Due to their adaptability, performance, and comparatively cheaper cost, some casting processes are widely used in manufacturing with many industrial applications. For example, Sand casting, Die casting, and Investment castings are widely used casting processes worldwide to make metal parts for the consumer, automobile, medical and aerospace industries.

Although all three manufacturing processes can produce good quality metal parts, one will suit your application more than the other because each procedure has its benefits and limitations. The ideal approach depends on your requirements, design complexity, materials’ characteristics, and other crucial elements of your part design.

Metal casting

What are Metal castings? Simply put, the casting process involves melting metal and pouring the molten material into a prepared mould to give it shape. Most casting techniques today vary in how the molten metal is handled and placed in the mould. Depending on the part design, casting processes can produce net-shaped parts. Therefore, no additional machining operations are required to achieve the part’s final required form and fit.

A product designer must know how each process functions and how it differs from one another to decide which is better for the component—sand casting, die casting or investment casting. The designer can only choose the most suited process for the application by being aware of its complexities, demands, and outcomes.

So let’s quickly review three casting procedures.

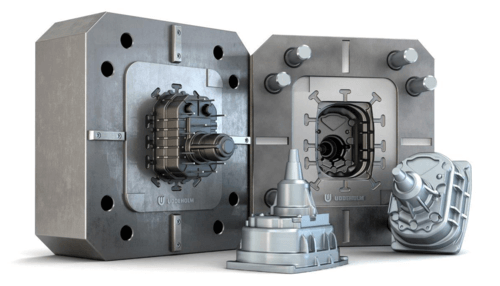

What is Die casting?

Die casting is a popular permanent mould metal casting process in which molten metal is forced into the mould at pressure, solidifying it into a metal cast. Die castings or pressure die castings, are commonly used in automotive housings, appliance components, and toys.

What Is Sand Casting

Sand casting differs slightly from Die casting. First, the molten metal is manually poured into an expendable sand mould, which cools into a 3D shape.

Complete guide to sand casting

What Is Investment Casting

In Investment casting, molten material is poured into a mould made from refractory material. Once the metal solidifies within the mould, casting is removed by breaking the refractory mould. A wax pattern is used to make a mould with refractory material.

Complete guide to Investment casting

What are the differences between Sand casting, Die casting and investment casting?

What are the differences between Sand casting, Die casting and investment casting?

Sand, Investment and Die casting are excellent choices for various applications. They are efficient, have comparable quality, and can cast similar material. As a result, determining a clear winner while assessing the differences between sand casting, Die casting, and Investment casting can be tricky.

However, some significant differences exist when deciding between the investment, die and sand-casting manufacturing processes. Therefore, knowing about them can benefit the product designer because it helps to make an informed decision.

Here are the eight most significant differences between the Sand, Investment and die-casting processes.

| Mould design and material | Material options |

| Part properties | Parts complexity |

| Wall thickness | Production volume |

| Tolerance and accuracy | Surface finish |

| Cost |

Mould design and material

The primary difference between Sand, Investment and die-casting processes is the material used to create the mould.

Die-casting moulds are permanent metal, whereas sand-casting moulds are expendable Sand. Investment casting requires special refractory coating around the wax pattern to make a mould.

Because of the permanent mould, Die casting has a quicker production rate than sand casting and investment casting, where the manufacturer has to remake the mould each time. Investment casting has the advantage of having more parts per mould, as multiple parts are cast in one tree.

The quality of the Sand used significantly impacts the casting surface quality. In contrast, the die-casting metal mould and fine slurry refractory material mould in investment casting would give you a smoother surface than sand casting.

Sand casting and investment casting moulds are destroyed every time, while the Die casting mould is ready immediately after a casting run. This quality and the methods’ fantastic processing speed are among the most important aspects. That is why die casting is generally preferred in high-speed production settings.

Because of this disparity, sand casting is less suitable for applications requiring speed. On the other hand, the process is relatively cost-effective and versatile, making it ideal for alloys and unusual shapes. In addition, designers have more freedom because the manufacturing process is simple and can easily handle a wide range of alloys.

| Metal casting types | Mould material and production |

|---|---|

| Sand casting | Expendable mould The mould material is Sand 1 – 2 weeks |

| Die casting | Permanent mould The mould material is metal 4 – 10 weeks |

| Investment casting | Expendable mould The mould material is a refractory material 7 – 10 days from wax pattern to a complete casting |

Material

Investment casting and sand casting can cast any material. However, die casting is generally used to cast parts from non-ferrous metals with a low melting point. Hence zinc, Aluminium, magnesium and brass are widely used in die casting, whereas aluminium alloy, brass alloy, cast iron, and cast steel are popular sand casting materials.

