Molten metal is poured into a desired geometrical shape mould cavity and cooled to produce a solidified object in metal casting.

What is Metal Casting?

Metal casting is a manufacturing process that involves pouring molten metal into a mould to create a 3D metal part. The mould contains a hollow cavity of a desired geometrical shape, and the molten metal is allowed to cool down to form a solidified part.

The term ‘casting’ also refers to the part made by the casting process, which dates back 6000 years. Historically it is used to make complex and large parts, which would have been difficult or expensive to manufacture using other manufacturing processes.

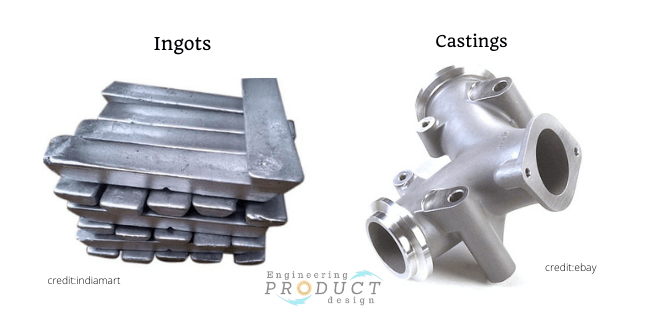

Primarily, casting produces ingots and shapes. An ingot is a casting produced into a simple shape intended for further processing, such as metal extrusion and forging. Shape casting is for near or net shape castings to produce complex geometries closer to the final part.

Some casting processes can produce Net-shape parts. No additional manufacturing operations are required to achieve the required geometry and dimensions for the parts. Other casting processes are Near-Net-Shape, which requires some other shaping processes, typically machining, to achieve accurate features such as threads, o-ring grooves, bearing seating and pilot holes of self-tapping screws.

Types of Metal Casting

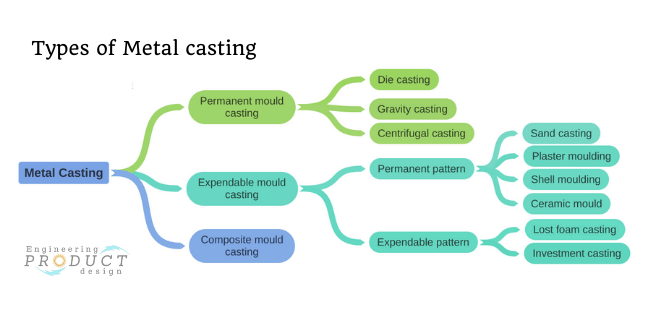

Metal casting falls into two groups by the fundamental nature of the mould design. i.e. expendable mould and permanent mould castings. It can be further subdivided into groups depending on its pattern material.

- Expendable mould

- Permanent mould

- Composite mould

Consider the following factors before choosing a suitable metal casting for a given engineering product design;

- Part shape and size

- Required quantity

- Required tolerance

- Material

Sand casting, Die casting and Investment casting are widely used across various industries.

Expendable mould casting

Expendable mould casting uses a temporary non-reusable mould to produce the final casting, as the foundry breaks the mould to get the casting out. Sand, clay, and plaster are common materials used to make these moulds. To improve the qualities of disposable moulds, binders known as bonding agents are typically used. Expendable mould casting can be used to cast complex, sophisticated shapes.

Types of Expendable mould casting

- Permanent pattern

- Sand casting

- Plaster moulding

- Shell mould

- Ceramic mould

- Expendable pattern

- Lost foam

- Investment casting

Sand casting

Sand casting is the most common example of Expendable mould casting, which generally uses permanent patterns to create the mould. Molten metal is poured into an expendable sand mould cavity by gravity or force, which then solidifies to form the cavity shape part.

Sand casting is described in detail under the “Guide to sand casting” section.

Plaster mould casting

In Plaster mould casting, the mould is made of plaster of Paris instead of sand and works similarly to sand casting.

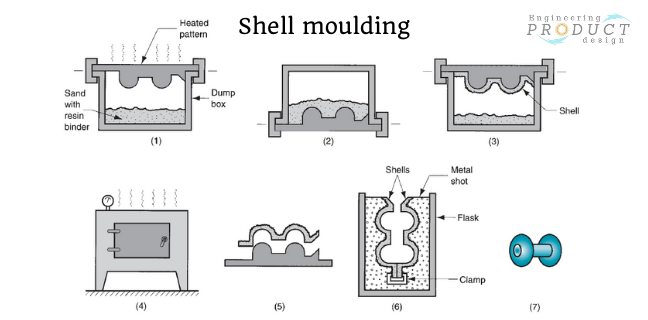

Shell moulding

Shell moulding uses a thin shell mould, approximately 9 mm (3/8″). The mould is sand bound together using a thermosetting resin binder. The image below shows a typical Shell moulding process.

