Thermosets and Thermoplastics sound similar, but their properties and applications differ vastly. Therefore, engineering product designers must understand the difference in performance between a thermoset and thermoplastic, which would help make better design and sourcing decisions and improve the quality of your products.

What are the differences between Thermoset and Thermoplastic?

Both thermosets and thermoplastics are polymers, but the main difference is how they react to heating. Thermoplastics can be remelted into liquids, whereas thermoset plastics are always solid once cured. For example, after curing, thermoplastics can melt under heat again, whereas thermoset plastics retain their shape and remain solid.

Consider thermoplastics like butter, where you can melt and cool from liquid to solid and vice versa. On the other hand, a Thermoset is like a cake in that once it reaches its final state after baking, any additional heat causes charring and burning, not melting.

Because of their low melting point, thermoplastics are ideal for recycled material applications. In contrast, thermoset plastics can withstand high temperatures without losing shape, making them more durable in high-temperature applications.

What are Thermoplastics?

Thermoplastic polymers, also known as thermoplastics (TP), are solid at room temperature but become viscous liquid when heated, eventually becoming fluid due to crystal melting or crossing the glass transition temperature. Because it can be softened by heating and processed using manufacturing processes like injection moulding, extrusion, blow moulding, and thermoforming.

This property enables them to quickly and cheaply form into products using manufacturing processes like extrusion, thermoforming, and injection moulding. Furthermore, they can repeatedly be subjected to this heating and cooling cycle without significant polymer degradation.

Polyethene (PE), polycarbonate (PC), and polyvinyl chloride (PVC) are common thermoplastics, as are polypropylene (PP), polystyrene (PS), and polyethylene terephthalate (PET). However, thermoplastics generally resist shrinking while providing good elasticity and strength. As a result, thermoplastics, used in applications such as industrial machine components and retail plastic bags, can soften, deform, and lose some physical properties when exposed to high temperatures.

Advantages and Disadvantages of Thermoplastics

The various thermoplastics used for injection moulding have many benefits and drawbacks for specific applications. However, thermoplastics share some general advantages and disadvantages.

Advantages of Thermoplastics

- Excellent metal adhesion

- and aesthetic finish

- Recyclable and reshapable with minimal impact on material properties

- Chemical and detergent resistance

- Adequate electrical insulation

- High resistance to impact

- improved anti-slip properties

- It is possible to create both rubbery and hardened crystalline surfaces

- Energy efficient manufacturing

- Low-cost, high-volume manufacturing with excellent precision

- Various types can replace metals with significant weight saving

- Greater deflection tolerance without deformation than most metals

- Chip-resistant and corrosion-resistant

These benefits make thermoplastics ideal for a wide variety of designs and applications. However, the following thermoplastic disadvantages may influence material selection:

Disadvantages of Thermoplastics

- Due to softening when heated, it is not suitable for all applications

- Thermoplastics degrade more quickly in direct sunlight or when exposed to UV light

- Some thermoplastics are more resistant to hydrocarbons, organic solvents, and polar solvents than others

- Long-term loading causes creep in some types of thermoplastics

- Under high stress, Thermoplastics can fracture rather than deform

- More expensive than thermosets

Thermoplastics materials

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- Polycarbonate + Acrylonitrile Butadiene Styrene (PC/ABS)

- High Impact Polystyrene (HIPS)

- Polyphthalamide (PPA)

- Polymethyl Methacrylate Acrylic (PMMA)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Polyoxymethylene (POM)

Thermoplastics applications

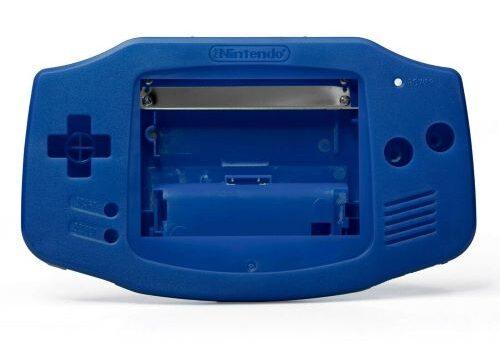

A thermoplastic is any plastic that melts into a soft, pliable state at a specific temperature and solidifies when cooled. These materials are re-meltable and recyclable, typically stored as pellets before moulding. Acrylic, nylon, polyester, polypropylene, polystyrene, and Teflon are common thermoplastics. They are widely used in various industries and products, from clothing and cookware to carpets and laboratory equipment. Thermoplastics are commonly used in 3D printing too.

