Thermoforming is heating a plastic or glass sheet, shaping it to a specific shape in a mould, and trimming it to create a usable product.

Contents covered in this article

What is Thermoforming?

Thermoforming is a manufacturing process in which a thermoplastic or glass sheet is heated to a temperature where it becomes soft and flexible. Then, the sheet is pressed into and stretched over the mould using air (both vacuum and compressed) pressure or pressed between moulds using mechanical force to form the desired shape.

It’s very similar to vacuum forming but faster and is used extensively for higher-volume thermoplastics manufacturing. The final part might need trimming depending on the material, mould type, sheet thickness, and quantity.

Plastic thermoforming can be divided into two categories according to the material thickness.

- Thin gauge thermoforming (< 5 mm)

- Thick gauge thermoforming (> 3 mm)

As the name implies, the thin gauge process uses thin plastics to manufacture rigid or disposable packaging items such as plastic cups, food containers, lids, and blisters. In contrast, the thick-gauge process typically forms more durable cosmetic permanent parts such as vehicle door inside panels and electronics packaging.

Types of Thermoforming

Thermoforming can be broadly categorised into two types based on the material thickness:

Thin Gauge Thermoforming

Thin gauge thermoforming, involving materials less than 5 mm thick, is commonly used for producing items such as:

- Rigid Packaging: Plastic cups, food containers, and lids.

- Disposable Products: Blisters for medication or small consumer goods.

Thick Gauge Thermoforming

Thick gauge thermoforming, for materials greater than 3 mm thick, is used to manufacture more durable parts, including:

- Automotive Parts: Interior vehicle door panels.

- Consumer Electronics: Durable casings for electronic devices.

Thermoforming can be broadly categorised into two types based on the method of forcing the material down to the mould cavity.

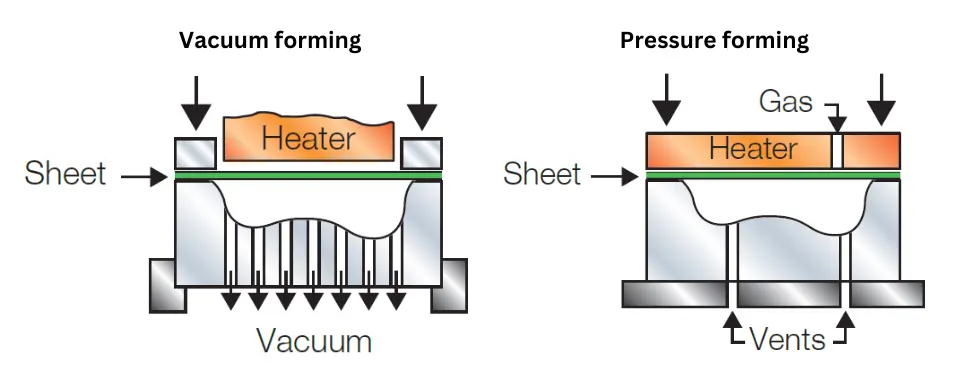

Vacuum Forming

Vacuum forming is a specific type of thermoforming where a heated plastic sheet is drawn onto a mould by vacuum pressure. It is one of the earliest thermoforming techniques used extensively due to its simplicity and cost-effectiveness.

Advantages:

- Cost-effective for low-volume production.

- Simple and quick setup.

Disadvantages:

- Limited to shallow parts.

- Less precise compared to other forming methods.

Pressure Forming

Pressure forming uses compressed air to force the plastic sheet into the mould, allowing for more intricate details and tighter tolerances than vacuum forming. It is ideal for applications requiring a higher level of detail and a textured surface.

Advantages:

- High detail and precision.

- Suitable for complex shapes.

Disadvantages:

- Higher tooling costs.

- More complex machinery is required.

Thermoforming materials

The most common thermoplastics used in the manufacturing process are;

| Material | Properties | Common Applications |

| Acrylic (PMMA) | High clarity, UV resistance, excellent optical properties, moderate impact strength | Displays, signs, skylights, automotive parts, light fixtures |

| Acrylonitrile Butadiene Styrene (ABS) | High impact resistance, good mechanical strength, excellent toughness and rigidity | Automotive panels, enclosures, luggage, medical device housings |

| Polycarbonate (PC) | Extremely high impact strength, good heat resistance, transparency | Safety helmets, machine guards, electronic components |

| Polyethylene Terephthalate (PET) | Excellent clarity, good barrier properties, lightweight, recyclable | Food and beverage containers, blister packaging, consumer goods |

| High Impact Polystyrene (HIPS) | Good impact resistance, easy to form, good printability | Food packaging, disposable cups, trays, refrigerator liners |