Shell moulding steps

- A heated match plate or cope-and-drag metal pattern is placed over a sandbox mixed with a thermosetting resin.

- The box is then turned upside down to allow the sand and resin to fall onto the hot pattern. This creates a partially cured mixture to form a hard shell on the surface of the pattern.

- The box is then repositioned so that loose, uncured particles fall away.

- The sand shell is cured by heating it in an oven for several minutes.

- The shell mould is removed from the pattern.

- The shell mould’s two halves are assembled, supported by sand or metal shot in a box, and pouring is completed.

- The finished casting without the sprue.

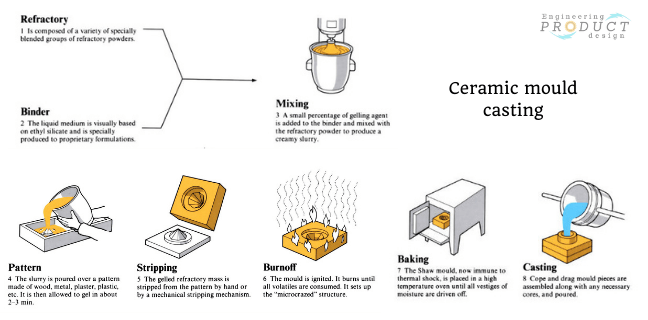

Ceramic mould casting

Ceramic mould casting is very similar to sand or plaster mould casting, except the mould is made of refractory ceramic material. The ceramic material can withstand high temperatures compared to the plaster mould. Hence it is used to cast materials such as cast steels, cast irons and other high-temperature alloys.

The process is described in detail here – “Guide to ceramic mould casting“

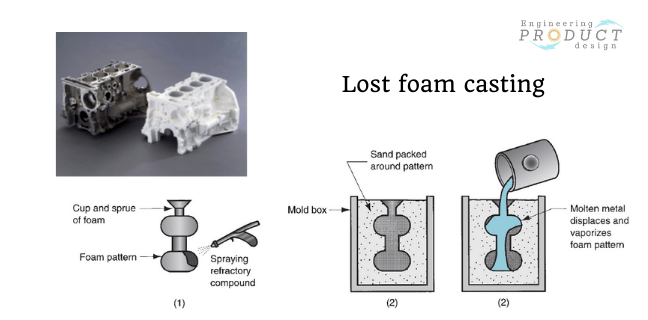

Lost foam casting

Lost foam casting uses a polystyrene foam pattern to create a sand mould. The pattern then vaporises when the molten metal is poured into the mould. Lost foam casting is sometimes called Expanded polystyrene casting, lost pattern process or evaporative foam casting.

Lost foam casting process steps

- The polystyrene pattern is coated with a refractory compound

- The foam pattern is then placed in the mould box, and sand is compacted around it. The pouring cup and sprue are formed by pouring molten metal into the pattern portion that forms the pouring cup and sprue.

- Poured molten metal vaporises the polystyrene pattern as the metal enters the mould, filling the resulting mould cavity.

Investment casting

In investment casting, a wax pattern is coated with a refractory material to make a mould, which is melted away before pouring molten metal into the cavity to solidify.

Under the “Guide to investment casting” section, Investment casting is described in detail.

Permanent mould casting

Sometimes called non-expendable mould casting, permanent mould casting uses permanent moulds reused after each production cycle. Although permanent mould casting produces repeatable parts due to the reuse of the same mould, it can only produce simple castings as the mould needs to be opened to remove the castings.

