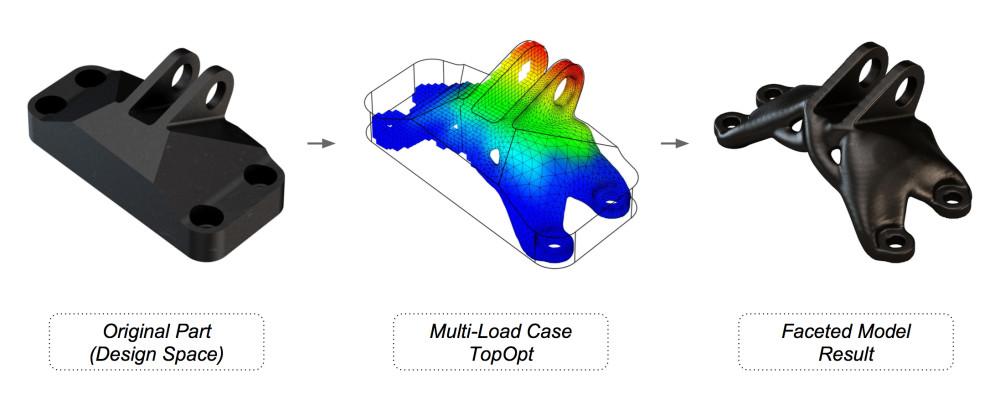

Topology optimization is a process that optimizes material layout within a given 3D geometrical design space for a defined user set of rules.

What is Topology Optimization?

Topology Optimization (TO) is a process that optimizes material layout and structure within a given 3D geometrical design space for a defined set of rules set by the designer. The goal is to maximize part performance by mathematically modelling and optimizing for factors such as external forces, load conditions, boundary conditions, constraints, and material properties within the design envelope.

Conventional topology optimization uses finite element analysis to evaluate the design performance and produce structures to satisfy objectives such as the following:

- Reduced stiffness-to-weight ratio

- Better strain energy to weight ratio

- reduced material volume to safety factor ratio,

- natural frequency to weight ratio.

Although topology optimization has a broad range of applications across industries, in engineering product design, it is used at the design stage of new product design to optimize the form to increase stiffness to weight ratio.

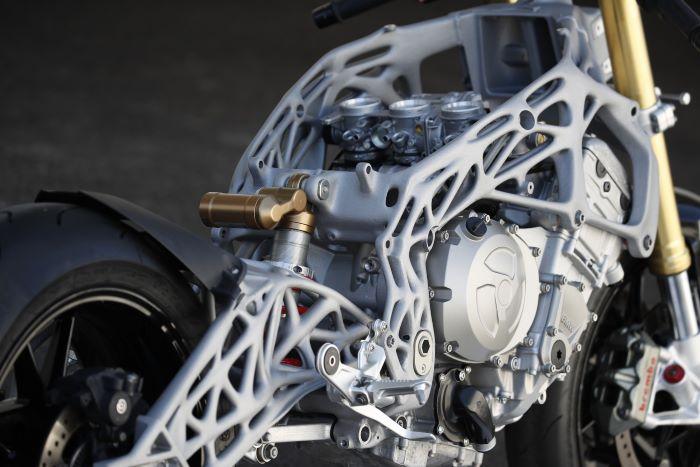

TO generated free form designs are often difficult to manufacture using traditional manufacturing methods.

But due to growth and technological advancement in additive manufacturing or so-called 3D printing, the design output by Topology optimization can be fed directly into a 3D printer. ( Read how 3D printing works in 7 easy steps here).

Since the start of the 21st century, the topology optimization concept has been commonly used in CAD software applications such as Solidworks, Autodesk, etc.

Topology optimization vs Generative design

So, what is the difference between Topology optimization and Generative design?

Topology optimization is often misunderstood and mixed-up with Generative design. Both product design techniques have become popular in the last decade and are often incorrectly assumed to be the same.

TO would require a design model from the user, along with inputs such as external forces, constraints, and material properties. The software then runs an FEA and removes the redundant material by analyzing the part to produce an optimized object. Hence topology optimization needs an engineering product designers’ initial model, limiting the possibility of the engineers’ knowledge to form part design.

On the other hand, Generative design uses topology optimization but takes the process a step further by removing the need for an initial model. The generative design creates its model by taking the inputs such as design space, forces, and constraints. Then its uses shape optimization to analyze and create multiple designs for the engineer to evaluate. Advanced generative design software such as Creo and Autodesk can automatically generate and compare numerous designs against the predefined set of rules.

This process would allow the engineering designer to quickly iterate hundreds of possible product design solutions to find the best optimized for given input criteria.

How does topology optimization work?

TO is often performed at the end of the design phase when the intended product must be lighter in weight. Hence the basic design model is already available to set up the TO analysis.

- First, the designer establishes the smallest allowed design space required for the part.

- Then user defines external loads, boundary conditions, constraints & material properties. At this stage, keep out areas or fixed locations are also specified.

- FEA then considers the minimum geometric design envelop and breaks down the design space into smaller areas such as applied load points, mounting locations, and constrained areas.

- TO creates a basic mesh of this smaller design space using finite elements. FEA then evaluates the mesh’s stress distribution and strain energy to find the optimum load or stress each element can handle.

- The TO program then digitally places pressure on the design from various angles, evaluates its structural integrity, and finds unneeded material.

- Then the software tests each finite element for stiffness, compliance, stress, deflection against the defined requirement to find redundant material.