| Polypropylene (PP) | Good chemical resistance, high fatigue resistance, lightweight, good impact strength | Food containers, automotive parts, medical components |

| Polyvinyl Chloride (PVC) | Good chemical and corrosion resistance, high strength-to-weight ratio, good clarity (when rigid) | Packaging, construction materials, medical devices |

| High-Density Polyethylene (HDPE) | High strength-to-density ratio, good chemical resistance, low moisture absorption | Bottles, containers, automotive fuel tanks, industrial containers |

| Low-Density Polyethylene (LDPE) | High flexibility, low tensile strength, good chemical resistance | Bags, liners, stretch wrap, flexible containers |

| Polyethylene Terephthalate Glycol (PETG) | High clarity, good impact strength, easy to thermoform, chemical resistant | Medical devices, food packaging, consumer products |

| Polyetheretherketone (PEEK) | High thermal stability, excellent chemical resistance, high mechanical strength | Aerospace parts, medical implants, high-performance components |

| Polypropylene Copolymer (PPC) | Improved impact resistance and flexibility over homopolymer PP, good chemical resistance | Packaging, automotive parts, medical devices |

| Cellulose Acetate | High transparency, good toughness, moderate impact resistance, biodegradability | Tool handles, film base, eyeglass frames, packaging |

| Ethylene Vinyl Acetate (EVA) | Good flexibility, impact resistance, excellent clarity, good barrier properties | Medical tubing, sports equipment, packaging, footwear |

Applications of Thermoforming

Thermoforming is used across various industries, including:

Packaging – Thermoforming produces packaging solutions like blister packs and clamshells for consumer goods, pharmaceuticals, and electronics. Its ability to create lightweight, durable, and cost-effective packaging makes it ideal for high-volume production.

Automotive Industry – In the automotive sector, thermoforming creates interior panels, dashboards, and trunk liners. The process favours large, intricate parts with a high-quality finish.

Medical Devices – Thermoformed plastics are used in medical trays, diagnostic equipment housings, and protective casings for medical devices. The material’s sterility and flexibility make it suitable for various medical applications.

Consumer Products – From housings for electronic devices to durable outdoor equipment, thermoforming offers versatility in creating consumer products that require a combination of aesthetic appeal and structural integrity.

Common Issues and Troubleshooting in Thermoforming

Warping and Distortion

Warping can occur due to uneven heating or cooling of the material. Ensuring uniform temperature distribution and controlled cooling rates can mitigate this issue.

Material Defects

Defects such as bubbles or cracks can arise from improper material handling or contamination. High-quality, clean materials and maintaining a controlled environment can reduce these defects.

Inconsistent Thickness

Uneven stretching of the material can result in inconsistent wall thickness. Advanced forming techniques and accurate mould design can help achieve uniform thickness.

Advantages and Disadvantages of Thermoforming

Pros of Thermoforming

1. Cost-Effectiveness

- Lower Tooling Costs: Thermoforming typically requires less expensive moulds than injection moulding, making it more economical for small to medium production runs.

- Reduced Setup Costs: The initial setup and changeover costs are generally lower, making thermoforming ideal for prototypes and shorter production cycles.

2. Flexibility and Versatility

- Design Flexibility: Thermoforming can produce a wide range of part shapes and sizes, from simple to complex geometries, making it suitable for various applications.

- Rapid Prototyping: The ability to quickly create and modify moulds allows for rapid prototyping, facilitating faster product development and innovation.

3. Material Variety

- Diverse Thermoplastics: Thermoforming is compatible with many thermoplastic materials, including ABS, PVC, PS, PET, and polycarbonate. This variety enables manufacturers to choose materials based on specific properties such as durability, flexibility, and clarity.

- Specialty Materials: Advanced materials like bio-based plastics and high-performance polymers can also be thermoformed, expanding the application possibilities.

4. Efficiency in Production

- Scalability: Thermoforming is effective for both low and high-volume production. It can quickly adapt to changing production demands, making it suitable for different manufacturing scales.

- Short Cycle Times: The process has relatively short cycle times, enabling high throughput and efficient mass production, especially for large parts.

5. Production of Large Parts

- Large Part Capability: Thermoforming is advantageous for producing large, lightweight parts, such as automotive panels and large packaging solutions, which can be challenging to manufacture using other methods.

- Uniform Wall Thickness: It allows for consistent wall thickness across large areas, improving the structural integrity and performance of the final product.

6. High-Quality Surface Finishes

- Detailed Textures: The process can replicate intricate mould textures, producing parts with high-quality surface finishes, including gloss, matte, and custom textures.

- Aesthetic Appeal: Thermoforming can create visually appealing products with clean edges and smooth surfaces, enhancing the look and feel.