- Gravity casting

- Low pressure/vacuum

- Die casting

- Centrifugal casting

Permanent mould casting types

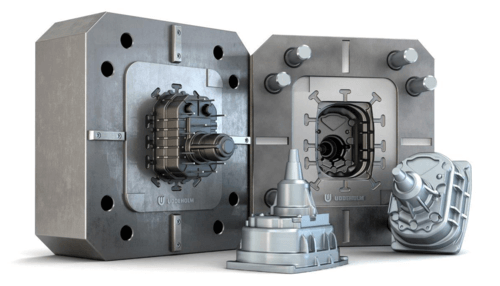

Die casting

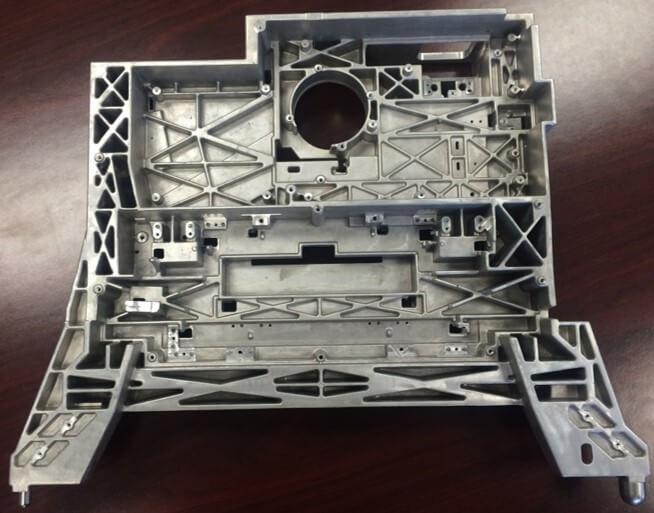

Die casting is a permanent mould metal casting method in which liquid metal is poured into the “Dies” at pressures ranging from 0.7 to 700 MPa, where it solidifies as a metal cast.

Die casting is described in detail under the “Guide to Die casting ” section.

Gravity casting

The molten material is poured into the mould from a crucible only under gravity in gravity casting.

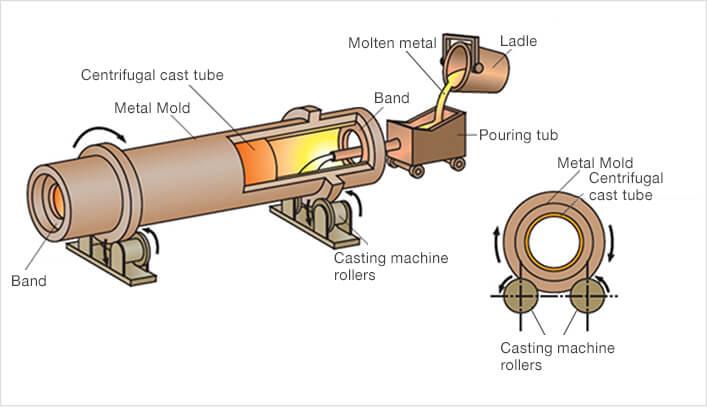

Centrifugal casting

Centrifugal casting refers to many casting procedures that employ rotational centrifugal forces to transport molten metal to the outer parts of a circular mould cavity, where it solidifies to form a product. Centrifugal casting is described in detail under the “Guide to Centrifugal casting ” section.

Composite mould casting

As the name suggests, these use both expendable and re-useable casting moulds to produce castings. These typically include materials such as sand, wood, graphite and metal.

Application and Characteristics of Metal casting

Nearly every engineering product we use, from washing machines to pillar drills, cars to bicycles, are manufactured using metal parts that are most likely to be made using one of the metal casting processes. This age-old manufacturing process has improved its precision and tolerances over time.

Typically, castings are used to make car engine blocks, crankshafts, and power tool housings such as pillar drills, plumbing parts, turbine blades, metal statues, gears, and gearbox housings.

| Process | Advantages | Disadvantages |

| Sand casting |

|

|

| Plaster mould |

|

|

| Shell moulding |

|

|

| Ceramic mould |

|

|

| Lost Foam casting |

|

|

| Investment casting |

|

|

| Die casting |

|

|

| Gravity casting |

|

|

| Centrifugal casting |

|

|

How does metal casting work?

Elements of the gating system

The most crucial element of a metal casting setup is the mould. Mould contains a hollow cavity of the desired cast part shape. Foundry makes the size and shape of the cavity marginally oversize to allow for casting shrinkage during the solidification process.

Shrinkage depends on the design, size, shape, and material used; hence, getting a foundry involved during the design process is crucial.

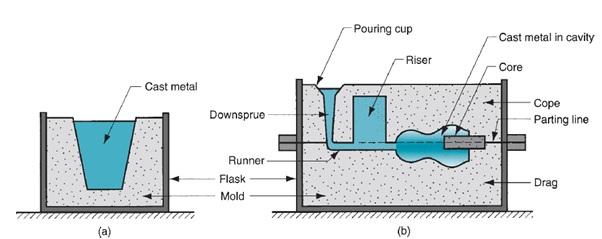

The image below shows two types of moulds: Open mould and Closed mould. Open mould, as the name suggests, has an open cavity.

