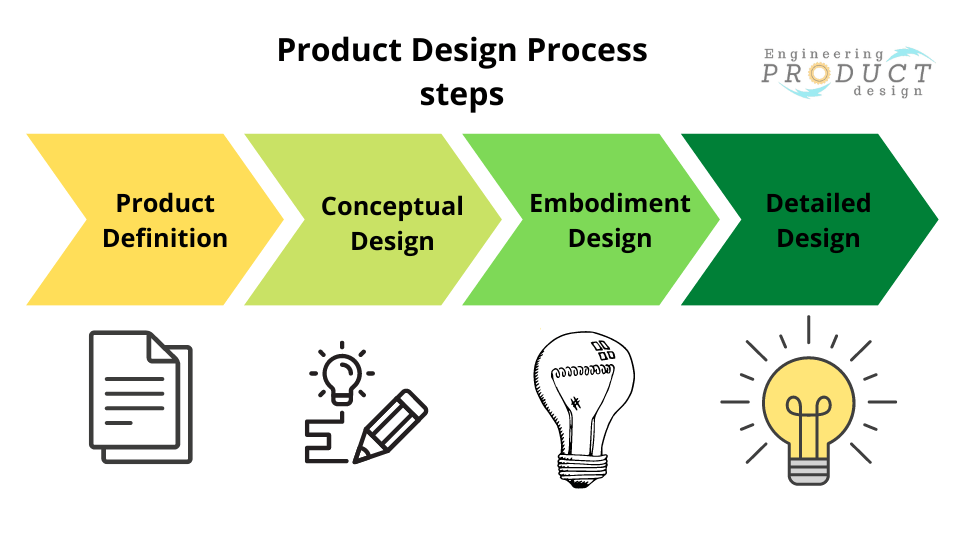

Product Design Processes

The engineering product design process is a series of steps that engineers and designers follow to develop a new product to manufacture and sell. Typically, these steps can be grouped into the following:

- Product definition

- Conceptual design

- Embodiment design

- Detailed Design

These four stages are then followed by manufacturing and production.

Product definition

The first step in the product design process is the product definition stage. This first step is crucial to understanding the requirements of the final product.

It is a pivotal phase where market dynamics, problem statements, objectives, and target users combine to create a comprehensive list of requirements into a Product Design Specification (PDS).

The product definition stage could be split into three crucial steps. Firstly, identifying requirements meticulously, followed by thorough information gathering. These culminate in crafting a Product Design Specification (PDS), a blueprint that encapsulates the product’s technical recruitments.

Consider the Tesla Model S, whose definition stage must have involved understanding customer wishes for a high-performance electric car. They would have clarified critical tasks, planned the car’s trajectory, and understood customer perceptions to define a sleek, efficient, and sustainable electric vehicle.

Conceptual design

Armed with a product design specification, the concept design stage is where product designers clarify the product requirements and explore ideas. These are then articulated into forms and functions in a broad outline concept.

Using sketching, brainstorming sessions, and conceptual prototyping to explore ideas, this phase thrives on imagination. Product designers define the issue, then brainstorm to carefully consider potential solutions and look outside the company for inspiration. In this case, the emphasis is on developing and carefully examining several concepts while evaluating their viability, capacity for innovation, and conformity to product design requirements.

Think back to Apple’s design process for the iPhone, where they would have generated numerous ideas and assessed them to produce a ground-breaking mobile device. User preferences, technology viability, and market trends must have been carefully considered throughout contemplation and concept selection.

Companies generally apply for patents to safeguard their designs and ideas at this stage. As the above shows, the Apple patent shows an idea for an edge-to-edge screen.

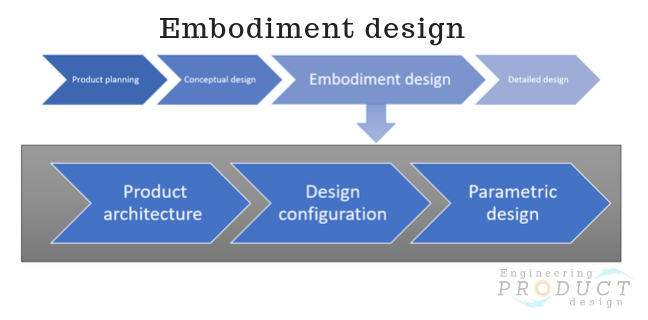

Embodiment design

The embodiment design step, which transforms chosen concepts into elaborate and detailed designs, is the refining element in the complex engineering product design. Here, the emphasis shifts to the technical details, materials, production methods, and compliance with regulations to turn conceptions into tangible prototypes.

Three separate steps make up this phase. Initially, specify the product’s architecture and set out the finer details of the design. These functionalities are then divided into modules and sub-systems by parametric design.

The two main architectural styles that influence product design are modular and integrated. As laptop designs have evolved, the modular approach makes it possible to use interchangeable parts, increasing versatility. Integral architecture combines components for streamlined looks and optimal performance at the same time.

Detail design

In engineering product design, the detailed design phase is the careful conductor that adjusts certain parts, measurements, tolerances, and assembly procedures to create a perfect orchestration. Accuracy is vital, and CAD models and simulations are master tools for fine-tuning and solidifying designs before manufacturing.

The groundwork established during conceptualisation and creativity is what this phase grows on. It is the furnace through which designs are put through arduous engineering analysis, optimisation, and validation. The detailed design ensures a smooth transfer from the blueprint to the production line by navigating the complexities of manufacturing preparation.

Examine the development of aviation engines: every bolt, blade, and channel is covered by meticulous design, which maximises both performance and safety. This phase ensures quality control and assurance at every stage. It exemplifies how design approaches work with the product design process.

Manufacturing and production

Converting the design into a physical product is the last step. Materials procurement, process setup for manufacturing, quality control, and production scaling for market distribution are all included in this.

As technology advances and customer expectations shift, the dynamic and varied field of engineering product design continues to change. As the world develops, cooperation amongst various disciplines, adherence to effective processes, and an unwavering emphasis on customer demands will continue to be essential for creating ground-breaking and influential goods that will influence our future.