Investment casting is very similar to sand casting, which can cast any material.

| Metal casting types | Sand casting | Die casting | Investment casting |

| Castable metals | Unlimited | Low melting point metals | Unlimited |

Part properties

Die-casting parts are generally more durable than Sand and investment casting because of the high pressures involved with the process. In addition, the high pressure also ensures that there are no internal gaps and that the entire product is mostly free of any internal defects.

Die casting cools faster than Sand casting, giving die-cast parts a finer, more uniform microstructure. Typically this microstructure boosts mechanical properties by up to 20%.

- Sand casting – Material property is comparably poor

- Die casting – Good mechanical properties and microstructure due to high pressure

- Investment casting – Mechanical and microstructure depend on the casting method but typically fall between sand casting and die casting.

| Casting features and properties | Sand casting | Die casting | Investment casting |

| Part size – Weight (kg) – Min | 0.01 | < 0.01 | 0.001 |

| Part size – Weight (kg) – Max | No limit | 50 | 100 |

| Porosity (1 – best to 5 – worst) | 3 – 5 | 1 – 3 | 5 |

| Shape complexity (1 – best to 5 – worst) | 1 – 2 | 3 – 4 | 1 |

Parts Complexity

Another distinction between die, investment and sand casting results is the overall complexity of the parts. Investment and Sand casting can handle much more intricate and extensive designs than Die casting. Die casting provides much greater dimensional accuracy and speed but is limited in its ability to produce complex shapes.

Investment and Die casting are also limited and are suitable for small to medium size parts compared to Sand casting.

| Casting features and properties | Sand casting | Die casting | Investment casting |

| Part size – Weight (kg) – Min | 0.01 | < 0.01 | 0.001 |

| Part size – Weight (kg) – Max | No limit | 50 | 100 |

| Shape complexity (1 – best to 5 – worst) | 1 – 2 | 3 – 4 | 1 |

Wall Thickness

Sand casting generally results in thicker walls. Thick walls mean more room to correct errors through machining and other post-processing but are also heavier.

| Casting process | Section thickness Minimum | Section thickness Maximum |

| Sand casting | 3.00 mm | No limit |

| Die casting | 0.50 mm | 12.00 |

| Investment casting | 1.00 mm | 75.00 |

Die casting, on the other hand, produces thinner walls while maintaining greater dimensional accuracy. As a result, sand casting is unsuitable for small objects with tight tolerances and maintaining consistency and delivering the best results becomes extremely difficult. Investment casting can also produce thin walls and is a good choice for complex shapes and features.