7. Simplified Post-Processing

- Minimal Finishing: Parts often require less post-processing, such as trimming and finishing, reducing labour and additional costs.

- Ease of Assembly: Features like undercuts, snaps, and fasteners can be incorporated into the mould, simplifying the assembly process for multi-part products.

Cons of Thermoforming

1. Limited Material Thickness

- Thickness Constraints: Thermoforming is generally limited to specific material thicknesses. Very thin or thick materials may challenge achieving uniform heating and forming.

- Wall Thickness Variability: Maintaining consistent wall thickness, particularly in deep-drawn or complex parts, can be difficult, leading to variations in part strength and performance.

2. Precision and Detail Limitations

- Less Intricate Detail: Unlike injection moulding, thermoforming may not achieve the same level of precision for complex or highly detailed parts. Fine details and tight tolerances are harder to replicate.

- Mould Design Restrictions: Certain design elements, like sharp internal corners or undercuts, are challenging to produce with thermoforming, limiting the complexity of part designs.

3. Material and Mold Constraints

- Thermoplastic Limitation: Thermoforming is restricted to thermoplastic materials, which may limit the range of mechanical and thermal properties available compared to other polymers.

- Mould Durability: Frequent use and high pressures can cause moulds to wear out, particularly if made from softer materials, necessitating maintenance or replacement.

4. Potential for Warping

- Warping Issues: Uneven heating or cooling can cause parts to warp or distort, affecting dimensional accuracy and consistency. Precise temperature control is crucial to avoid such issues.

- Cooling Control: Controlling the cooling rates to ensure uniform part quality adds complexity to the process and can affect the consistency of the final product.

5. Environmental Considerations

- Waste Generation: Although less wasteful than some processes, thermoforming generates trim and off-cuts that must be recycled or disposed of properly.

- Energy Consumption: The heating stages of thermoforming consume significant energy, which may have environmental implications if not managed efficiently.

6. Tooling Complexity

- Complex Molds: Producing detailed and accurate moulds for thermoforming can be complex and costly, especially for intricate designs or high-precision applications.

- Lead Times: Designing and manufacturing moulds can have longer lead times compared to simpler forming methods, potentially delaying production starts.

7. Limited to Sheet Materials

- Sheet Material Requirement: The process is restricted to forming from sheet materials, limiting its application to parts that start from a flat sheet. This constraint can affect the design and functionality of the final product.

- Sheet Thickness Limitations: The thickness of the starting sheet influences the final part properties, making it challenging to produce extremely thick or thin parts.

Comparison Table: Pros and Cons of Thermoforming

| Aspect | Pros | Cons |

| Cost | Lower tooling and setup costs | Complex moulds can be costly |

| Flexibility | Versatile designs, rapid prototyping | Less detail precision |

| Material Options | Wide range of thermoplastics, speciality materials | Limited to thermoplastics |

| Production Efficiency | Short cycle times, adaptable for different volumes | Thickness constraints |

| Part Size | Ideal for large parts | Limited to sheet materials |

| Surface Finish | High-quality finishes, detailed textures | Achieving consistent wall thickness can be challenging |

| Post-Processing | Minimal finishing required, ease of assembly | Warping issues, mould durability |

| Environmental | Low production waste | Energy consumption, waste management |

Frequently asked questions

Thermoforming vs. Injection Molding

Thermoforming and injection moulding are two popular methods for shaping plastics, each with advantages and applications.

Thermoforming

- Pros: Cost-effective for large parts, flexible for low to medium production volumes, and faster prototyping.

- Cons: Less precise for intricate details compared to injection moulding.

Injection Molding

- Pros: High precision, suitable for high-volume production, and consistent part quality.

- Cons: Higher initial tooling cost and longer setup time.

What is Glass thermoforming?

Thermoforming glass is a fairly new manufacturing process and came into prominence when Samsung introduced it through its flagship handset, Galaxy S6 Edge. Using glass is very similar to thermoforming plastics, but it differs because the glass is already cut to the right size, including the allowance needed for formed edges. It differs from glass blowing and is better suited for making flatter glass parts such as phone screens, glass tables and countertops.

What is Vacuum forming?

Vacuum forming is a type of thermoforming manufacturing process. The plastic is placed over a mould after being heated until it is soft and malleable. The plastic is then drawn onto the mould by a vacuum. The new shape is then formed by cooling the plastic until it becomes solid. The plastic can then be released from its mould by blowing the air back.

Vacuum forming is one of the earliest and most popular ways to handle plastic materials. Vacuum-forming products are ubiquitous and play a significant role in our daily lives. Plastic is frequently moulded into durable objects.