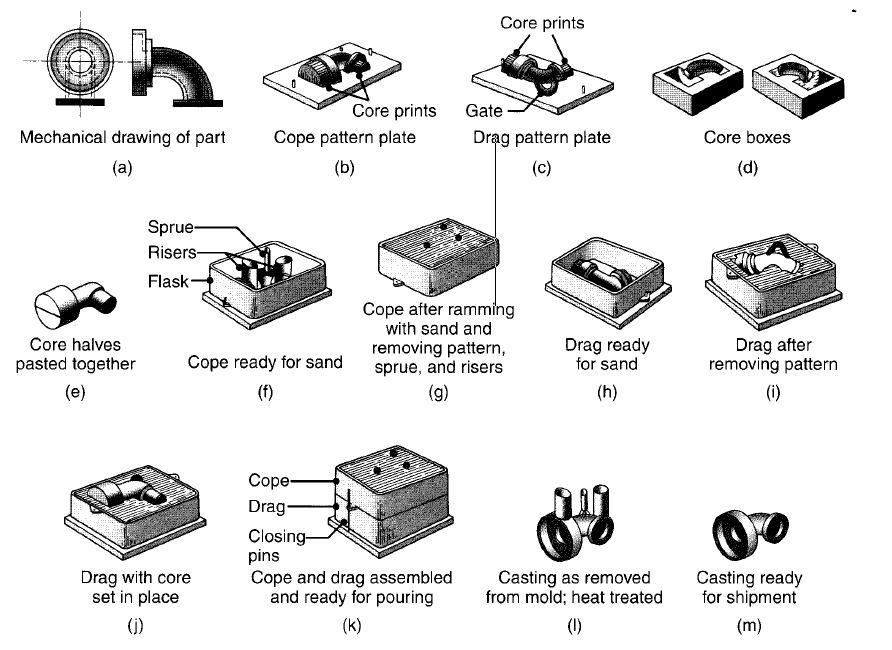

One of the most common metal casting processes is Sand casting, and they are a prime example of closed mould casting.

The closed mould consists of two halves inside a box called a Flask, the upper half is called the Cope, and the bottom half is called the Drag. The flask is also divided into two halves. The line that separates the two halves is called the parting line.

The gating system is the channel or path the molten metal flows into the cavity. As shown above, the gating system consists of a pouring cup and a down sprue through which the metal enters the runner that leads into the central cavity. The pouring cup minimises the splash and turbulence when the metal flows through the sprue, which is tapered to aid the flow. However, most of the casting suffers from shrinkage during cooling, and to minimise the shrinkage issue, a riser is used. A riser is a simple reservoir in the mould that feeds molten material to the shrinking sections to compensate as it solidifies. There are four different risers types: top riser, side riser, blind riser, and open riser.

Metal casting steps

- Patternmaking – A replica of the part to be cast is made using a suitable material such as wood, metal, plastic or plaster.

- Mould making – Mould making is a multi-step process in which patterns and cores are used to create a mould. The type and how the moulds are made would vary depending on the type of metal casting. For example, sand casting uses sand inside a flask to create moulds and die casting uses hardened tool steel moulds.

- Metal melting & pouring – Liquid is then melted and poured into the mould cavity either by gravity or high pressure. Then the cast is allowed to solidify before the cast parts are removed from the mould. Again, the cast part removal varies depending on the type of metal casting.

- Post-processing – The cast metal object is removed from the mould and fettled in this final step. The object is cleaned of any moulding material during the fettling, and rough edges are removed.

Material suitability

Although almost all metals can be used, the most common ones are iron, steel, aluminium, magnesium and copper-based alloys such as bronze.

Zinc, aluminium, magnesium and brass are widely used in die casting, whereas aluminium alloy, brass alloy, cast iron, and cast steel are popular sand-casting materials.

Advantages and disadvantages of metal casting

Because of the above reasons, metal casting is a crucial net-shape manufacturing technology. Others include net-shape forging, sheet metal stamping, additive manufacturing and metal injection moulding. As with any other manufacturing process, a basic understanding of the process, its underlying science, and its pros and cons are essential for manufacturing low-cost quality engineer products.

Advantages of metal casting

- Metal casting can produce complex shapes

- Features like internal cavities or hollow sections can be easily cast

- Significant components can be produced in a one-piece cast

- Materials that are difficult or expensive to manufacture using other manufacturing processes can be cast

- Compared to other manufacturing processes, casting is cheaper for medium to large quantities

- Almost all metals can be cast

- Near net shape often without or minor post-processing

Disadvantages of metal casting

- Relatively coarse surface finish and hence wider tolerance has to be allowed and is not suitable for mating interfaces

- Metal casting, such as shell moulding, has a limit in terms of size and the pattern

- Patterns are time-consuming and expensive to make, although additive manufacturing processes such as binder jetting are being used lately to make a mould

- Die casting can be very expensive for smaller to medium quantities due to the high die cost

- Part size and material choices depend on the casting process chosen. For instance, only nonferrous metal can be used for permanent mould castings

References and recommended reading

- Beeley, P. (2001). Foundry Technology (Second edition ed.). Oxford: Butterworth Heinemann.

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering & Technology (Sixth Edition ed.). London: Pearson.

- Groover, Mikell P.(2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems (Forth edition ed.). Hoboken, NJ: J. Wiley & Sons, 2010.

- Ashby, M.F., 2005. Material Selection in Mechanical Design. 3rd ed. Oxford: Butterworth-Heinemann.