Production Volume

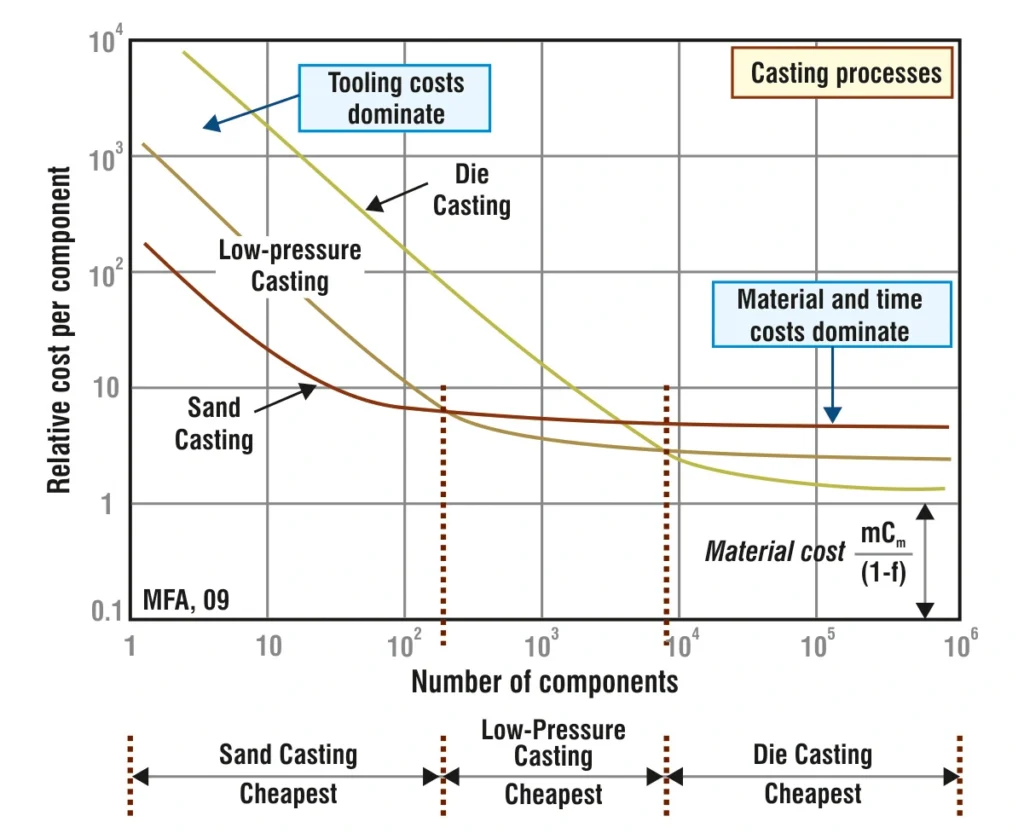

One of the benefits of sand casting is that it has fewer tooling requirements. As a result, the process takes comparably quicker and can yield good results immediately. Die casting, on the other hand, is best suited for high-volume production due to its more complex and time-consuming initial tooling.

Investment casting can produce more parts per batch because multiple parts can be cast per tree, but the initial set-up time is similar to Die casting.

| Casting features and properties | Sand casting | Die casting | Investment casting |

| Typical production rate (parts/mould hour) | 1 – 20 | 2 – 200 | 1 – 1000 |

| Minimum quantity | 1 | 10,000 | 10 |

However, remember that die casting is a faster process for large volumes. Fast production means Die casting will allow you to produce a thousand pieces in less time than the alternative method. However, the initial tooling time required for die casting makes the other process better if you only need 100 – 150 or fewer products.

Tolerance and accuracy

Die casting offers the best tolerance accuracy out of the three castings. These are typical for Aluminium as the casting process’s accuracy and tolerance depend on factors such as the following.

- Design Complexity

- Type of pattern equipment and die equipment

- Metal and allow used

- Pattern and die condition

- Foundry working methods

| Dimension | Die Casting | Sand casting | Investment Casting |

| Up to 25mm | +/- 0.050mm | +/- 2.00mm | +/- 0.250mm |

| Up to 50mm | +/- 0.075mm | +/- 2.00mm | +/- 0.350mm |

| Up to 75mm | +/- .0.100mm | +/- 2.00m | +/- 0.400mm |

| Up to 100mm | +/- 0.125mm | +/- 3.00mm | +/- 0.500mm |

Refer to the following standards for casting tolerance and accuracy charts and tables.

- ISO 8062 – Casting dimensional tolerance and machining allowances

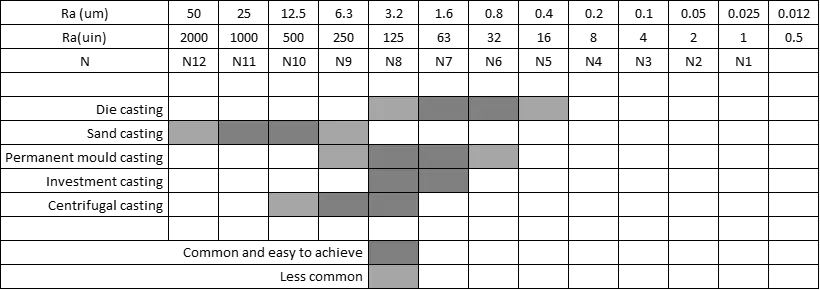

Surface Finish

Another critical factor is the final product’s surface finish. The sand casting process produces a coarse and rough surface that may require further treatment or machining after cooling. Die casting, however, has an excellent surface finish that rarely requires additional treatment.

Investment casting typically produces an excellent surface finish due to fine slurry material.