- Finally, the finite element analysis knits the pieces together to complete the pattern.

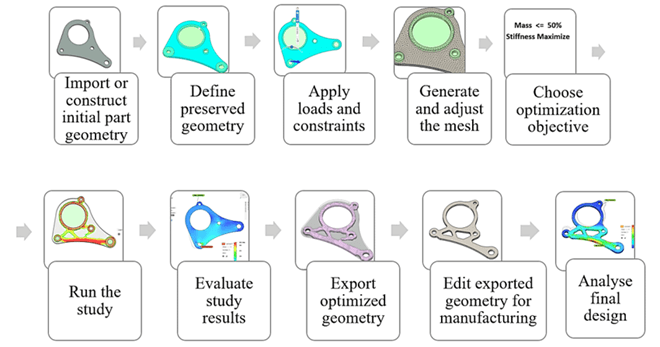

How to use topology optimization?

Following simple steps show how to use topology optimization in typical CAD software to create a simple bracket.

- Initial part geometry design – User creates a part frame or a design space

- Define preserved geometry areas – then the user defines some of the critical areas to keep such mounting screw headspace and material around bearing bore diameter

- Define loads, constraints, and material – The user at this stage apply loads and constraints. The part is also allocated a material and its properties.

- Generate and refine mesh – define and refine the meshing as it is one of the most critical steps in topology optimization

- Choose optimization objective – Decide and choose the purpose of the optimization.

- Run topology optimization – Software takes over and analyses the part to

- Evaluate the results – Evaluate the results but change the levels to identify the key areas FEA as highlighted to be critical

- Export optimized geometry –

- Edit exported geometry – to suit manufacturing

- Analyze the final part

Advantages and disadvantages of Topology optimization

Like any other design tool or product design process, TO has advantages and disadvantages.

TO advantages

- Optimized design – Most of the time, product design entails balancing factors and determining the best solution. Topology optimization aids with the quantification of the optimal design. FEA considers many factors and avoids making dangerous assumptions that might lead to faulty items.

- Minimize material – The most attractive benefit of topology optimization is its ability to reduce unnecessary material and increase the stiffness-to-weight ratio. Lower weight and size also result in smaller products and less energy consumption. In addition, the optimized design will reduce the raw material required hence sustainable for the planet.

- Cost-effective – The topology optimization designs will be cost-effective with a suitable manufacturing process. Because you are putting material only where necessary, minimizing the material usage and cost. It also saves on other factors such as packaging, less energy to move and transport. Many of the complicated geometries that result from topology optimization would render standard manufacturing processes impractical. However, when combined with 3D printing, this intricacy comes at no extra cost.

- Environmental impact reduction – Topology optimization design is sustainable as it produces less waste. But this might not be true if the incorrect manufacturing is selected. For example, the Topology optimization designs are more suitable for additive manufacturing. For Subtractive manufacturing, it is vital to start the design model as small as possible to minimize the material removal, minimizing wastage.

- Faster iterative design process – By running through various modes and considering the stressing of the components reduces the risk of failure.

- Shorter time to market

TO disadvantages

- Manufacturability limitations – Topology-optimized designs lend themselves better to additive manufacturing than subtractive manufacturing. Because in subtractive manufacturing, you need to remove material, hence it is time-consuming. Material wastage also drives the cost high.

- Higher cost – Since some of the optimized designs are only suitable for either 3d printing or, in some cases, injection moulding or die casting. However, AM cost is still high compared to some of the traditional manufacturing methods.

- Strength reduction – Since it was like any software, the output will hugely depend on user input. Hence in some cases minimising weight will reduce the strength.

- Lack of understanding – Although Topology optimization has been around for a couple of decades, only now, with the introduction of AM, it is coming to the fore. Tools are also being introduced, but it would still need time to mature and feed the industry.

Application of topology optimization

So why use topology optimization? Topology shape optimization tools provide the best means of optimizing a shape for a given requirement.

- Aerospace – TO is a natural fit for aeronautical engineering because of weight reduction.

- Automotive – TO in the automobile industry strikes a compromise between the desire for lightweight parts for increased fuel economy and power and the stability and strength of a body that can sustain torque and impact.

Topology Optimization Software

TO’s adaptability, speed, and robustness are becoming increasingly apparent to engineering product designers. Software businesses react by including the required toolkits in their existing products or by developing new software solutions.

- Altair Inspire & Altaire OptiStruct

- Ansys Mechanical

- Autodesk fusion

- Solidworks

- Creo

- nTopology

- Tosca Structure

- Comsol

- Nastran

Topology Optimization manufacturing methods

Topology form optimization allows for creating complicated structures with the optimum stiffness-to-weight ratio while utilizing the least amount of material. In addition, they may be made using both additive and subtractive manufacturing techniques.

AM does allow a considerable degree of freedom to the designer. Still, when flat items are involved, modern subtractive manufacturing processes such as milling, laser cutting, and water cutting can make components with complicated geometry just as well.

Each approach will impose distinct manufacturing limitations on element topology and geometry and how the manufacturing process will proceed with their development. The following are some techniques for producing these unique solutions:

- Additive manufacturing technologies

- CNC machining

- Laser cutting

- Water cutting

- Die casting

- Investment casting

Recommended Reading

Bends e, M. P., & Sigmund, O. (2003). Topology optimization: Theory, methods, and applications. Berlin: Springer.