What are Thermoset plastics?

Thermoset plastics are usually liquid at room temperature and harden when heated or treated chemically. Hardening is because they form permanent chemical bonds during the curing process. They are also known as thermosetting resins or thermosetting polymers.

They are typically manufactured by Reaction Injection Moulding (RIM) or resin transfer moulding (RTM). When heated, thermoset plastics take on a specific shape, though overheating can cause them to degrade without entering the fluid phase.

Because of their greater structural integrity and resistance to heat and chemicals, thermoset plastics are ideal for use when heat is a factor, such as in electronic housings and appliances or chemical processing equipment. In addition, common thermosets such as epoxy resins, phenolic, and polyimide can withstand deformation and impact and are frequently used in composites.

Advantages and Disadvantages of Thermosets

Advantages of Thermosets

- Capable of being moulded with various tolerances

- Allows for more versatile product designs

- Variable wall thicknesses improve structural integrity.

- Typically, less expensive than metal components

- Outstanding electrical insulation properties

- Exceptional heat resistance at high temperatures

- resistant to corrosion

- Excellent dimensional stability at a wide temperature range

- Thermal conductivity is low

- Setup and tooling costs are lower compared to thermoplastics

- Excellent strength-to-weight ratio

- Water repellent

- A wide range of colours and surface finishes are available.

Disadvantages of Thermosets

- It cannot be reshaped, remoulded, or recyclable.

- Good surface finishing is much more challenging to achieve

- Thermal conductivity is poor for housing replacements.

- When used in high-vibration applications, the material’s rigidity can lead to product failure.

Thermoset materials

- Vulcanized Rubber

- Urea Formaldehyde

- Bakelite

- Polyresin or Polyester resin

- Melamine-Formaldehyde Resins

- Epoxy Resins

- Polyimides

- Silicon resins

- Polyurethane

- Furan Resins

Thermosets applications

Epoxy, polyurethane, and silicone are examples of thermoset plastics, as are materials such as polyester. Thermoset plastics are kept in liquid form, and different thermosets provide different benefits. Epoxies, for example, are tough, elastic, and chemically resistant, whereas phenolic is flame resistant.

Thermoset & Thermoplastic Differences

Thermoset & Thermoplastic materials

| Thermoplastic Materials | Thermoset Materials |

| Polycarbonate | Polyester |

| Acetal | Polyurethane |

| Polyvinyl chloride | Silicone |

| Acrylic | Epoxy |

| Nylon | Vulcanized rubber |

| Polyethylene | Melamine resin |

Thermoset & Thermoplastic features

Aesthetically, thermoplastics are preferred over thermoset polymers; however, thermosetting materials are preferred over alternatives such as metals.

Thermoset materials enable in-mould painting, where the moulder sprays paint or unique coats directly into the mould before the moulding cycle. This technique improves material adhesion and prevents chipping, cracking, and flaking, even in harsh weather conditions.

Thermoset polymers are generally more robust and rigid than thermoplastic polymers, which soften when heated. Because of their covalent solid crosslinks, thermosets do not soften and have better dimensional stability than thermoplastics.

Because of the three-dimensional network of bonds, or crosslinks, created during the manufacturing process, thermoset plastics are more rigid than thermoplastics. As a result, Thermosets are better suited to high-temperature applications because they retain their shape as solid covalent bonds between polymer chains—the greater the crosslink density, the greater the resistance to heat degradation and chemical attack. Higher crosslink density improves these materials’ mechanical strength and hardness but can also cause brittleness.