Cost

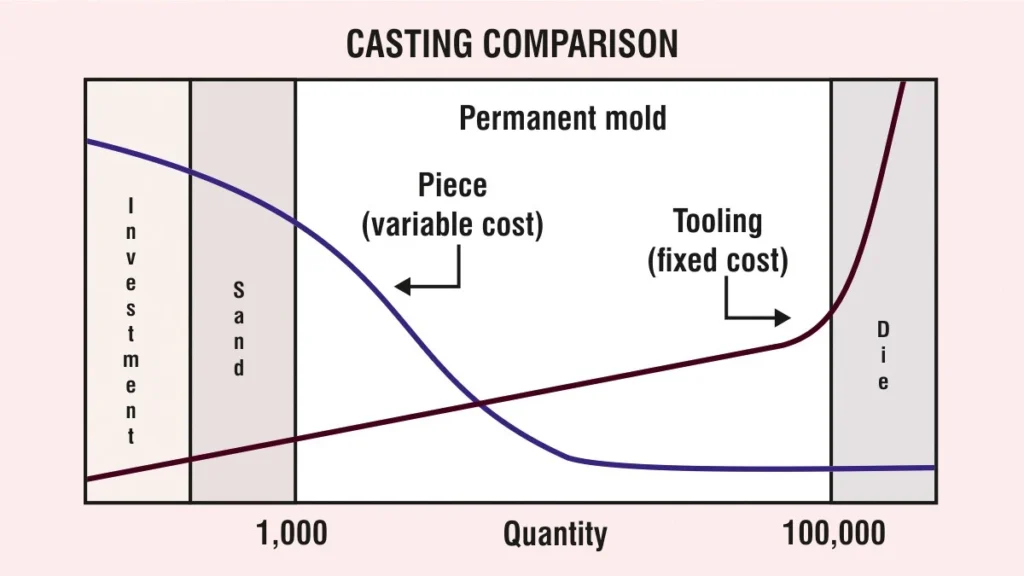

Like all manufacturing processes, the unit cost depends on various factors, including material, labour and equipment. For example, sand casting requires more labour than others, Die casting requires expensive dies and machinery, and Investment casting requires long production times.

Compared to the simplicity of Sand, making a metal mould for the die-casting process costs more. In addition, metal moulds necessitate more time and expertise, raising the overall cost of the process.

| Casting process | Die Cost | Equipment cost | Labour cost | Product rate (pieces/h) |

| Sand casting | Low | Low | Low – Medium | < 20 |

| Die casting | High | High | Low – Medium | < 200 |

| Investment casting | Medium to High | Low to Medium | High | < 1000 |

Development time also varies between the casting processes and increases the overall cost.

- Sand casting – 2-10 weeks of development time

- Die casting – 12 – 20 weeks

- Investment casting – 5 – 16 weeks

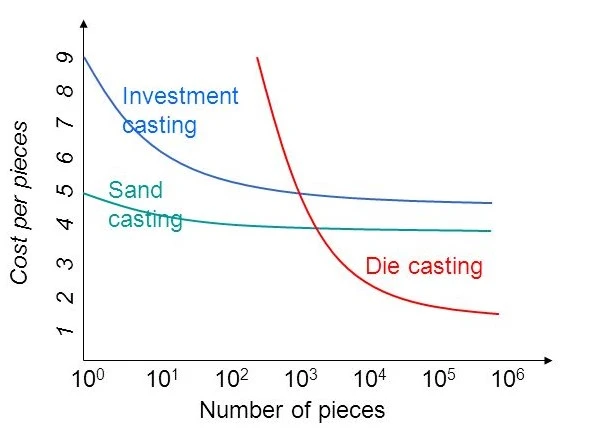

The image below shows that the cost depends on the production quantity and rate.

Advantages and disadvantages of Sand, Die and Investment casting

| Casting type | Advantages | Disadvantages |

| Sand casting | Almost any metal can be cast There is no limit to part size, shape or weight. Low tooling cost | Finishing required Coarse surface finish Wide tolerance |

| Die casting | Excellent dimensional accuracy Excellent surface finish Low porosity High production rate | High die cost Limited part size Generally limited to non-ferrous metals Long lead time |

| Investment casting | Intricate part shapes Excellent surface finish and accuracy Almost any metal can be cast | Part size limited Expensive patterns and mould Expensive labour |

Characteristics of Sand, Die and Investment casting

| Casting features and properties | Sand casting | Die casting | Investment casting |

| Part size – Weight (kg) – Min | 0.01 | < 0.01 | 0.001 |

| Part size – Weight (kg) – Max | No limit | 50 | 100 |

| Typical surface finish (Ra- um) | 5 – 25 | 01-Feb | 0.3 – 2 |

| Porosity (1 – best to 5 – worst) | 3 – 5 | 1 – 3 | 5 |

| Shape complexity (1 – best to 5 – worst) | 1 – 2 | 3 – 4 | 1 |

| Dimensional accuracy (1 – best to 5 – worst) | 3 | 1 | 1 |

| Section – Wall thickness – Min | 3 | 0.5 | 1 |

| Section – Wall thickness – Max | No limit | 12 | 75 |

| Typical dimensional tolerance (mm) | 1.6 – 4.00 | +/- 0.001 – 0.005 | +/- 0.005 |

| Typical production rate (parts/mould hour) | 1 – 20 | 2 – 200 | 1 – 1000 |

| Minimum quantity | 1 | 10,000 | 10 |